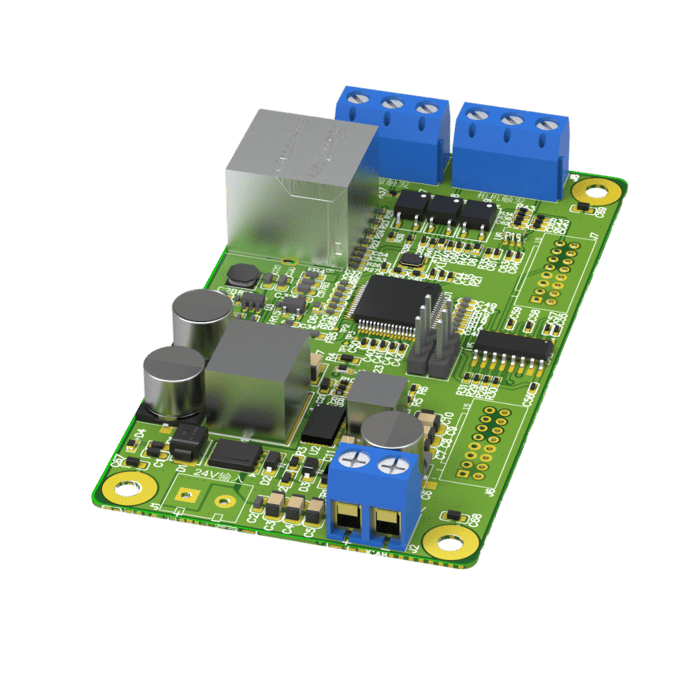

Inline SMT AOI

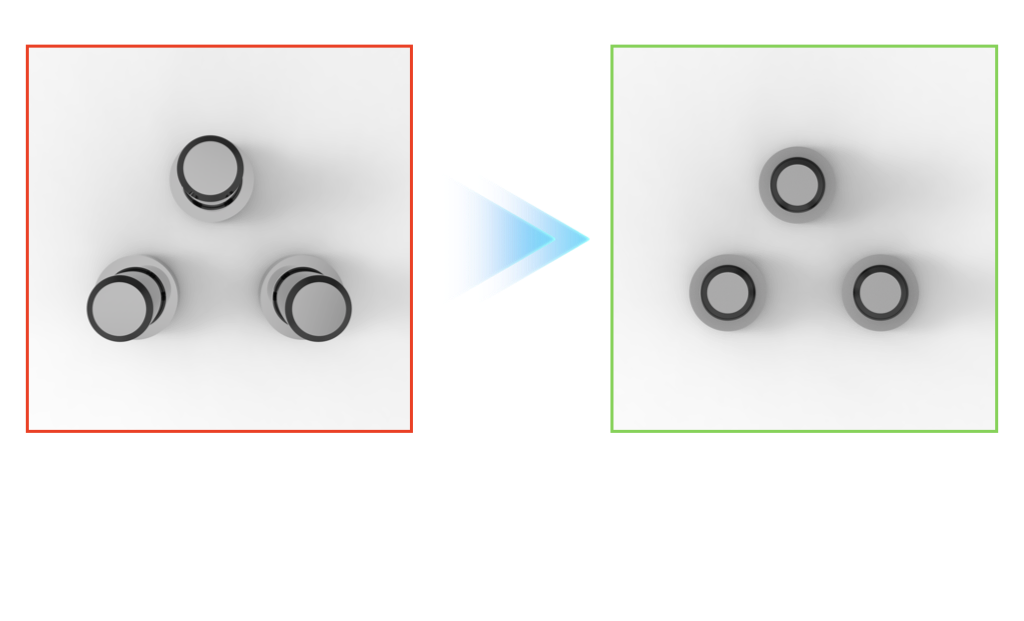

Reliable AI Inspection with 0 Defect Escape

From one golden sample to high-precision AI

We Make AI Training Easy and Sustainable

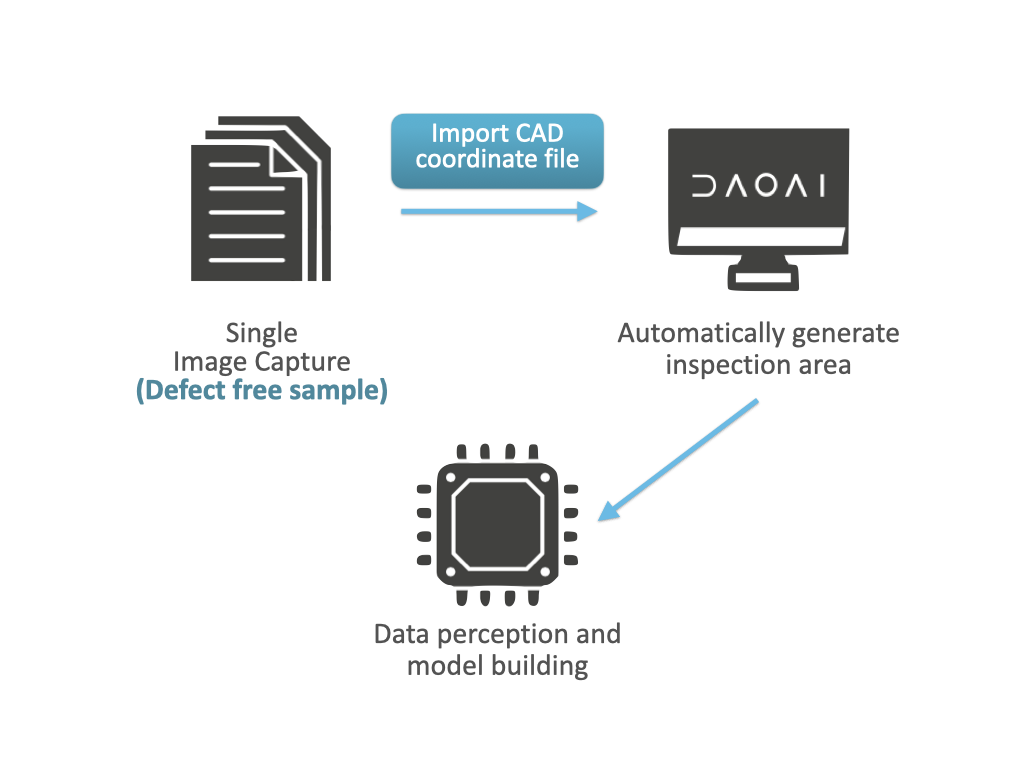

Train AI with 1 Golden Image

DaoAI‘s AI learns from defect-free images only—no need for collecting countless defective samples. Our AI is trained directly on golden samples to detect anomalies with high precision, enabling rapid and efficient deployment right on the production line.

