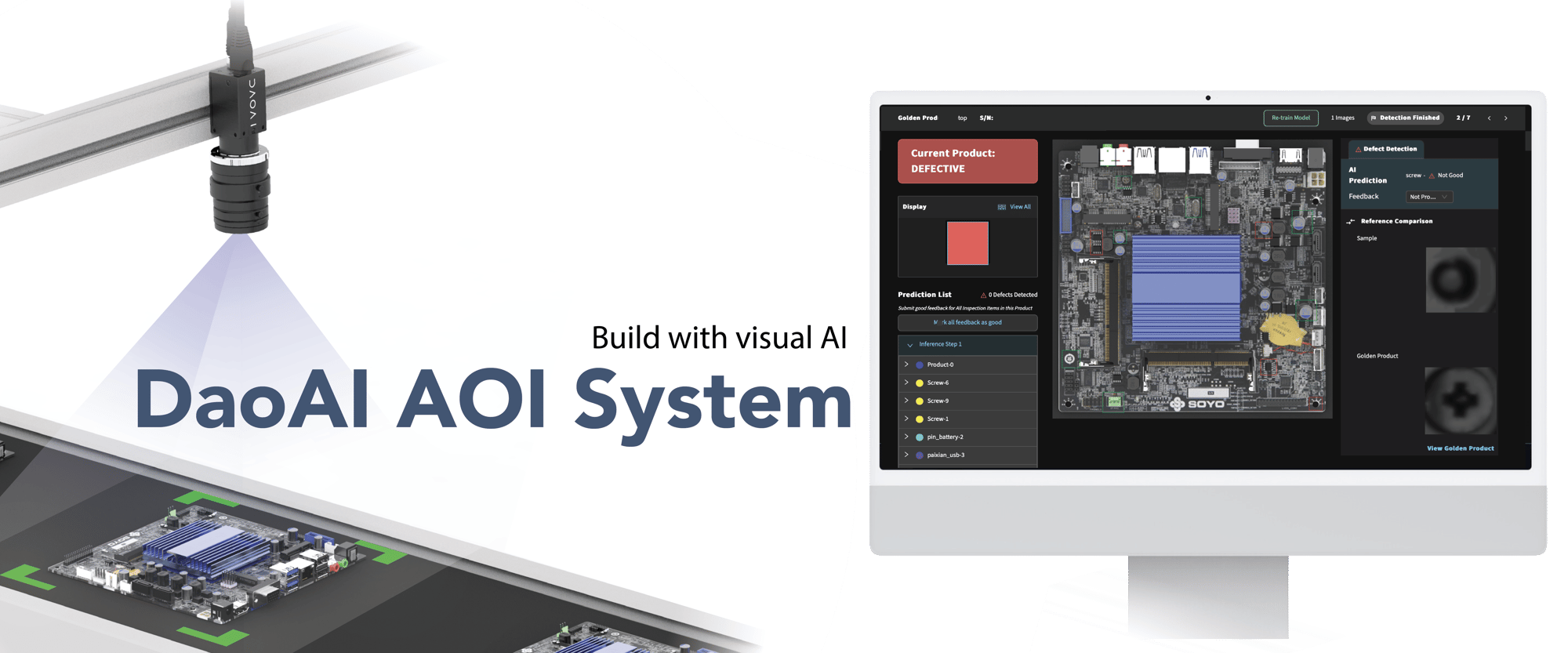

Visual AI Inspection

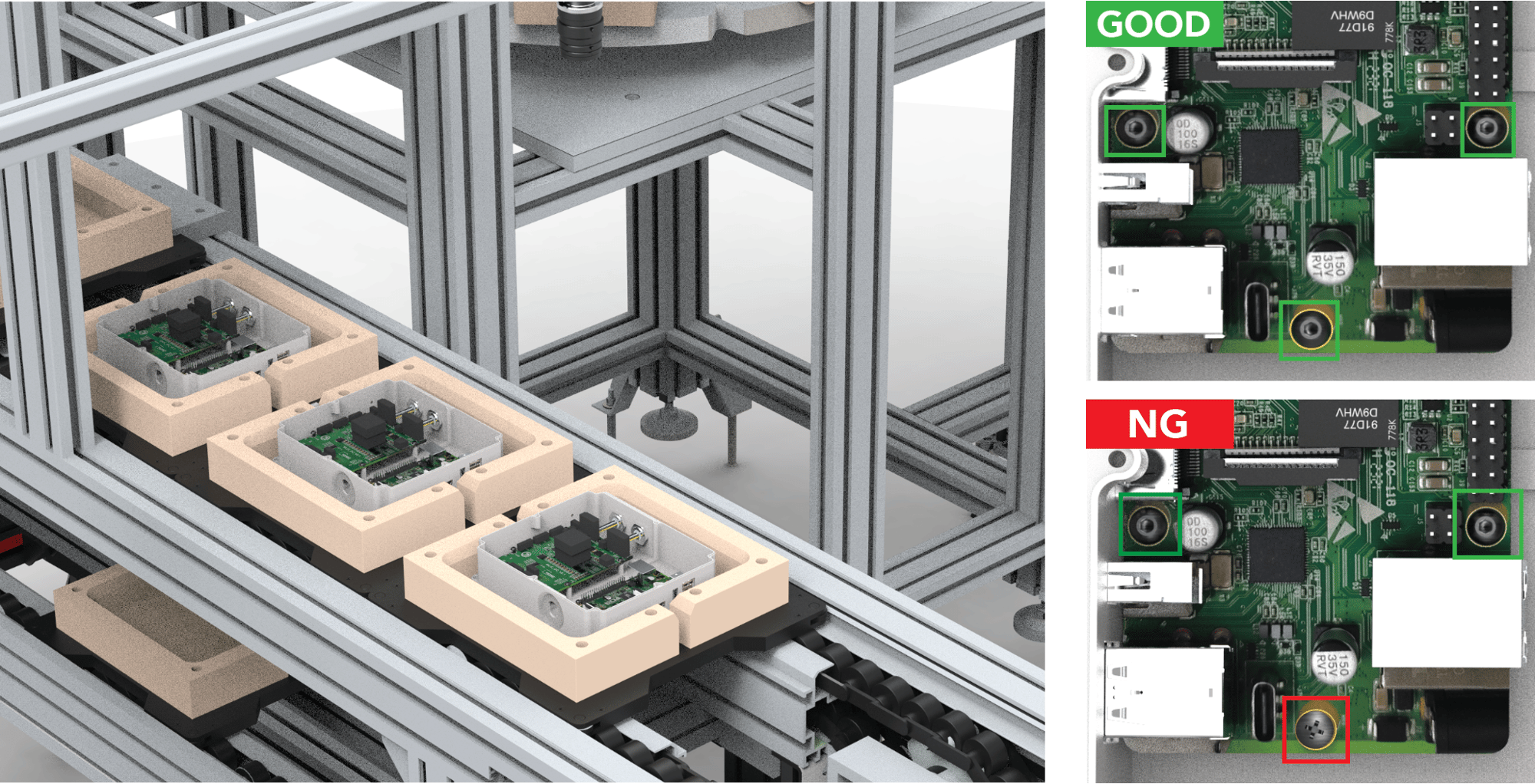

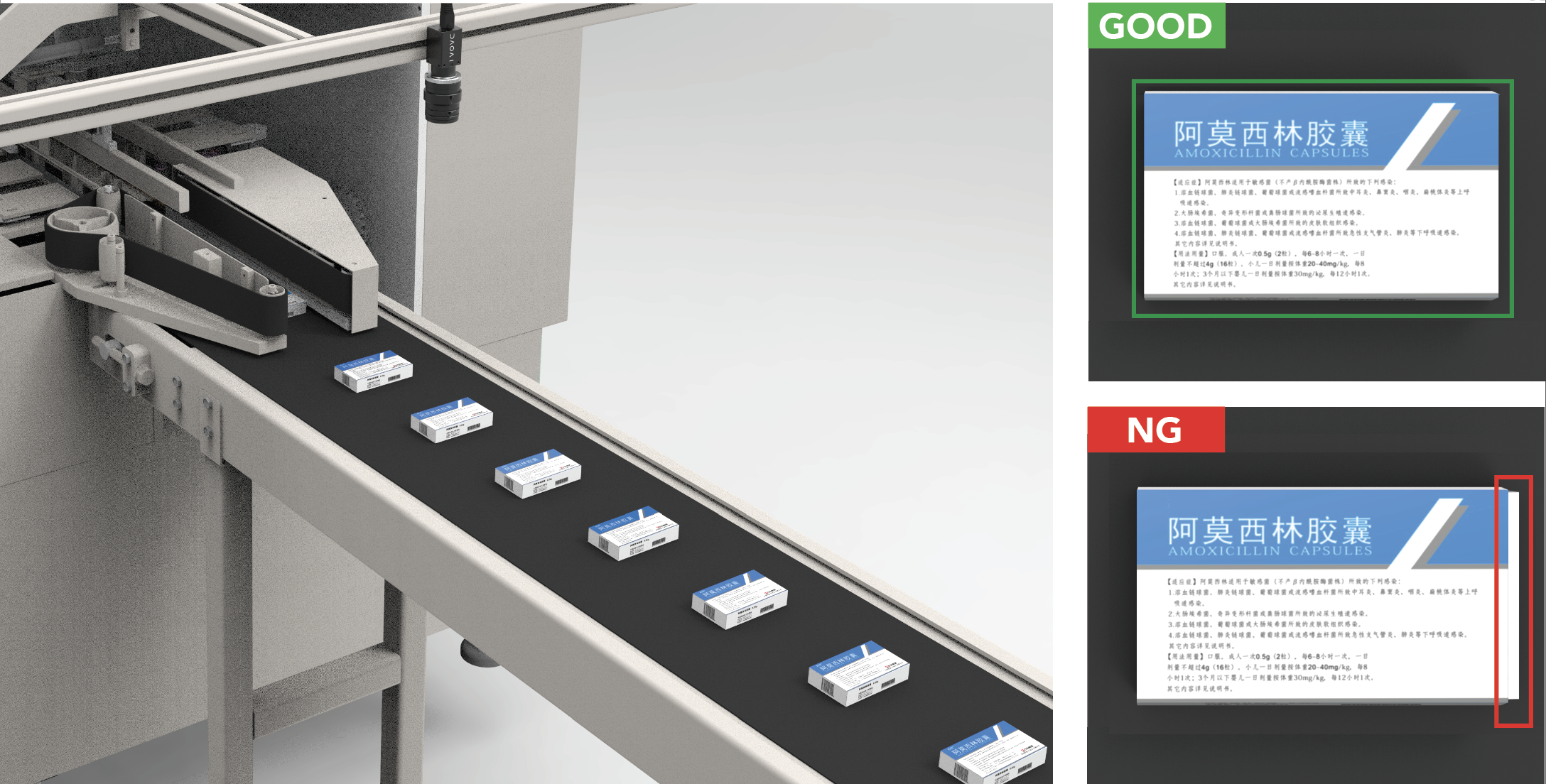

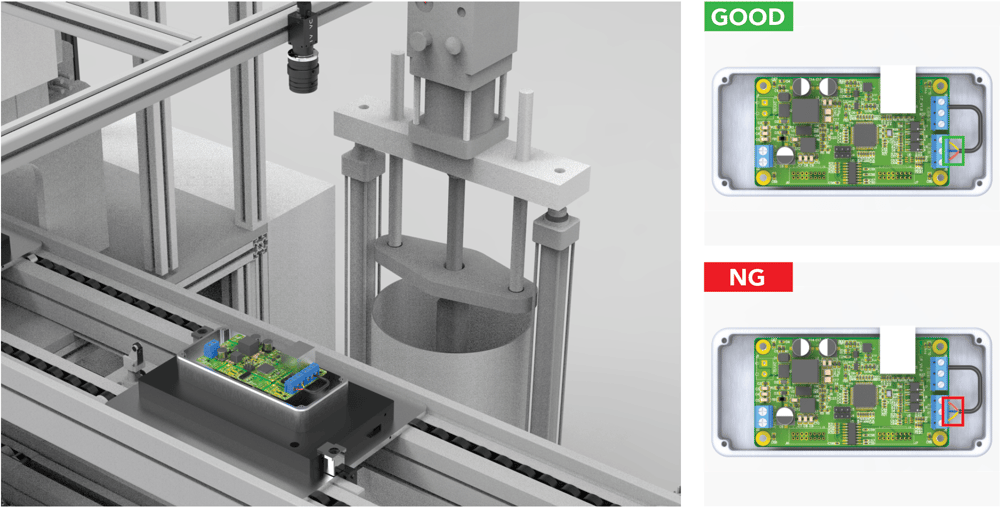

Assembly, foreign objects, and surface defects

99% +

DaoAl AOl leverages advanced Al capabilities to identify and classify defects with exceptional accuracy, significantly enhancing precision across various applications.

1 ms

Even for diverse and complex inspection tasks, AOl meets the demands of varying inspection requirements with a detection speed of 10 milliseconds per region.

4 x 4 pixel

