DaoAI World

Build Custom Visual AI Models — No Coding Needed

-1.png)

Leveraging the latest AI technology with 9 models. DaoAI World delivers powerful AI-driven machine vision tools directly to your fingertips. It achieves an "all-in-one learning" approach, minimizing human efforts in maintain system learning.

Enable inspections from basic to advanced

Well-Tuned AI Models

DaoAI World provides 11 fine-tuned AI models that have been verified across tons of real-world in-field applications, offering numerous advantages, including accelerated development, reduced costs, and improved performance.

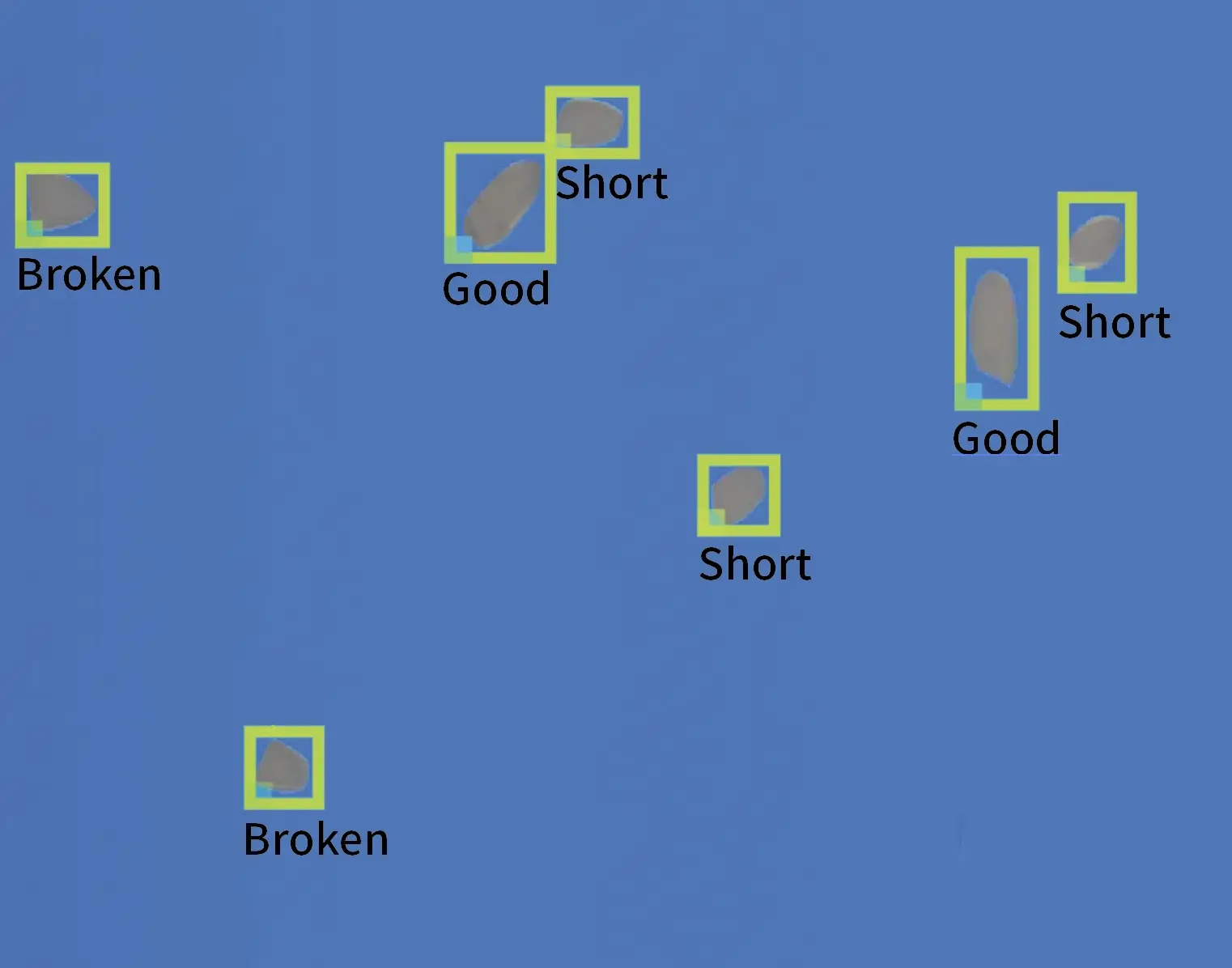

Hybrid Model

Enables simultaneous object detection and classification, providing a more holistic approach to visual analysis and supporting multi-task execution.

Rotated Object Detection

Accurately detects objects and their orientation in images, supporting rotated rectangles and flexible-shaped bounding boxes for precise alignment and analysis.