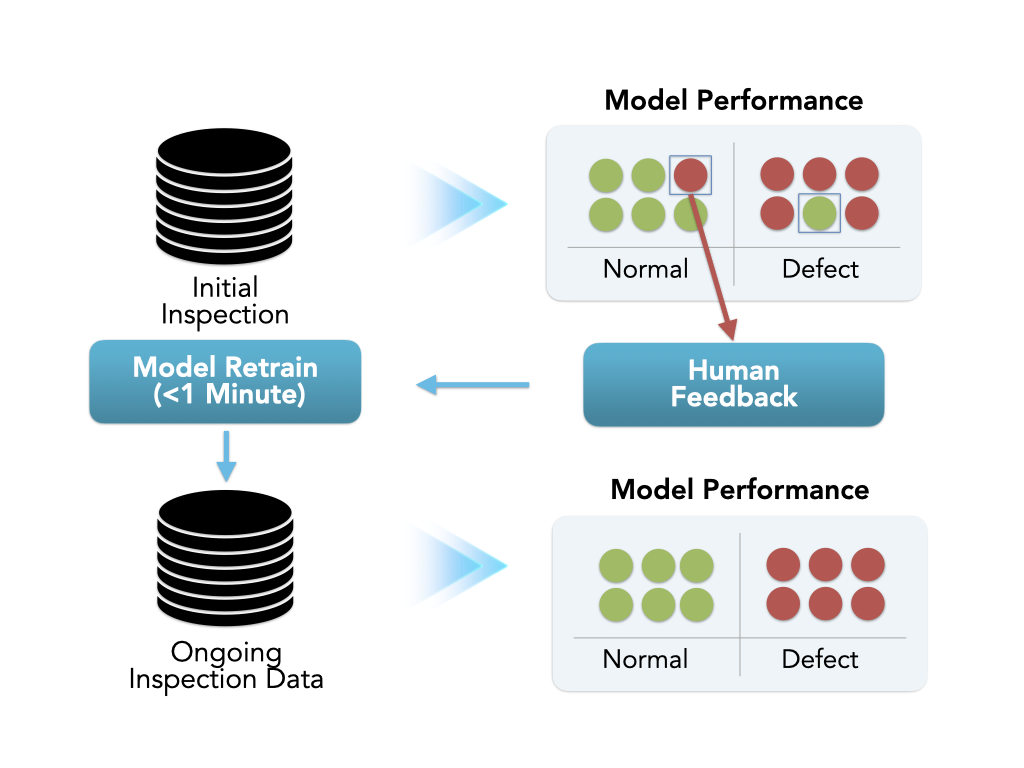

Continuous AI Model Optimization

DaoAI’s AI integrates operator feedback into its training loop, enabling real-time model updates. When defective items are flagged, on-site personnel can validate and provide corrective feedback, which the system uses to fine-tune its AI model. This dynamic learning approach ensures that detection accuracy continuously improves with production.

AI TRAINING

AI REINFORCEMENT

High-accuracy 3D Imaging Designed for PCB Inspection

Central Camera with 4-Direction Structured Light Projection

Maintains sharp focus

Accurate depth capture

Eliminates Occlusion

Uncompromised Accuracy with Telecentric Lens

Reduces perspective errors and blind spots.

Delivering actual size and shape.