DaoAl AOl is equipped with a powerful image optimization algorithm, capable of detecting tiny details and defects within a 4x4 pixel area, ensuring a smooth and outstanding user experience.

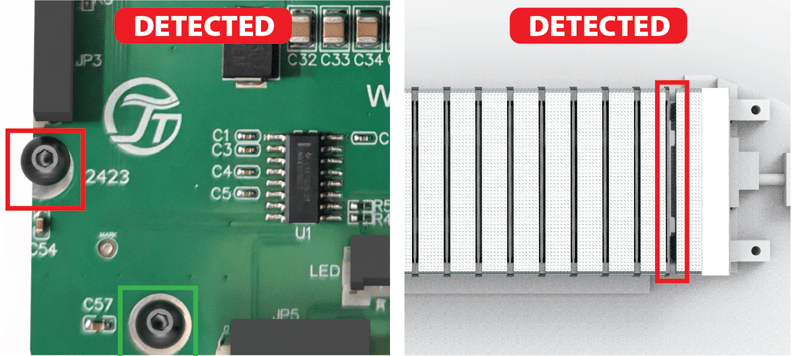

AI-BASED DEFECT INSPECTION

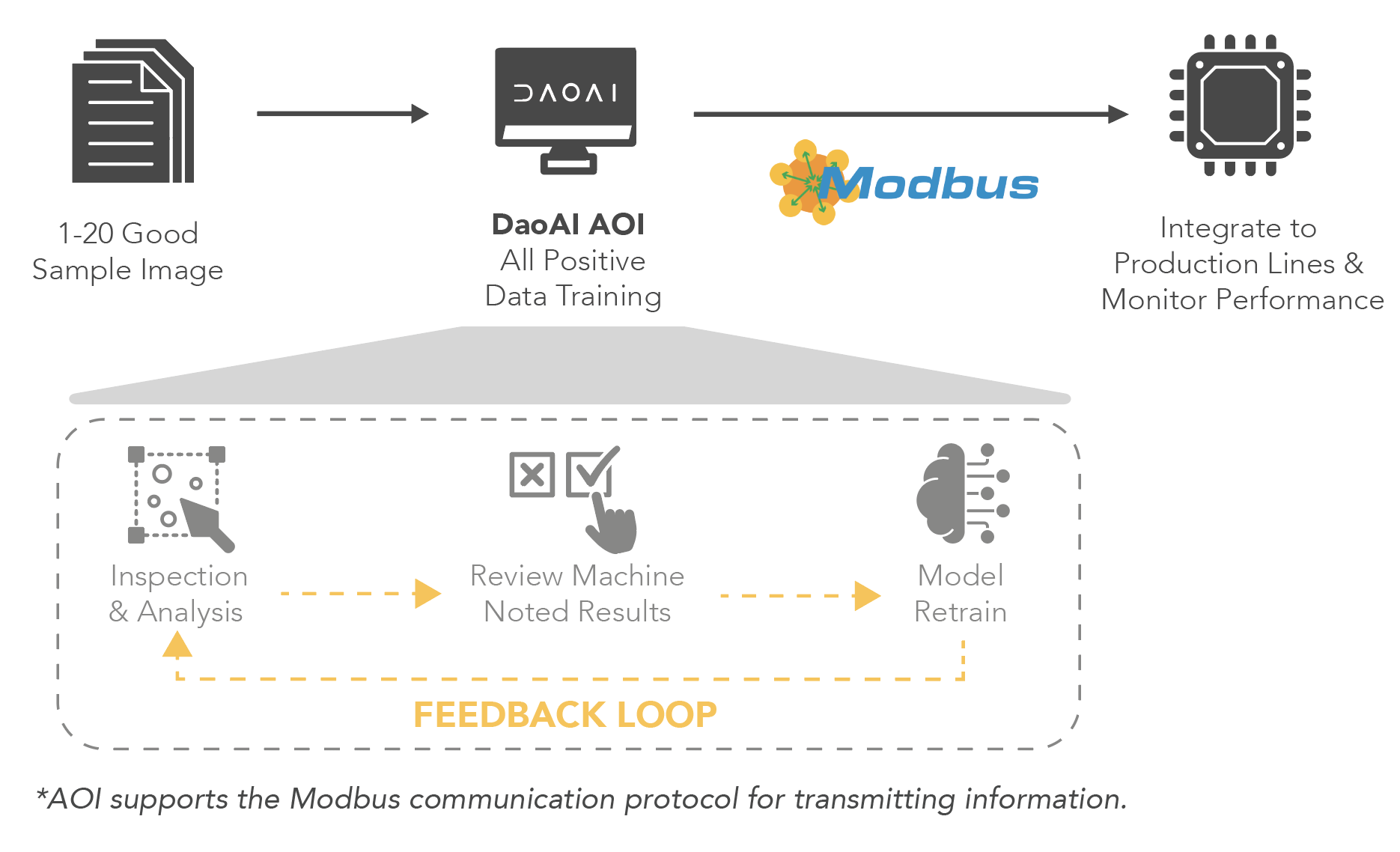

All Positive Data Training

Traditional vision systems rely on extensive datasets of both defect and non-defect images for training. In contrast, DaoAI AOI requires a single defect-free good reference images to complete the learning process and build the AI model, enabling swift and efficient on-site deployment.