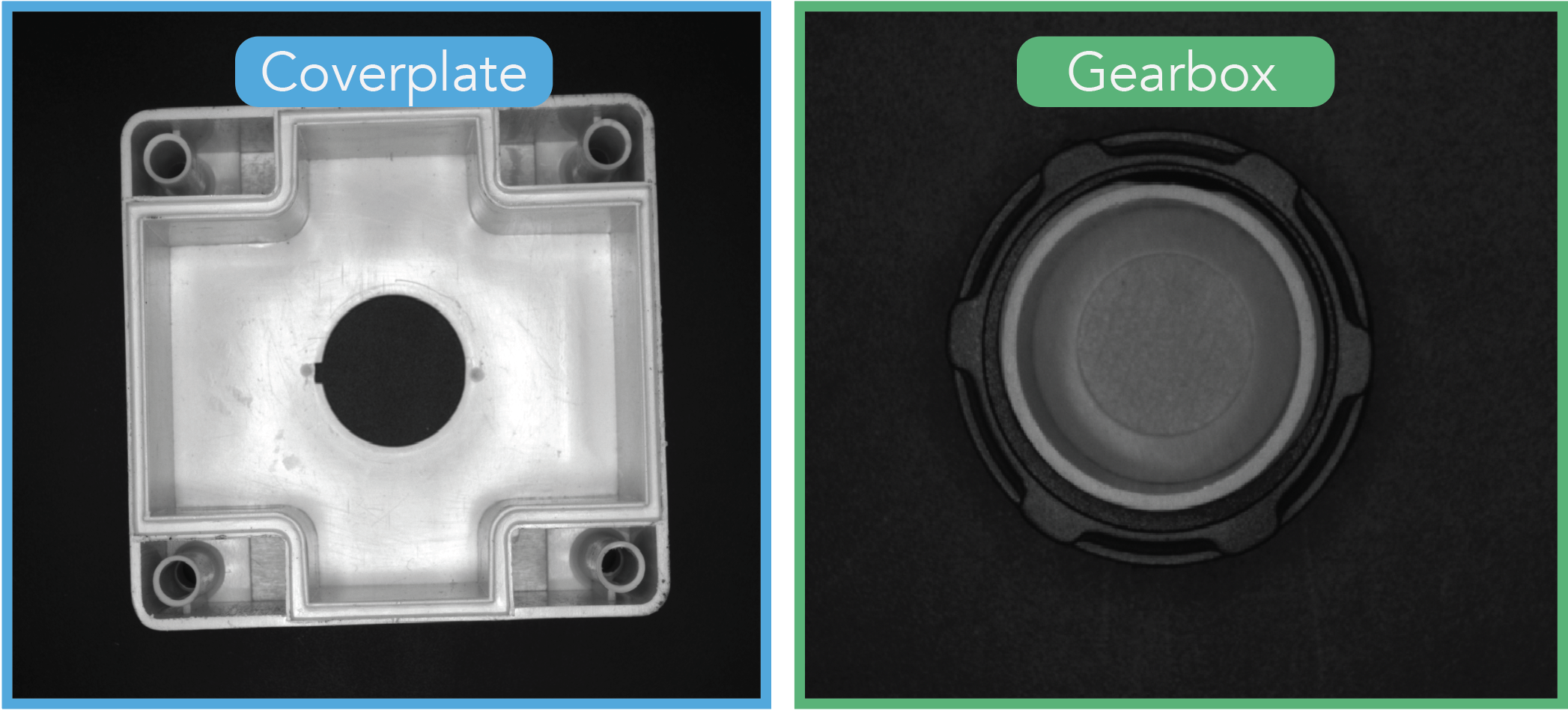

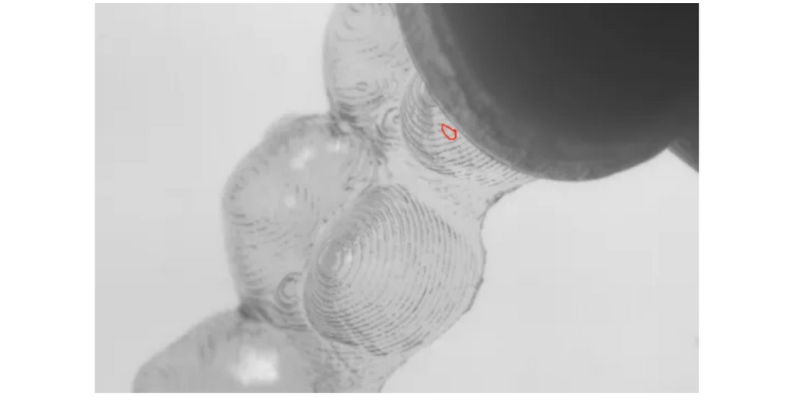

Unsupervised Defect Segmentation

The AI model learns from defect-free images, enabling it to identify defects as deviations from the norm. This eliminates the need for costly defect data collection or defect sample production. Defect images are only required for testing and verification, making it ideal for detecting anomalies when defects or defects categories are unknown in advance.