Synchronized 2D + 3D Inspection

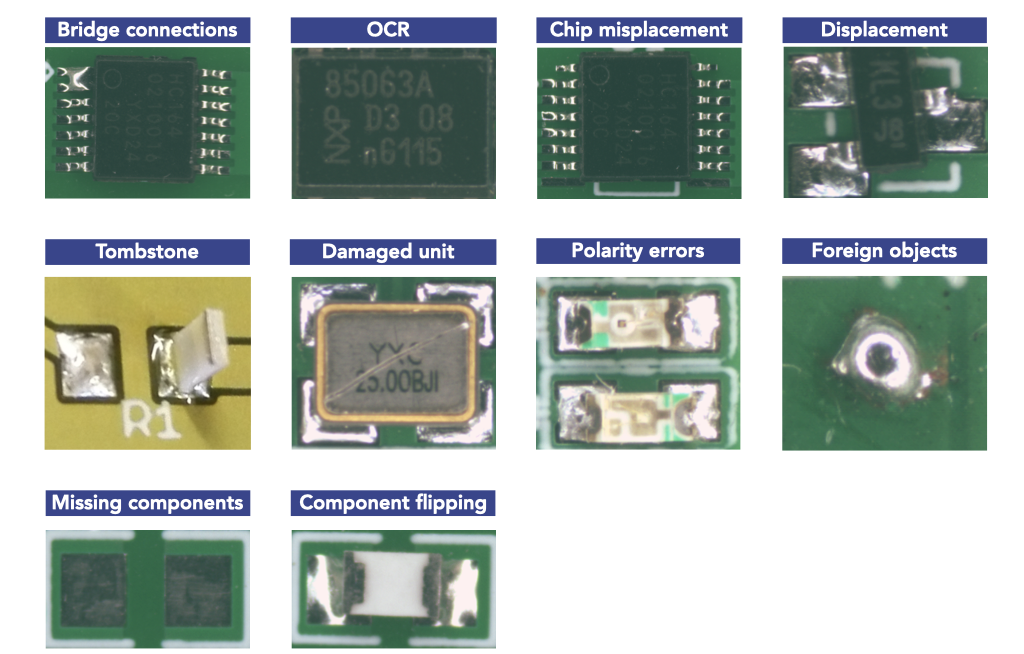

2D Full-Color Inspection Capabilities

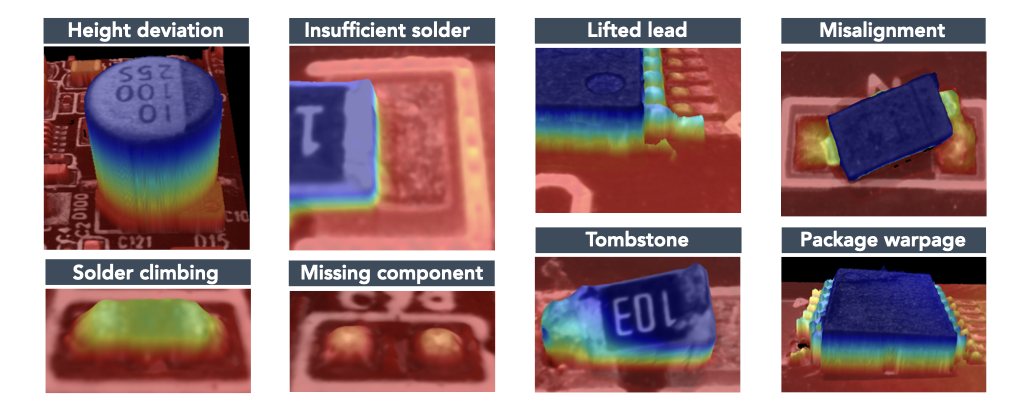

3D Inspection Capabilities

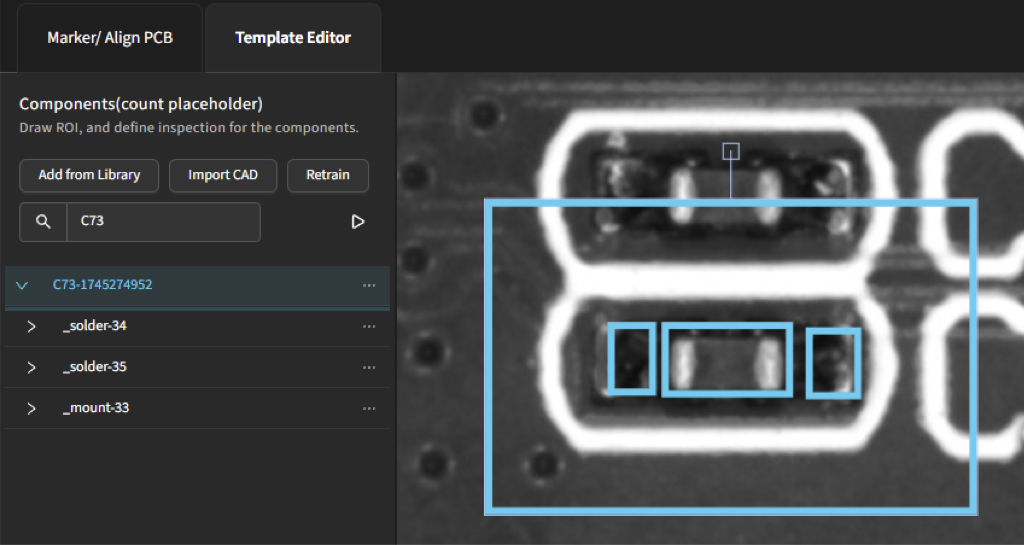

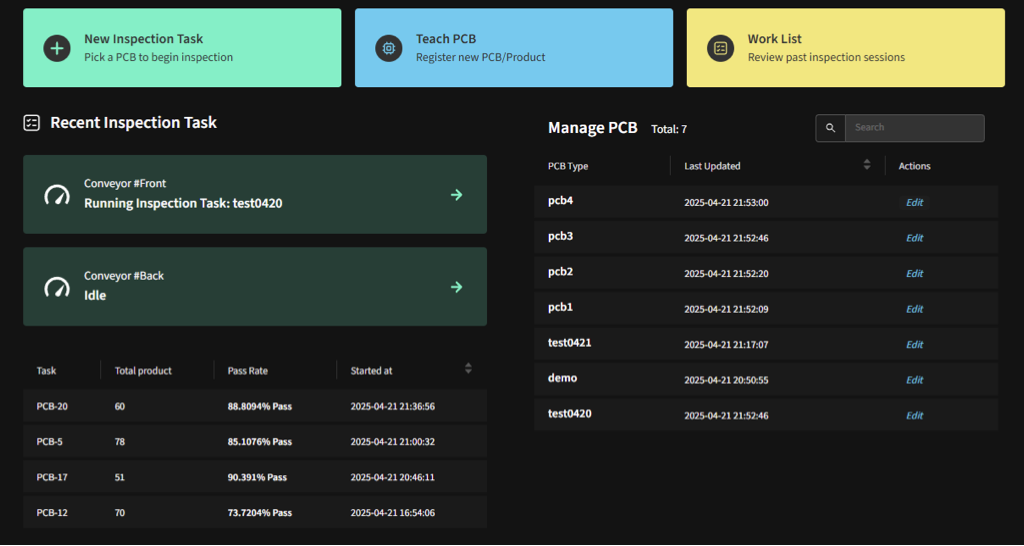

Key Software Functions

Fast Search Functionality

Quickly locate inspection records by date, serial number, or component reference designator.

Web-Based Interface

Run directly in your browser no software installation needed.