|

All Positive Data Training

|

Edge AI

|

Typical Deep Learning

|

|

|---|---|---|---|

| Data Requirement | 1-20 defect-free sample image | 10-20 good and defect data | 100+ sample and defect data |

| Learning Time | 30 seconds | Several minutes | Several hours to days |

| Accuracy | High | Medium | High |

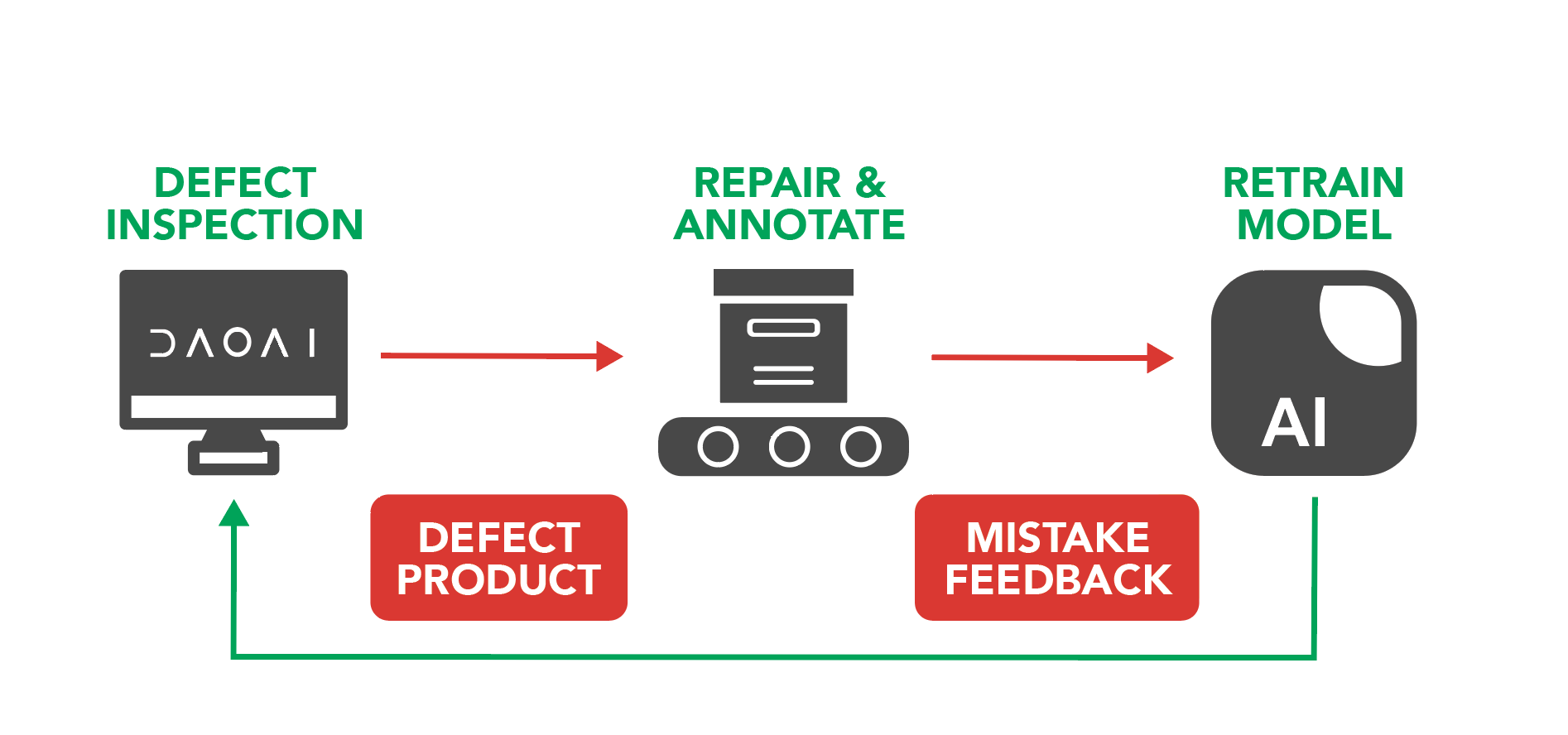

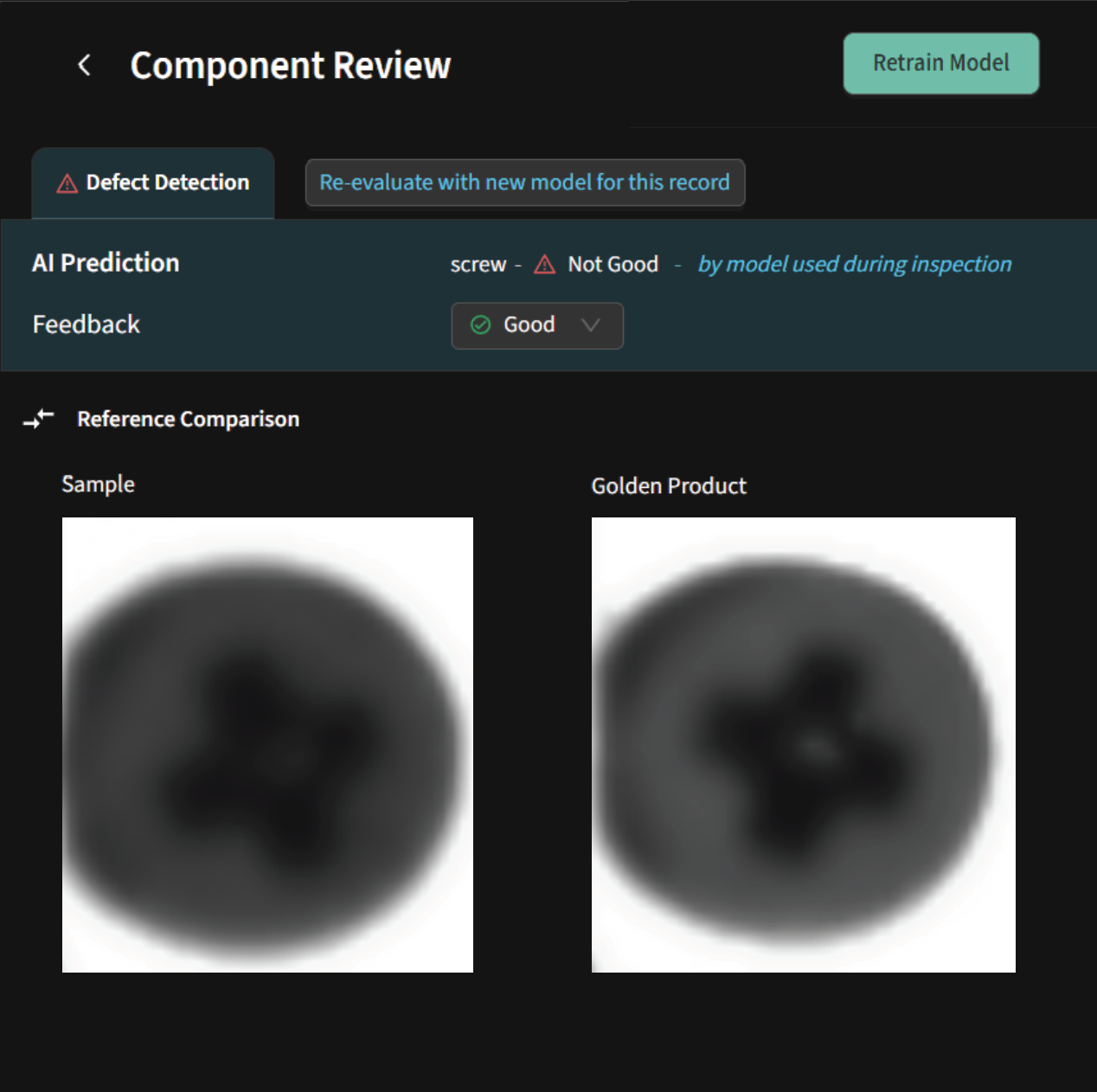

Similar to how humans learn from experience, DaoAI seamlessly integrates human feedback into its learning process. When defective products are detected on the production line, on-site personnel can review and verify them and confirm or give feedback within the system , enabling real-time model updates. This approach ensures continuous improvement in accuracy over time.