Instance Segmentation

Identify and separate individual objects within an image, assigning each a unique label. This method provides the precision needed for applications in object tracking, quality inspection, and robotic vision.

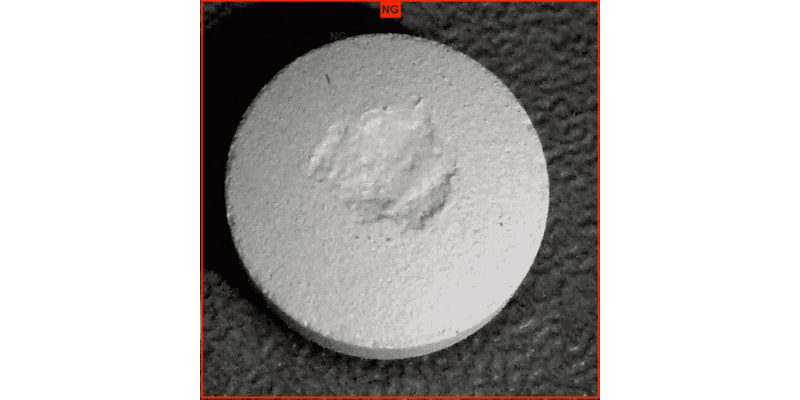

Supervised Defect Segmentation

Trains a model using both defected and non-defected images. The model learns to classify and segment various types of defects, distinguishing between different defect classes. By relying on labeled defect annotations, this model is ideal when precise defect identification is needed.

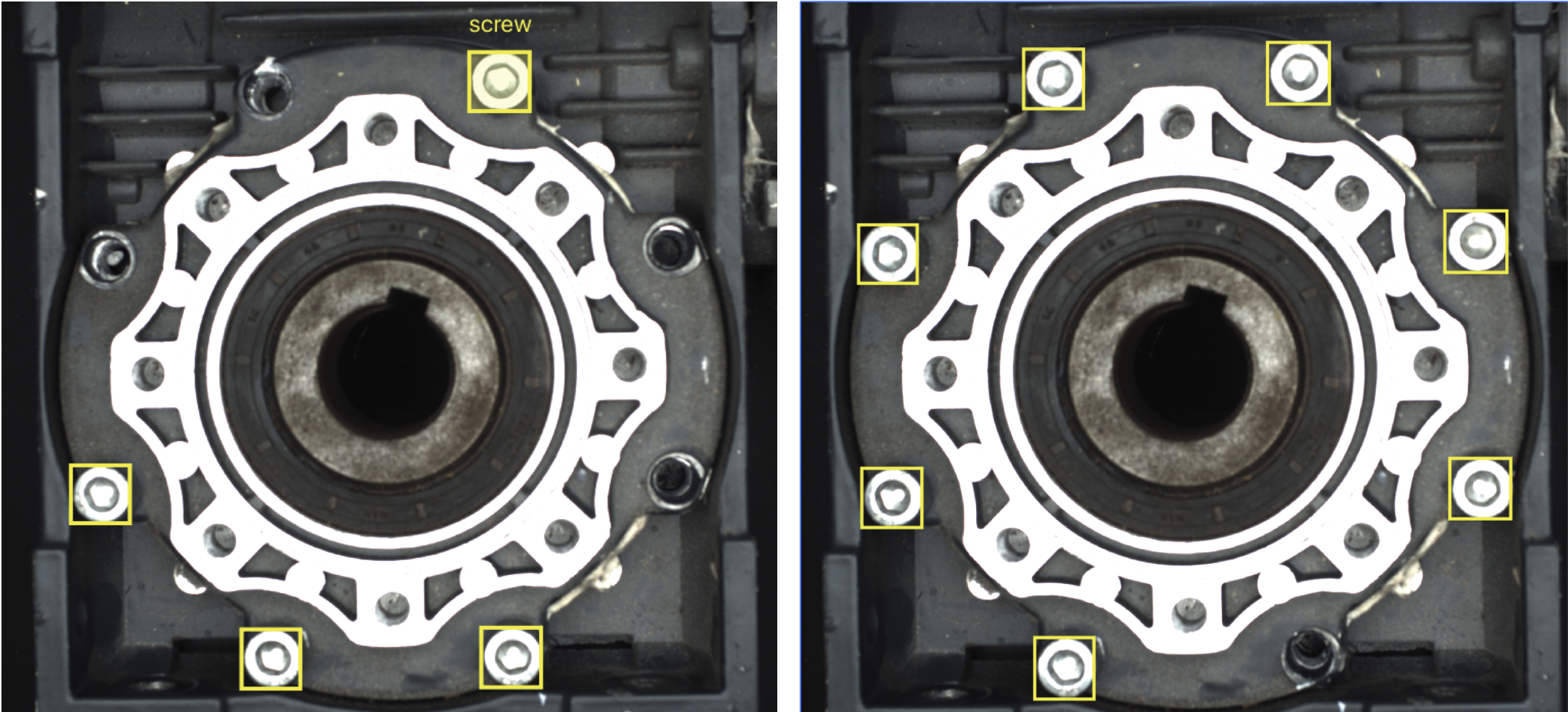

Object Detection

Object Detection can identify and label objects within an image, providing information about their positions, types, and quantity. This technique is useful for applications that need to recognize multiple objects at the same time.