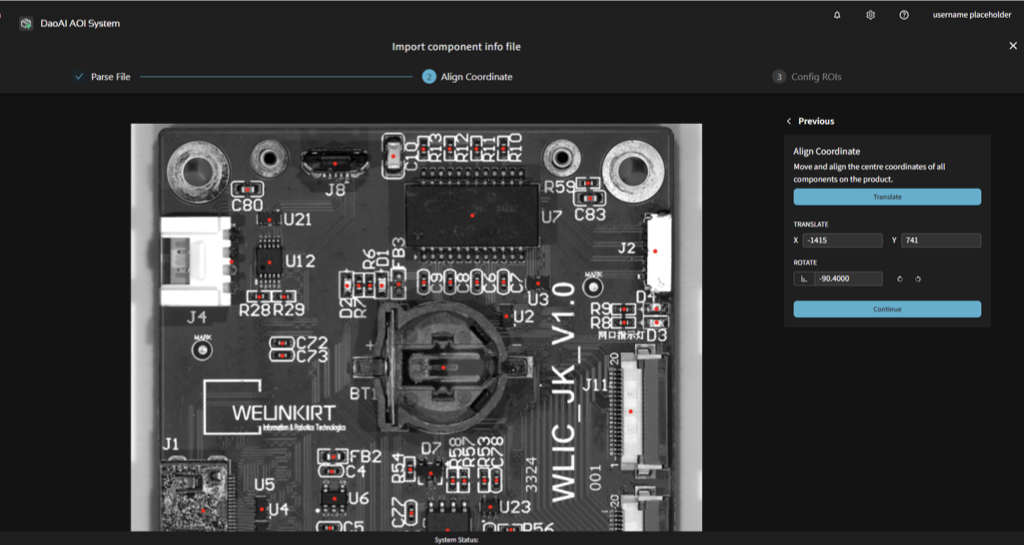

Automated Programming with Smart Template Matching

CAD Import Support

Built-In PCB Library

Automatic Template Matching

Built-In PCB Library

Automatic Template Matching

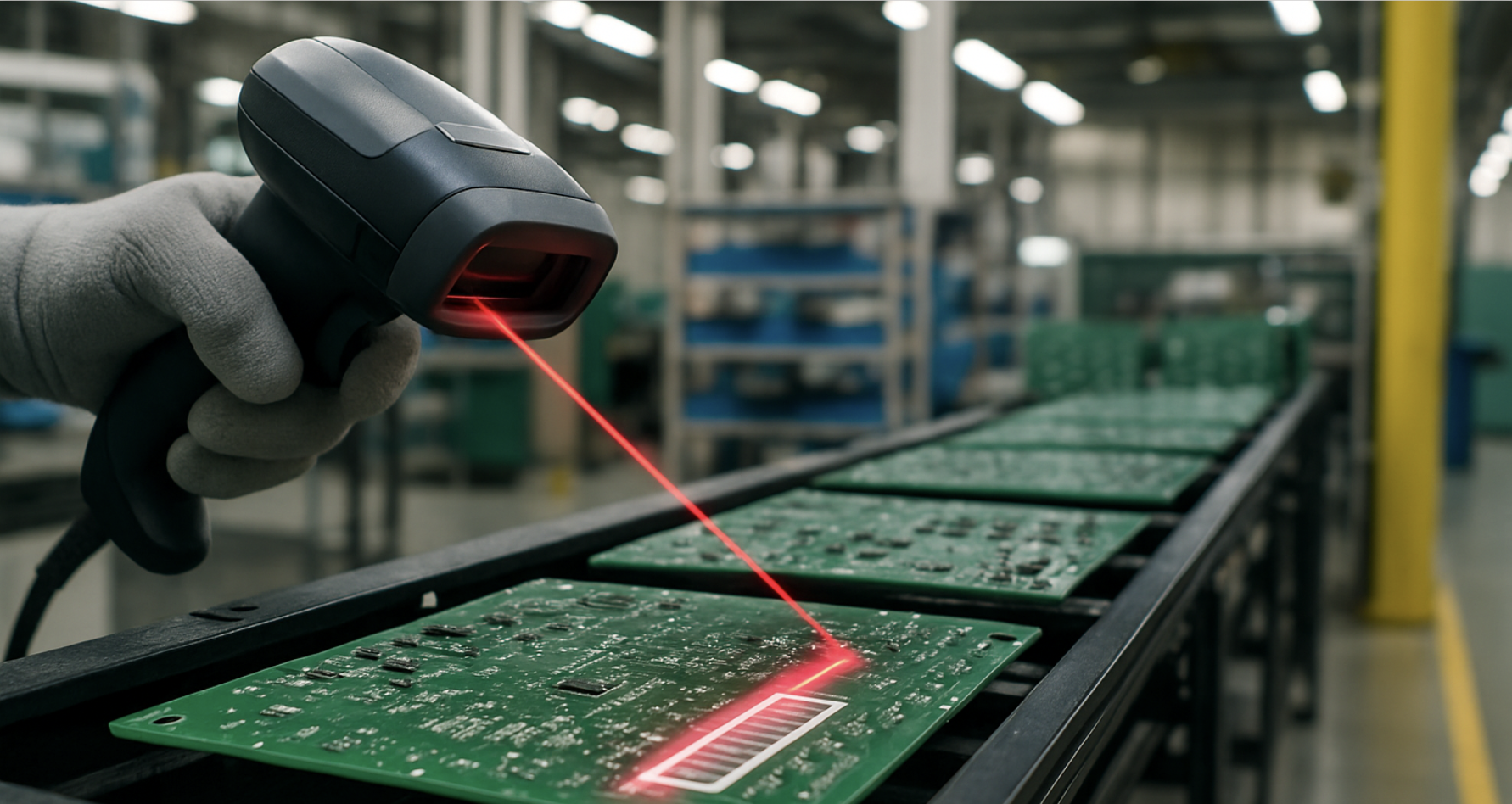

Barcode & QR Code Input

Support External Scanner Integration

MES Integration

Automatically generates MES system files to a specified directory on the AOI device.

Speed Meets Precision. Zero Compromise.

Defect Coverage

No defects go undetected

Positive Rate

Exceptional accuracy you can trust

Ultra-fast Inspection

Inspection Speed/Per Component

A Smarter & Faster AOI System with AI

DaoAI AOI System

1

Day/Learning Time

2

/ye

Billed Annually

Traditional AOI System

180

Days/Learning Time

2

/ye

Billed Annually

|

User Learning Time

|

DaoAI AOI System

1

Day/Learning Time

2

/ye

Billed Annually

|

Traditional AOI System

180

Days/Learning Time

2

/ye

Billed Annually

|

|---|---|---|

Programming Time |

10 Minutes to Get Started | Programming requires specialists and can take days or even weeks. |

Inspection Capability |

2D + 3D Synchronized Inspection | Only supports either 2D or 3D inspection. |

Training Method |

Train AI Models with a Single Golden Sample | Reply on defect sample data |

Reinforcement Mechanism |

Continuous AI Model Optimization | Complicated parameter tuning, relies heavily on operator experience |

User Interface |

Browser-Based Access – Use Anywhere, Anytime | Requires desktop software installation, local access only |

Inspection Items |

Supports exclusive golden finger detection and other inspection items including common component errors, soldering inspection, damage, and foreign objects. | Only supports selected inspection items. |

Assistance Features |

Offers our exclusive On-Site Calibration and all other support features including maintenance station, offline programming, and remote control. | None of the other systems offer the full range of features that DAOAI provides. |