Specifically designed to

Identify complex appearance defects and challenging features

Height Detection

Ensures components like nails are properly screwed in and on correct height level. Height Detection requires using DaoAI 3D Camera.

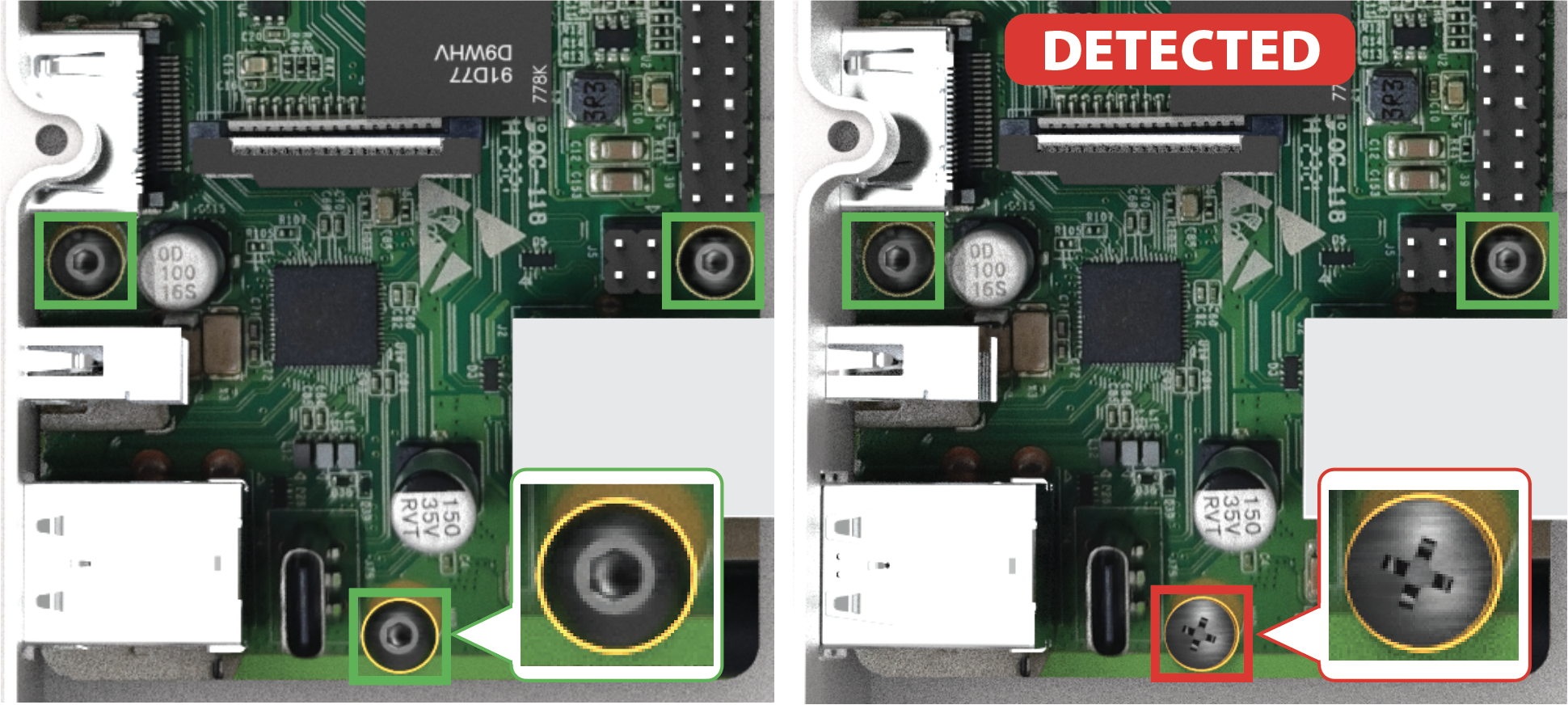

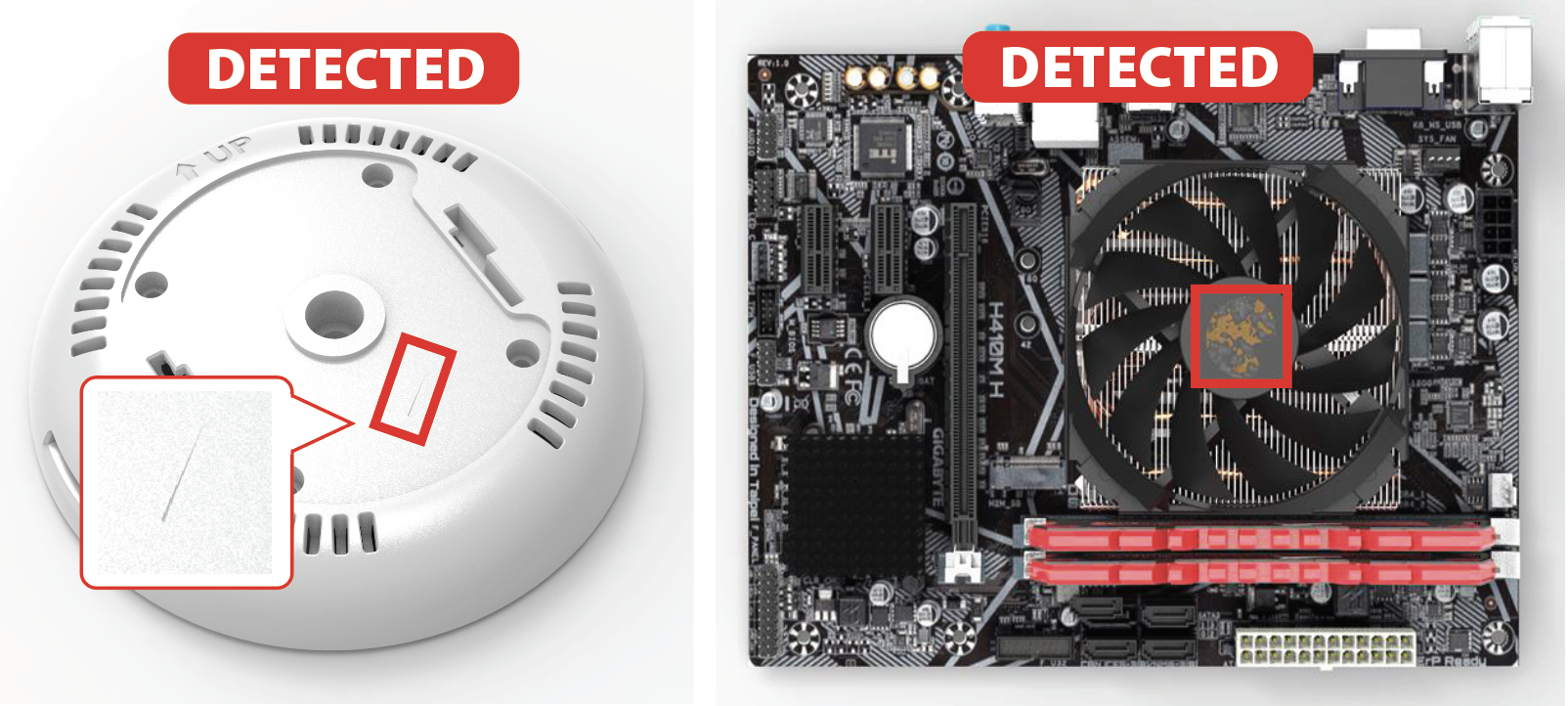

High Reflectivity Objects with Uneven Lightings

Unlike other machine vision learning systems, AOI's algorithm is capable to detect high-reflectivity objects and dark object, making it suitable for a wide range of applications.