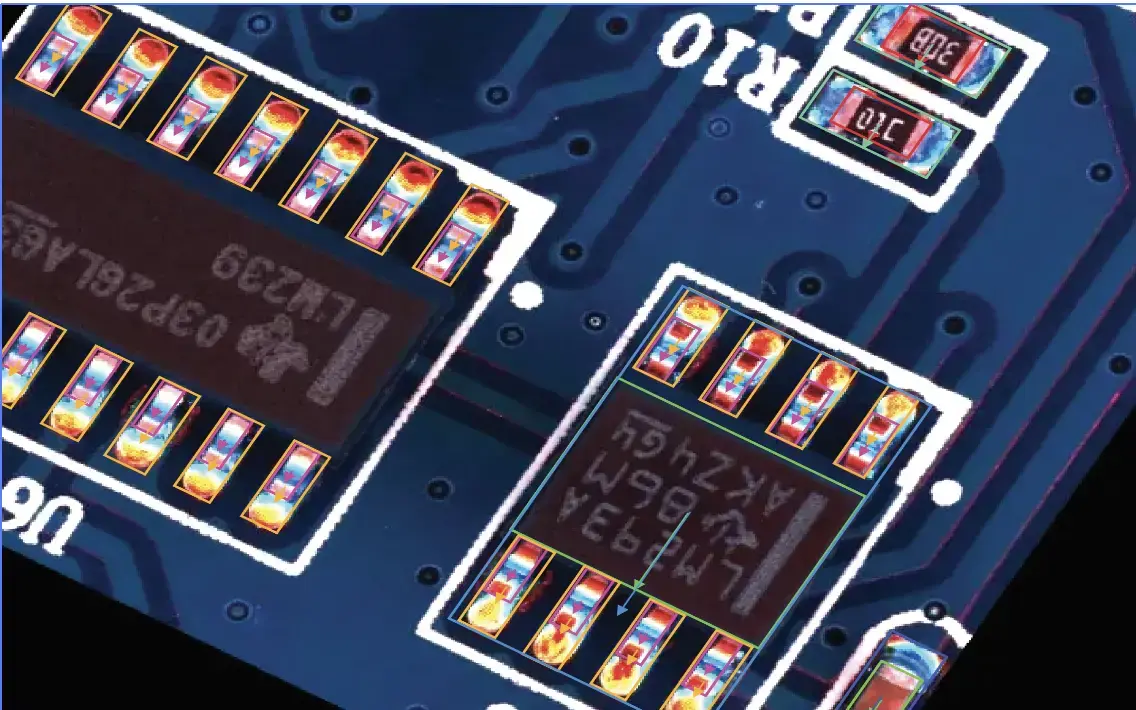

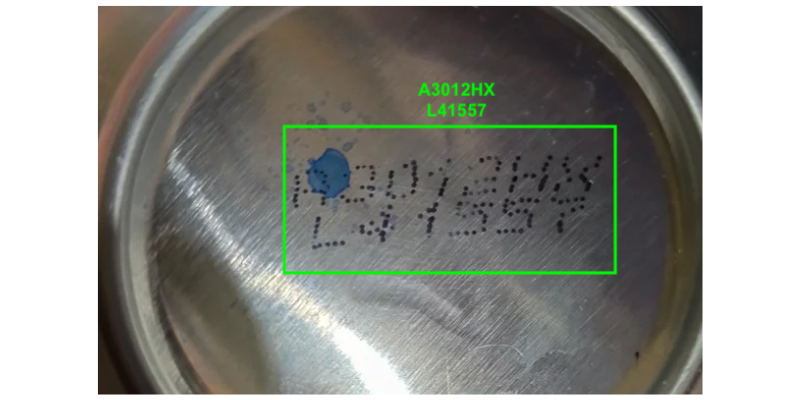

OCR/Text Recognition

Extracts readable text from images, even deciphering deformed or skewed text. It transforms scanned documents, receipts, license plates, and other text-rich visuals into editable and searchable data.

Positioning

Accurately detects and output the location of objects within an image, providing precise spatial data. This capability helps automate processes such as robotic guidance and assembly line monitoring by enabling systems to understand the exact placement of parts and equipment.

