DaoAI PCBA AOI

AI Inspection System

Program, detect, improve, all with AI.

Program faster, detect smarter, and improve continuously

99% Accuracy with AI Algorithms

No Overkill, No Missed Defects

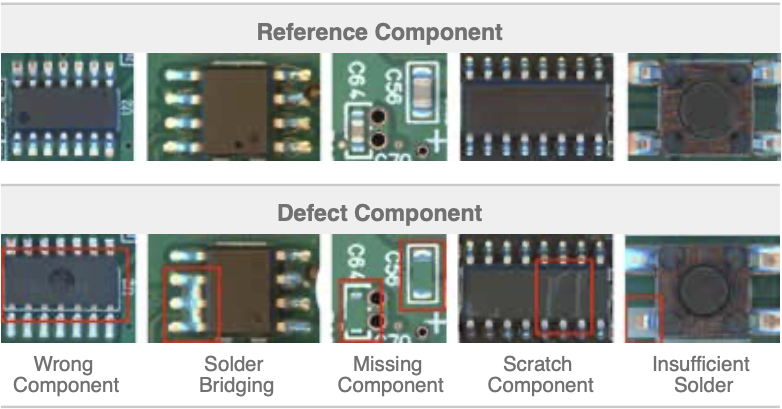

Compared with rule-based or grayscale rule algorithms, Visual AI overcomes missed detections caused by similar colors between the PCB and components. It significantly improves detection accuracy for defects such as missing parts and scratches.

Accurately recognize text on components

PCB Dedicated OCR

AI training are based on real PCBA photos, and it overcomes challenges like blur, damage, dirt, and low contrast

1 ms /component

Millisecond-level Inspection

Instantly detects missing parts, wrong components, and polarity on high-density boards without computing bottlenecks.

CPU/GPU Parallel Processing Architecture

GPU focuses on processing complex defects and OCR, while the CPU synchronously handles logic operations. True parallel processing ensures tasks do not wait for each other, maximizing hardware efficiency.

45 cm²/s

High Throughput

Perfectly matches the rhythm of high-speed SMT lines, eliminating post-reflow inspection bottlenecks.

Complete Modeling in 5 Minutes

No CAD or libraries — one golden sample covers capacitors, resistors, IC pins, and all defect types.

AI Auto-Detects Components and Generates Bounding Boxes

With no coordinate data required, AI automatically maps every component and creates precise bounding boxes within seconds, even for rotated parts, significantly shortening initial programming time.

AI-Generated Inspection Thresholds

AI analyzes the golden sample’s color distribution and automatically generates optimal thresholds, greatly reducing debugging time and speeding up recipe completion.

Smarter and more stable the longer it runs.

Operators can instantly provide feedback to retrain the AI model in real-time. With every new batch of production data, the system continuously improves.

Iterative Learning Loop

Reduces False Alarms Through Feedback Learning

When an operator confirms a false alarm, the AI learns the true characteristics as training samples, preventing similar features from being misjudged again and progressively reducing false alarms.

Offline 2D AI AOI Machine

DaoAI P1 & P2

DaoAI P1& P2 leverages advanced visual AI to automate PCBA inspection programming. By learning directly from golden sample, it auto-detects components, generates bounding boxes, and defines defect thresholds — accelerating setup from hours to 5 minutes.

Introducing DaoAI P Series

Offline & Inline 2D AI AOI Solutions

DaoAI offline and inline 2D AI AOI machines leverage advanced visual AI to automate PCBA inspection programming. By learning directly from golden sample, it auto-detects components, generates bounding boxes, and defines defect thresholds — accelerating setup from hours to 5 minutes.

DaoAI P1/P2 Specifications

DaoAI P1

5MP0 Camera /month

DaoAI P2

12MP0 Camera /month

DaoAI P1

DaoAI P2

Optical System

Conveyor & PCB Size

Inspection Capability

Additional Functions

Inspection and Auto-Configuration Capabilities

|

Body |

Polarity | IC Leads |

Text

|

|

|---|---|---|---|---|

|

Capacitor |

|

|

|

|

|

Resistor |

|

|

|

|

|

Multilayer Chip Inductor |

|

|

||

|

Aluminum Electrolytic Capacitor |

|

|

|

|

|

Tantalum Capacitor |

|

|

|

|

|

Resistor Array |

|

|

|

|

|

Power Inductor |

|

|

||

|

LED |

|

|

|

|

|

SOT/SOD |

|

|

|

|

|

SOIC/SOP/TSOP/TSSOP/MSOP |

|

|

|

|

|

QFP |

|

|

|

|

|

QFN |

|

|

||

|

TO-263/TO-252 |

|

|

Subscribe to our Newsletter!

Are you interested in being notified when we publish the feature or applications? Sign up now to stay in the loop.