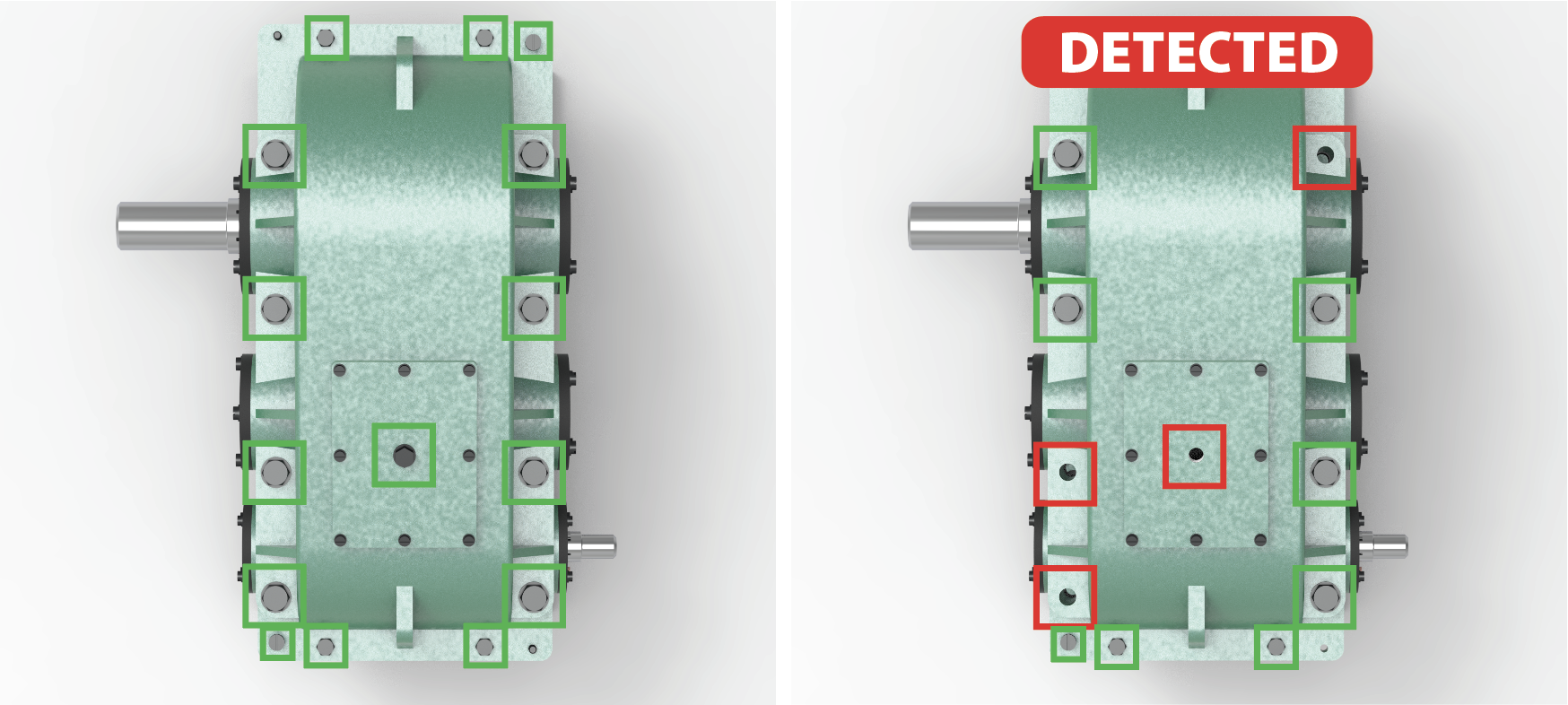

Texture Differences

Accurately distinguishes subtle variations, such as between different types of nails or screws.