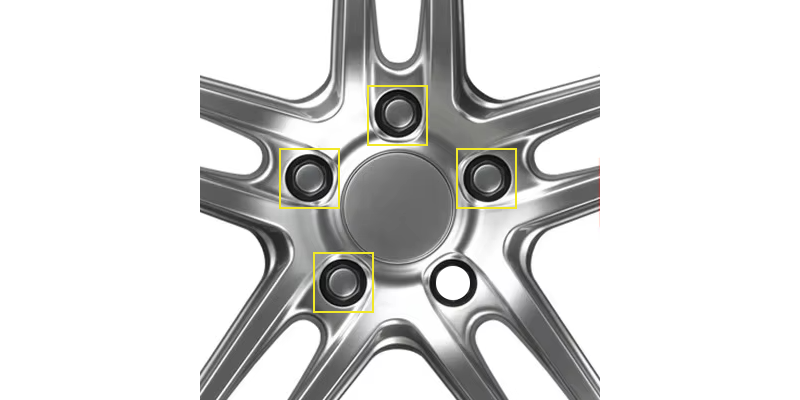

Presence Detection

Identifies the presence of object in the image by searching for each individual item. Commonly used for checking for misplacement and missing parts.

Keypoint Detection

Identify and pinpoint distinctive features or locations in images. These keypoints serve as reference markers for robotic guidance.

Classification

Helps categorize objects within images into specific classes or labels and distinguish between defective and non-defective items.

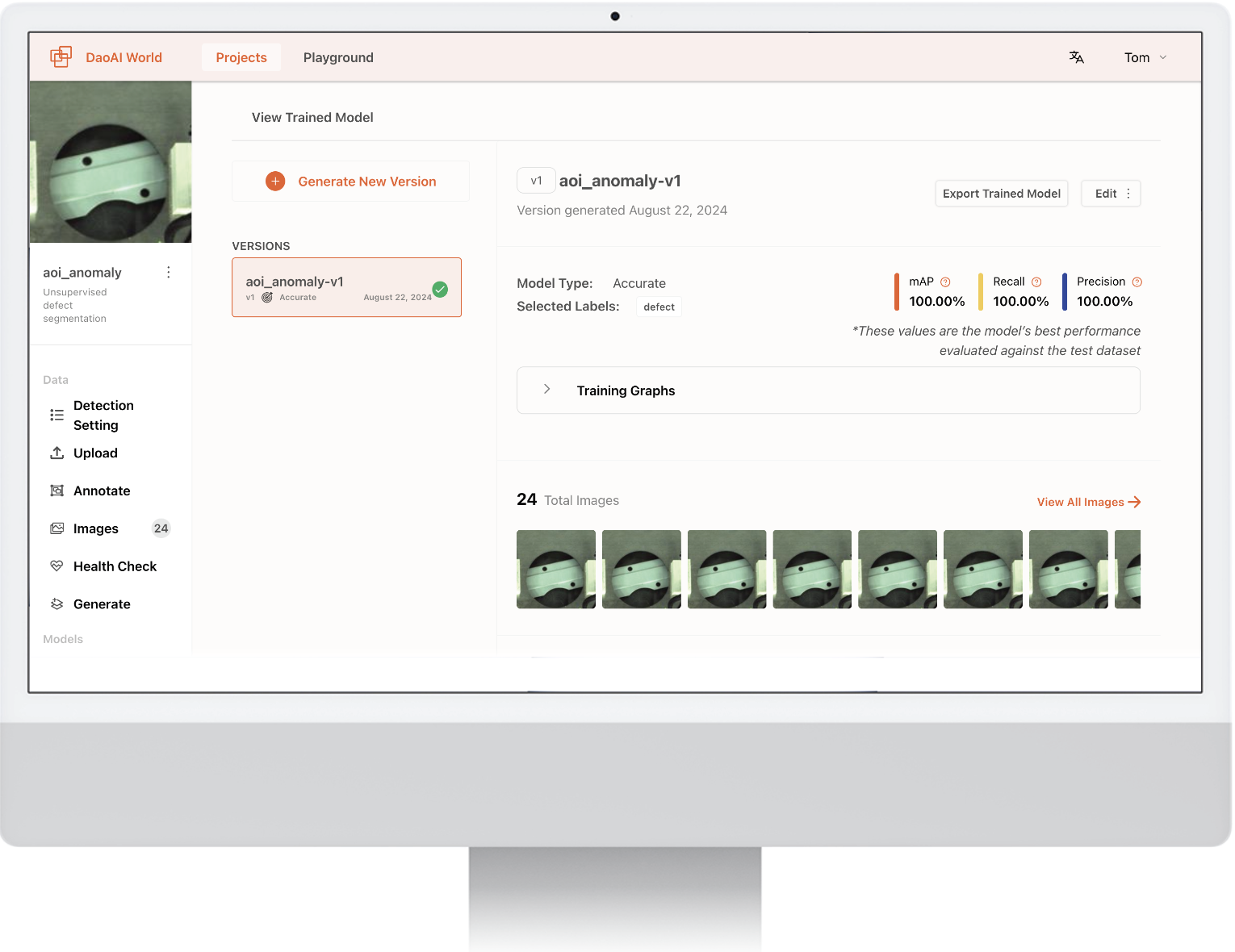

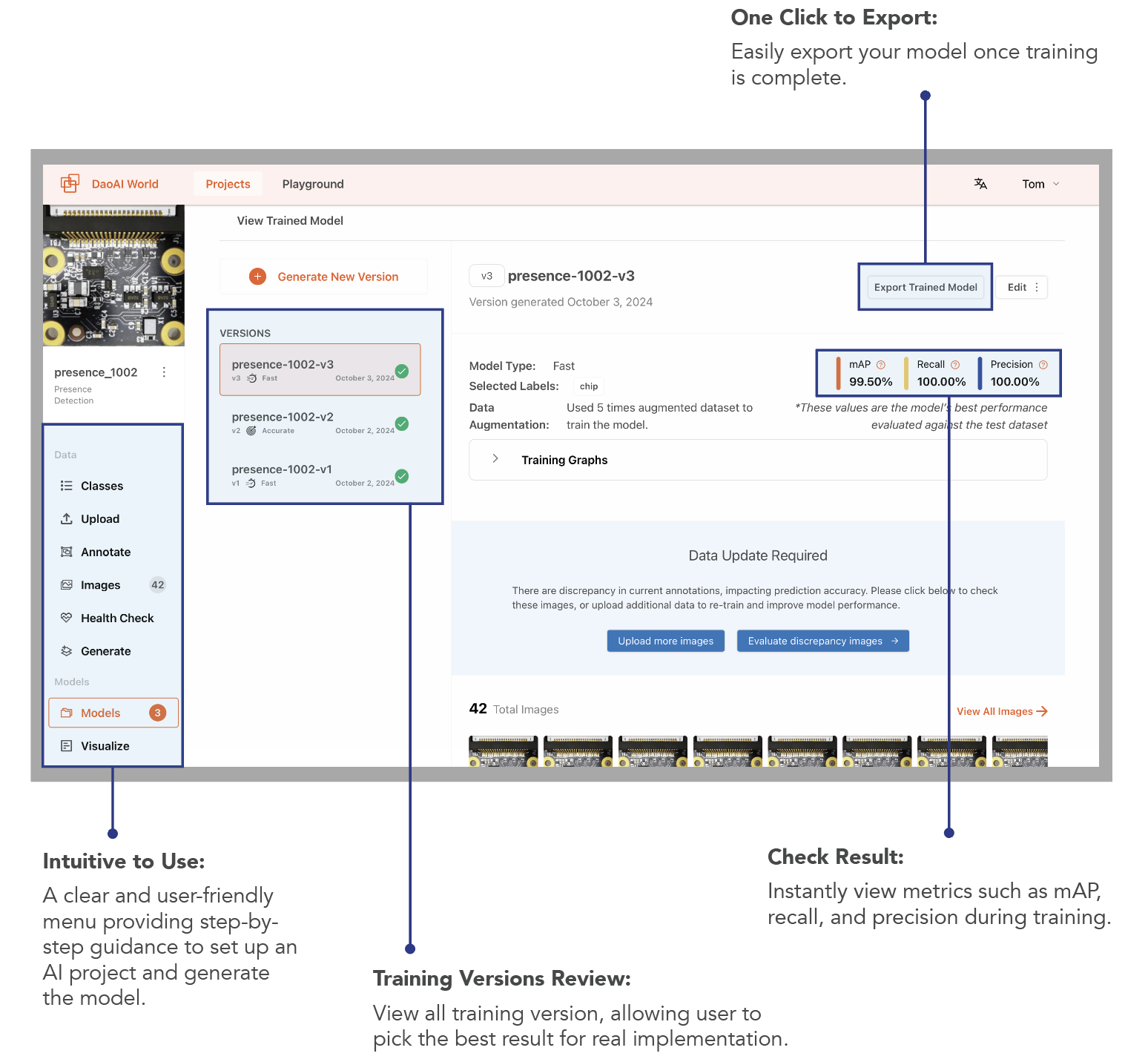

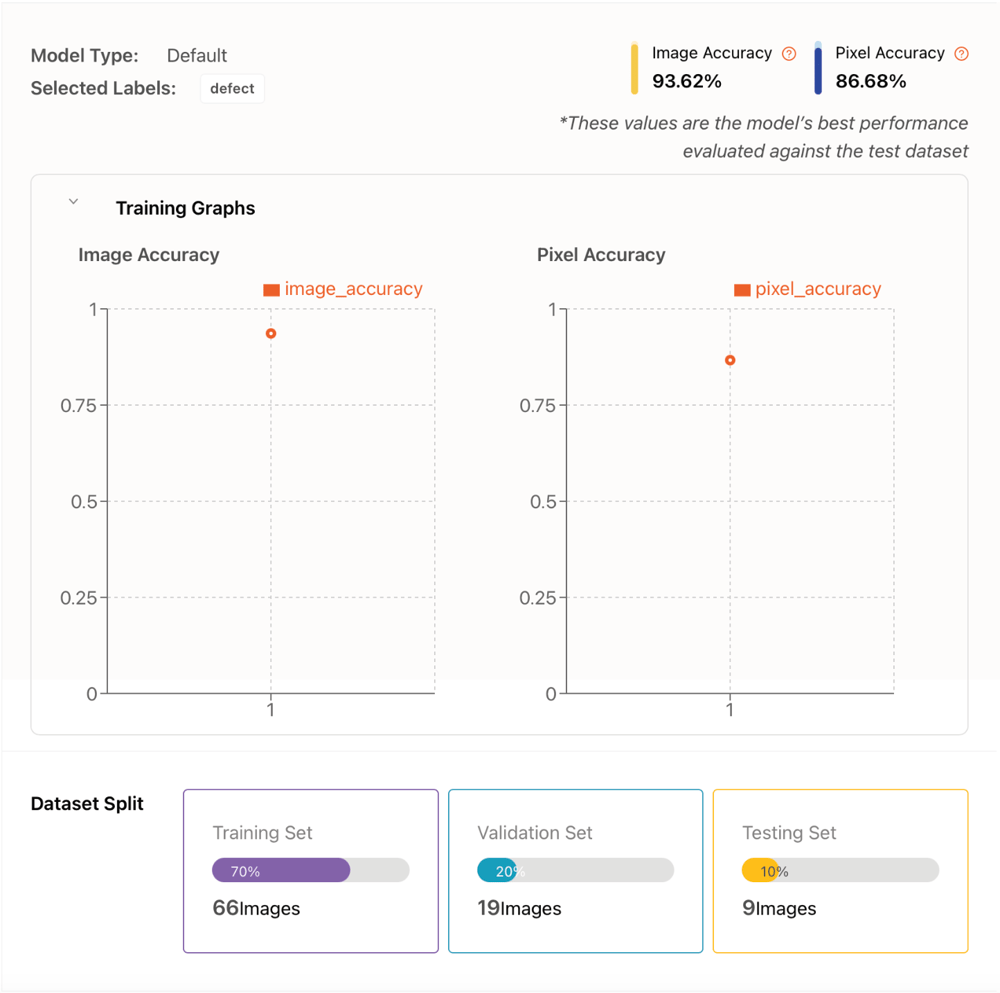

Train Your AI for Optimal Results

We understand the challenges involved in training AI models—it often requires significant resources, including large amounts of data and substantial human effort. DaoAI World is designed to help you overcome these obstacles with ease.

Unsupervised AI Learning With Few Positive Samples Alone

Unsupervised AI learning empowers AI to learn and extract valuable insights from just a few positive samples, without requiring negative or contrasting examples. By identifying patterns, structures, and relationships within the provided data, AI can generalize knowledge and make accurate predictions or classifications. Through this method, users can harness the power of AI to build smarter systems with less data preparation effort.

|

Data Requirement

|

Learning Time

|

|

|---|---|---|

|

Unsupervised AI Learning

|

1-20 positive examples alone | With-in 1 minute |

|

Edge AI

|

Dozens of correct and incorrect image samples | Several minutes |

|

Typical Deep Learning

|

100+ samples | Several hours to days |

Smart Labeling

By combining machine vision with intelligent algorithms, smart labeling allows users to annotate objects with a simple click - eliminating the need to manually trace edges by clicking and dragging.