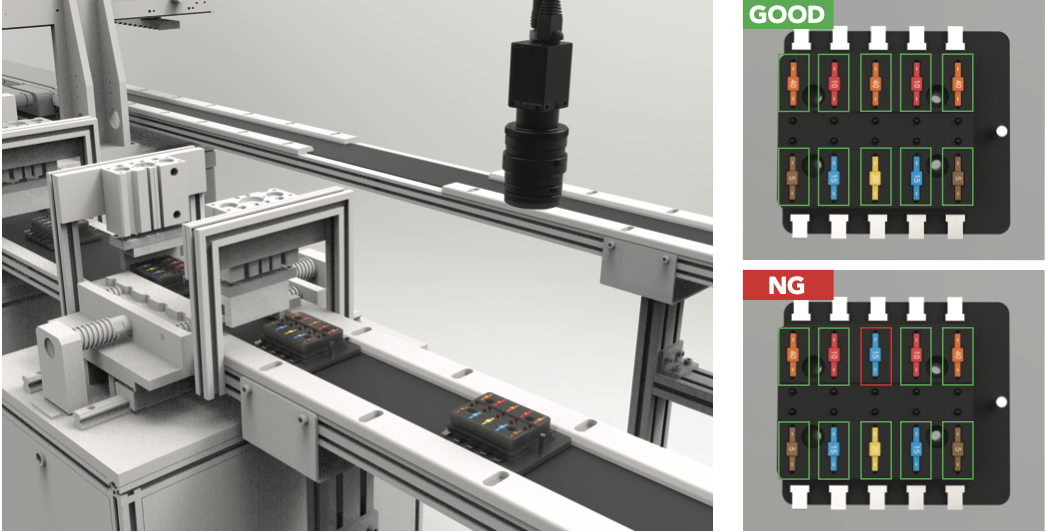

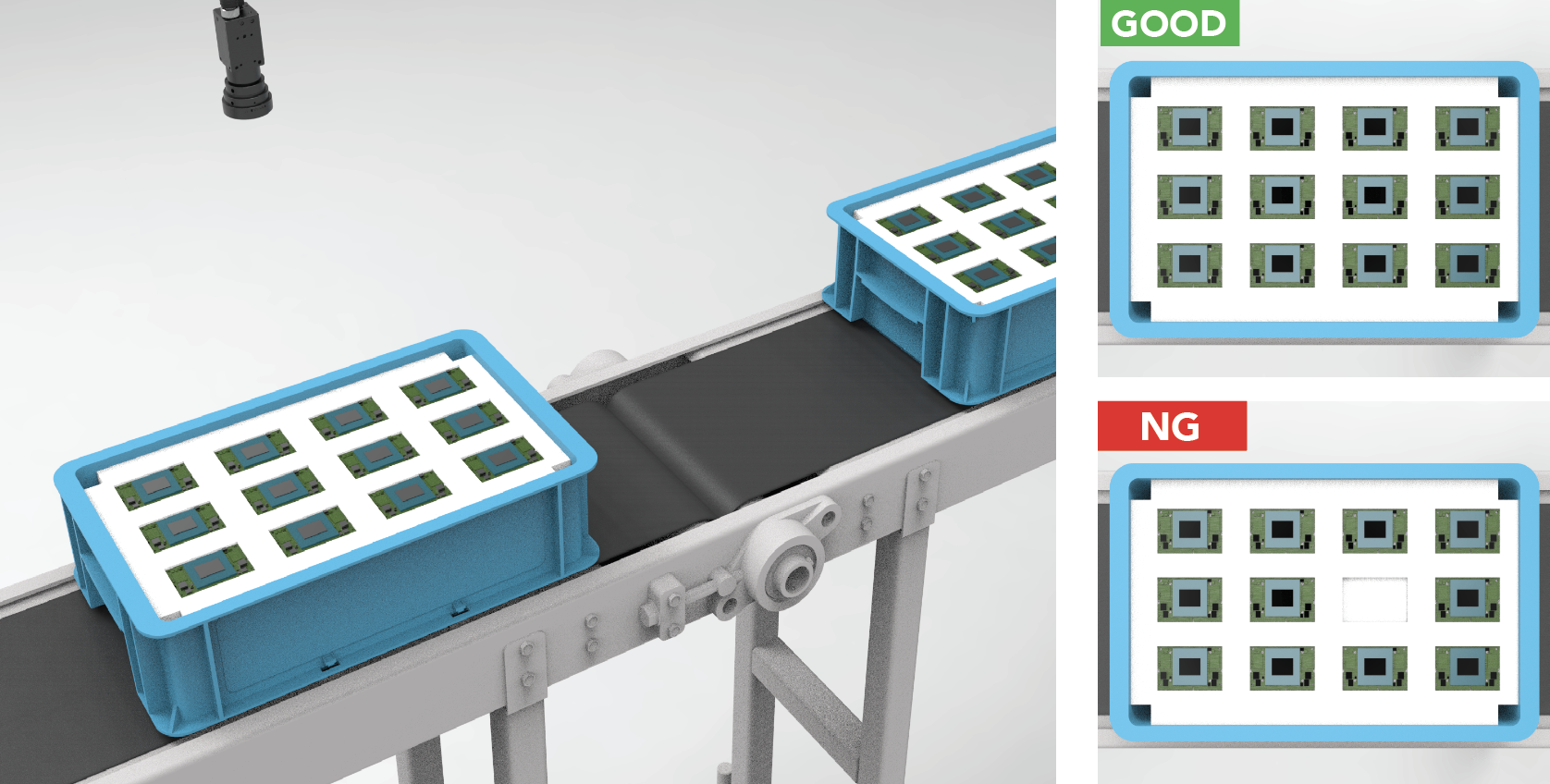

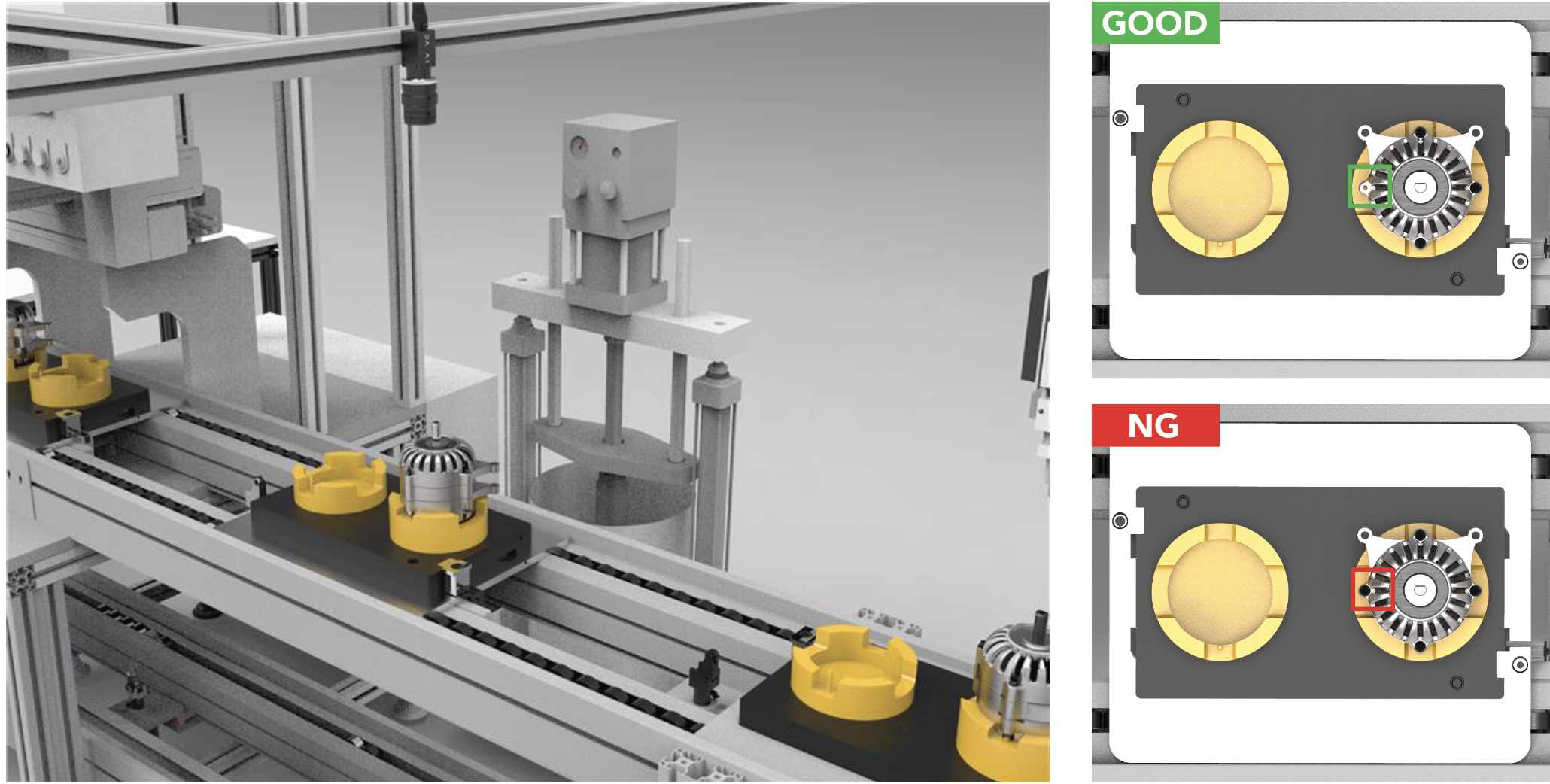

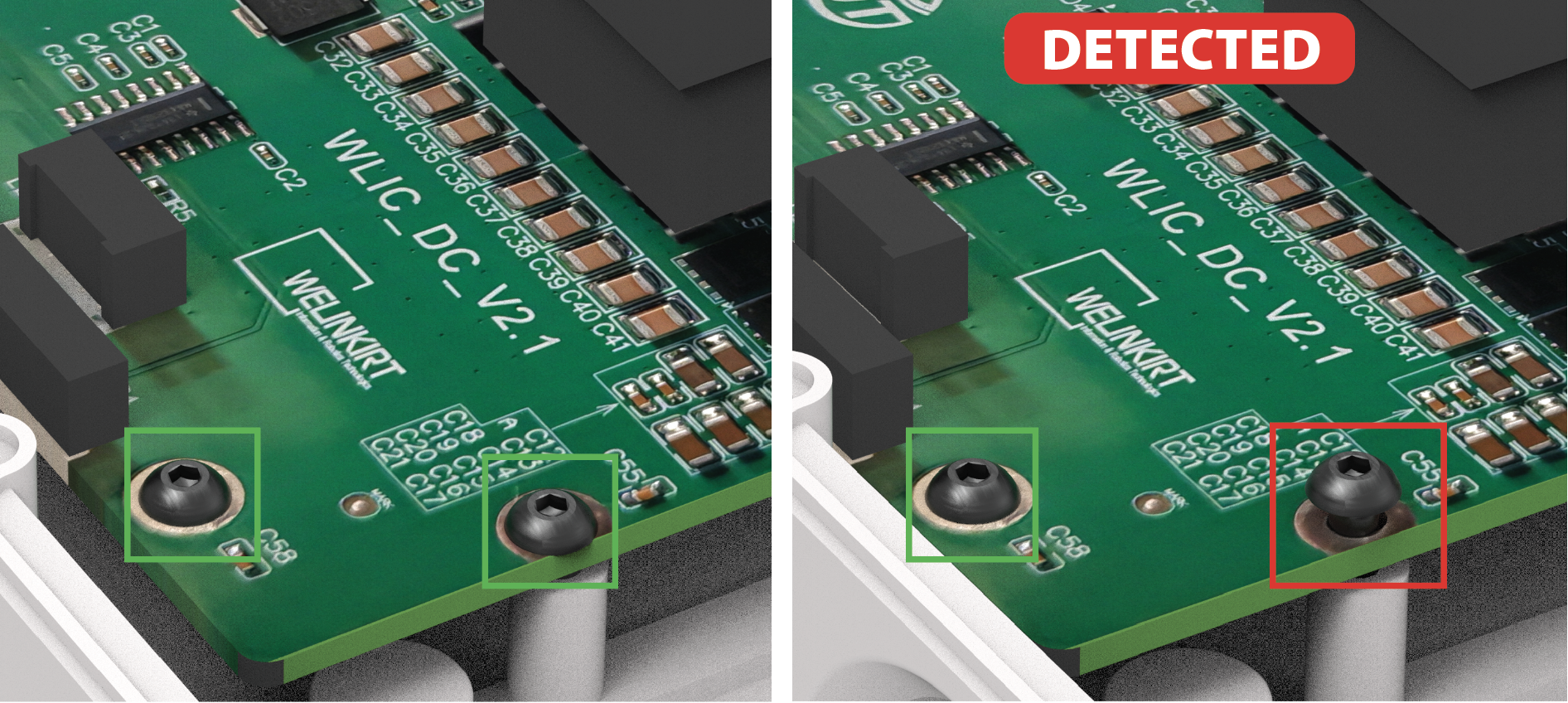

Positional Verification

Detects deviations in component sizes, misalignments, or incorrect angles.

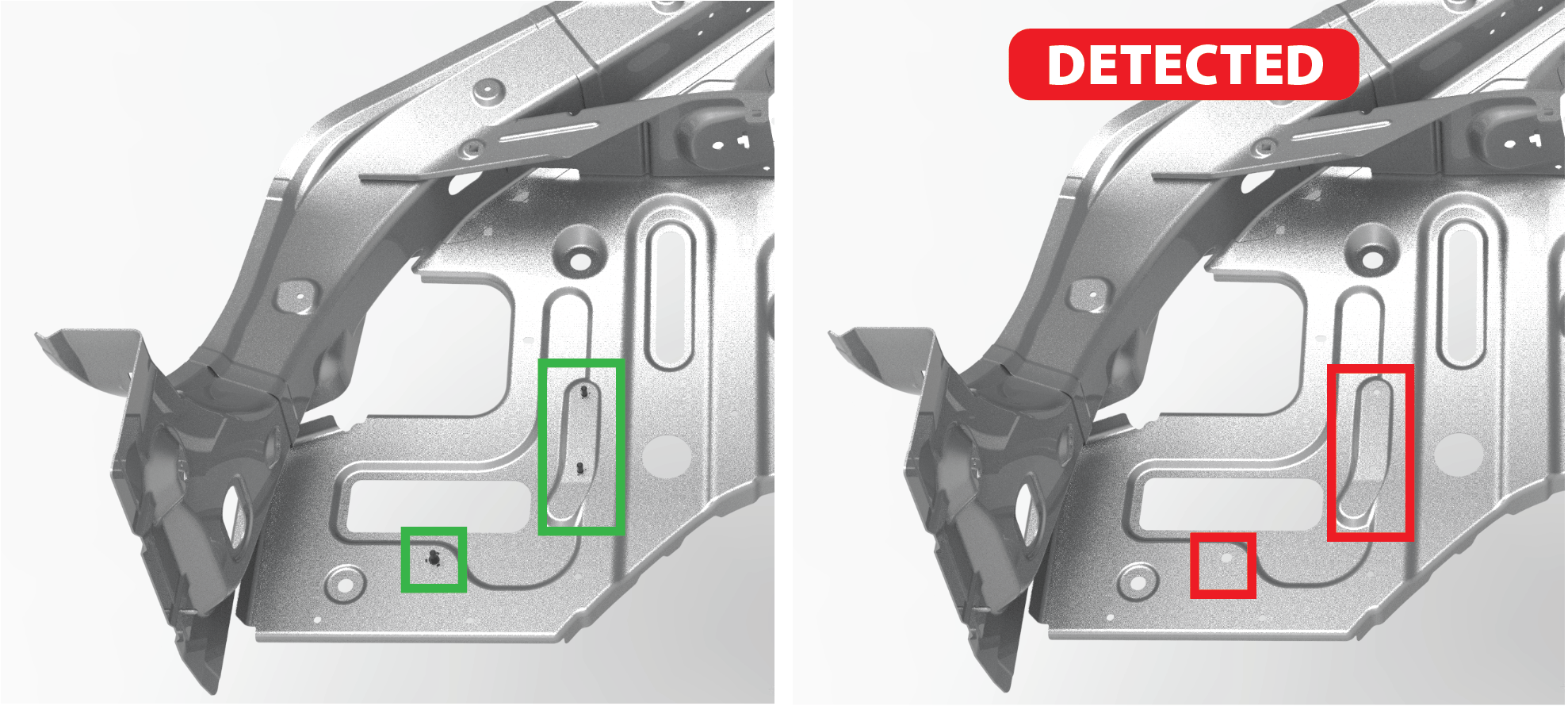

Surface Defects

Identifies dirt, dents, and other minor imperfections that may compromise quality.

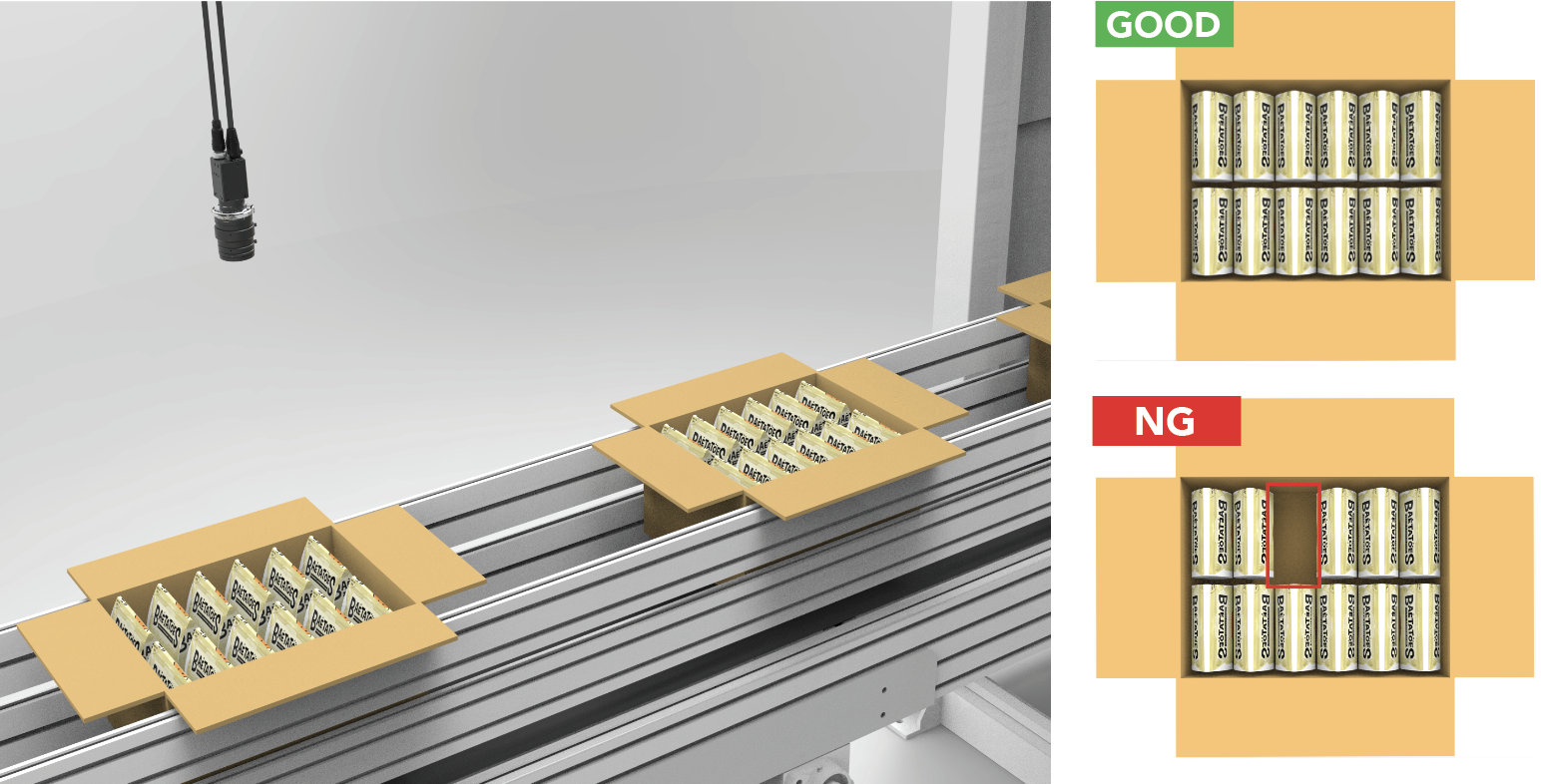

Assembly Verification

Detects deviations in component sizes, misalignments, or incorrect angles.

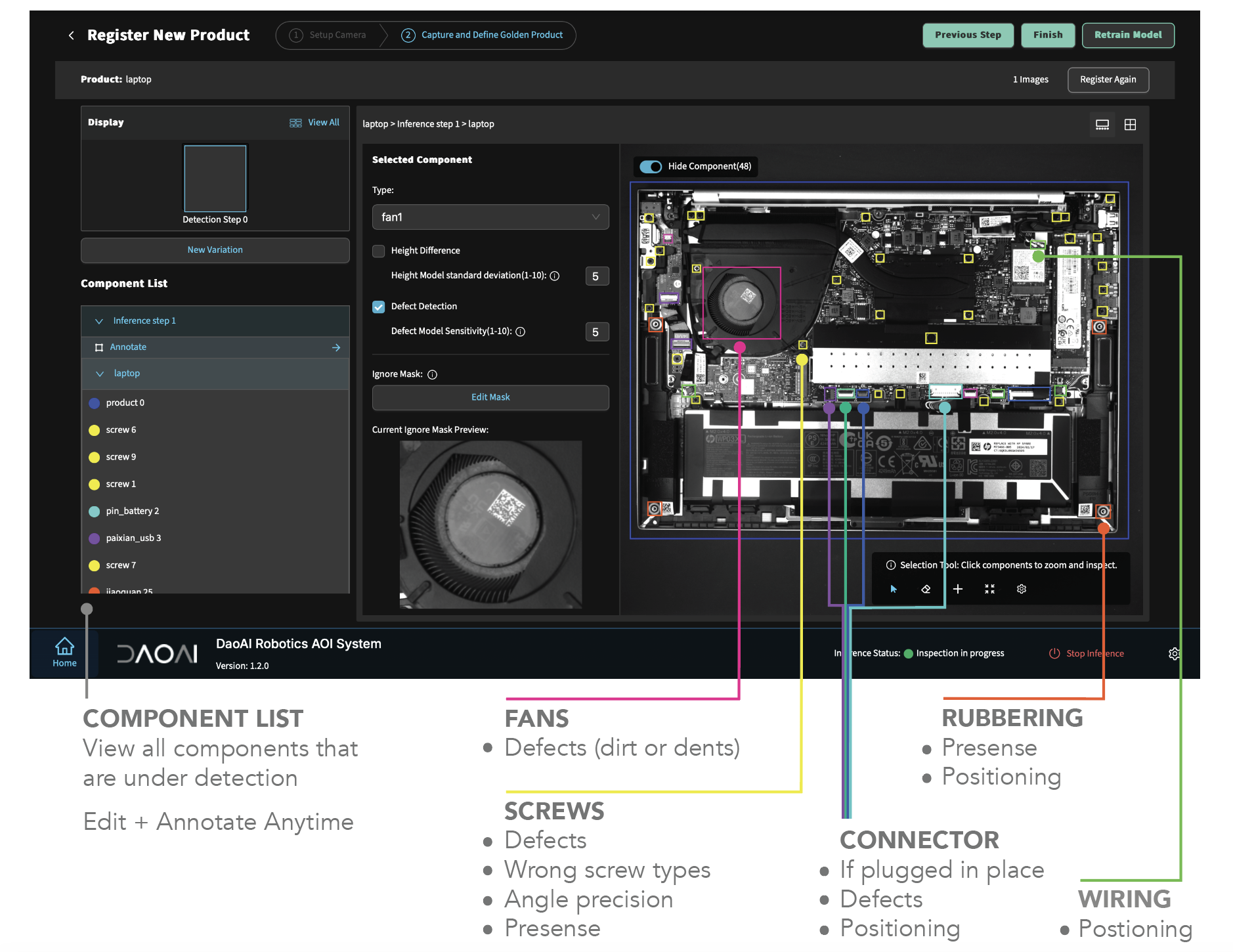

DaoAI AOI supports a wide range of component and surface identification, processing inspections on 50 different components in just 50 milliseconds. For example, soldering errors on circuit boards can be detected across hundreds of parts in mere seconds. This capability is ideal for industries like electronics manufacturing, where hundreds of components must be inspected simultaneously to identify defects such as misalignment, scratches, or plugs.

COMPONENT REVIEW

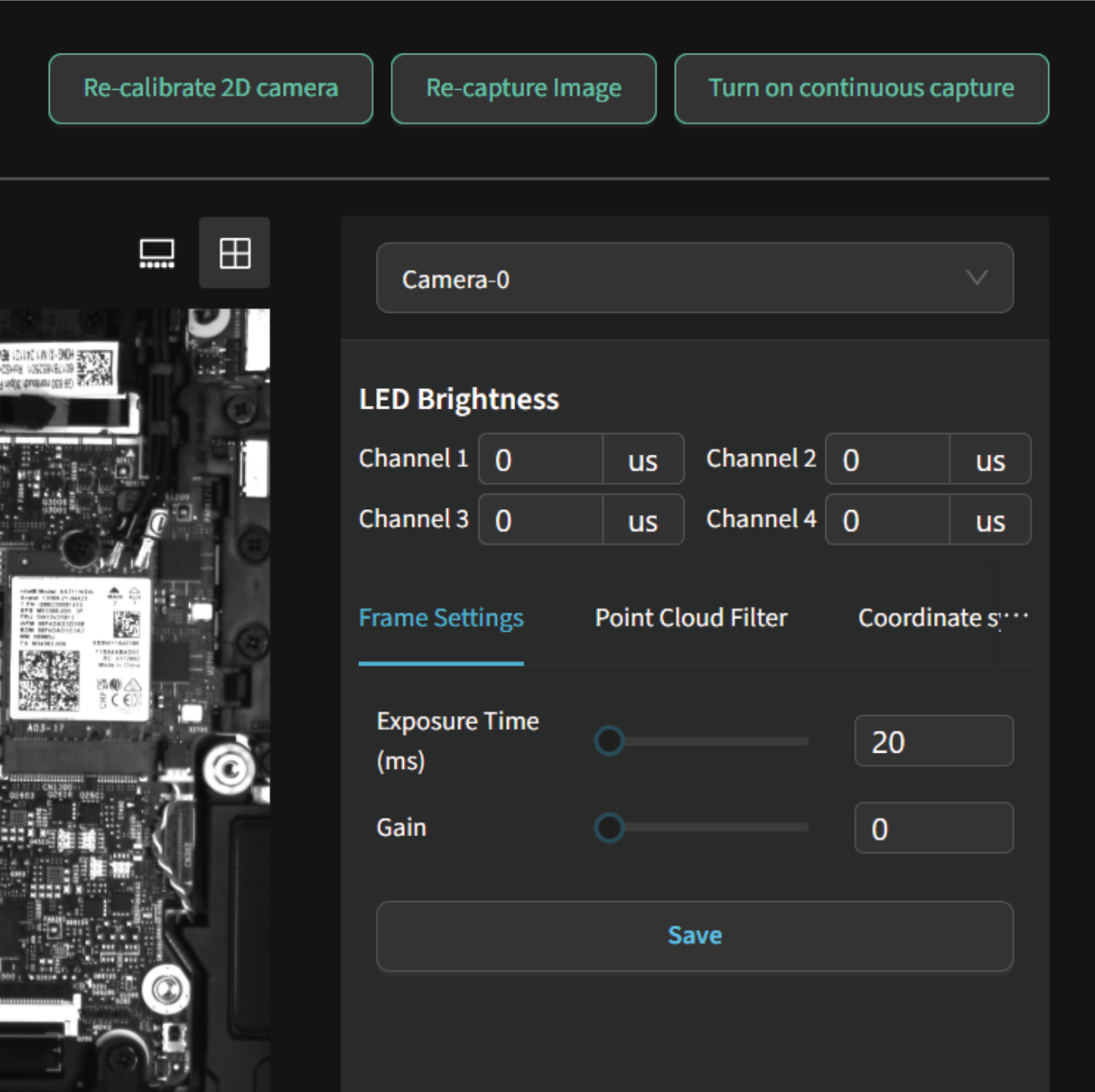

CAMERA CONFIGURATION

1 Good Sample Image to Production Line

Defect Review & Rework

-1.webp)

HARDWARE REQUIREMENTS

Recommended PC Spec:

|

Capability |

GPU |

CPU |

Storage |

RAM |

|

2D |

NVIDIA 3060 |

Intel 10500K |

1TB |

32GB |

|

3D |

NVIDIA 4080 |

Intel 10500K |

1TB |

32GB |

Minimum PC Spec:

|

Capability |

GPU |

CPU |

Storage |

RAM |

|

2D |

NVIDIA1050ti |

Intel 10500K |

256GB |

16GB |

|

3D |

NVIDIA 3060 |

Intel 10500K |

256GB |

16GB |

Camera & Interface

DaoAI AOI supports most 2D machine vision cameras available on the market. We support USB 3.0 and GigE interfaces to ensure optimal stability in industrial applications.

AD-080

- Central camera with dual projectors ensures precise focus and measurement.

- Dual illumination provides uniform lighting and eliminates distortion.

- 18MP camera with 3D HDR captures black and reflective surfaces clearly.

- Independent controlled 2D/3D measurement modes with 10GigE transmission.

- Quick recalibration after vibrations or environmental shifts.

- 77×70mm FOV with 4μm repeatability for small component inspection.

AD-470

- Central camera with dual projectors ensures precise focus and measurement.

- Dual illumination provides uniform lighting and eliminates distortion.

- 18MP camera with 3D HDR captures black and reflective surfaces clearly.

- Independent controlled 2D/3D measurement modes with 10GigE transmission.

- Quick recalibration after vibrations or environmental shifts.

- 477×435mm FOV with 40μm precision for laptop-sized objects.

AQ-060

- Central camera with quad-directional projection for precise, focused imaging.

- Four-way lighting prevents shadows and reflections for complete coverage.

- 18MP camera with telecentric lens reduces distortion and eliminates blind spots.

- 1-second 3D reconstruction with 60×60mm FOV, ideal for PCB inspection.

- Supports 3D and 2D measurements, as well as RGB 2D imaging.

- Quick recalibration after vibrations or environmental shifts.

- CXP interface provides 10× faster data transfer than USB 3.0.

APPLICATIONS