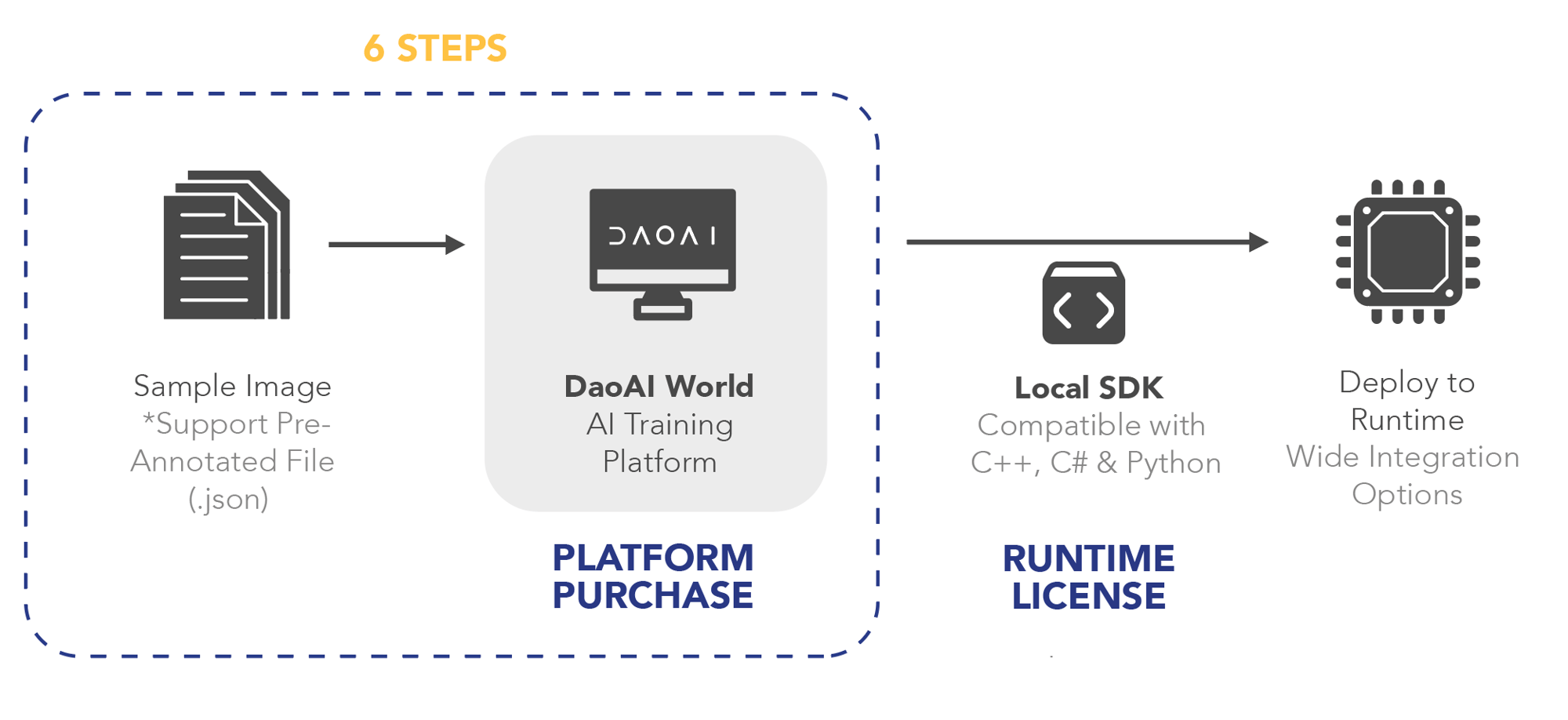

Adaptability and Integration

DaoAI World simplifies the transition from your current platform to runtime deployment. We support direct upload of pre-annotated data (.json) files from existing projects and provide software development kits and multiple deployment method to accelerate implementation.

Transport Format Pre-labeled Data

Upload pre-annotated data to import existing labels and annotations, saving time and preventing duplicate work.

COCO JSON

Pascal VOC

YOLO v8 Pytroch

YOLO v5 Pytorch

VGG Image Annotator

JSON (VIA)

Flexible Integration

DaoAI offers versatile and efficient solutions to meet the varying needs of users with different computational and operational requirements.

Data Sharing and Monitoring

Supports real-time collaboration that enables team members to work on the same project. Allowing multiple users to annotate data, adding new training sessions or fixing errors, simultaneously. Bring consistency and efficiency in the annotation process.

Entire machine learning pipeline exists in one central repository for data monitoring. Shared accounts (“Workspaces”) house all source images, annotations, datasets and trained models (both ready to be deployed, and actively in-deployment).

From Training to Deployment

Optimization and Scalability Tailored to Your Needs

|

ENTERPRISE Beginner |

ENTERPRISE Regular |

ENTERPRISE Pro |

INDUSTRIAL Beginner |

INDUSTRIAL Regular |

INDUSTRIAL Pro |

|

|---|---|---|---|---|---|---|

|

GPU |

NVIDIA RTX 4080 16G x 4 |

NVIDIA RTX 4090D 24Gx 4 |

NVIDIA RTX 4090D 24Gx 8 |

NVIDIA RTX 4060 Ti |

NVIDIA RTX 4080 |

NVIDIA RTX 4080 + RTX 4060 Ti |

|

CPU |

Intel Xeon Gold 6330 x2 |

Intel Xeon Gold 6330 x2 |

Intel Xeon Gold 6330 x2 |

Intel Core i7-10700K |

Intel Core i7-10700K |

Intel Core i7-10700K |

|

Storage |

480GB SATA SSD 2.5in x 13.84TB SATA SSD 2.5in x 5 |

480GB SATA SSD 2.5in x 13.84TB SATA SSD 2.5in x 5 |

480GB SATA SSD 2.5in x 13.84TB SATA SSD 2.5in x 5 |

1TB SSD M.2 |

1TB SSD M.2 |

2TB SSD M.2 |

|

RAM |

32GB DDR4 x 8 |

32GB DDR4 x 8 |

32GB DDR4 x 8 |

16GB DDR4 x 2 |

16GB DDR4 x 2 |

32GB DDR4 x 2 |

APPLICATIONS

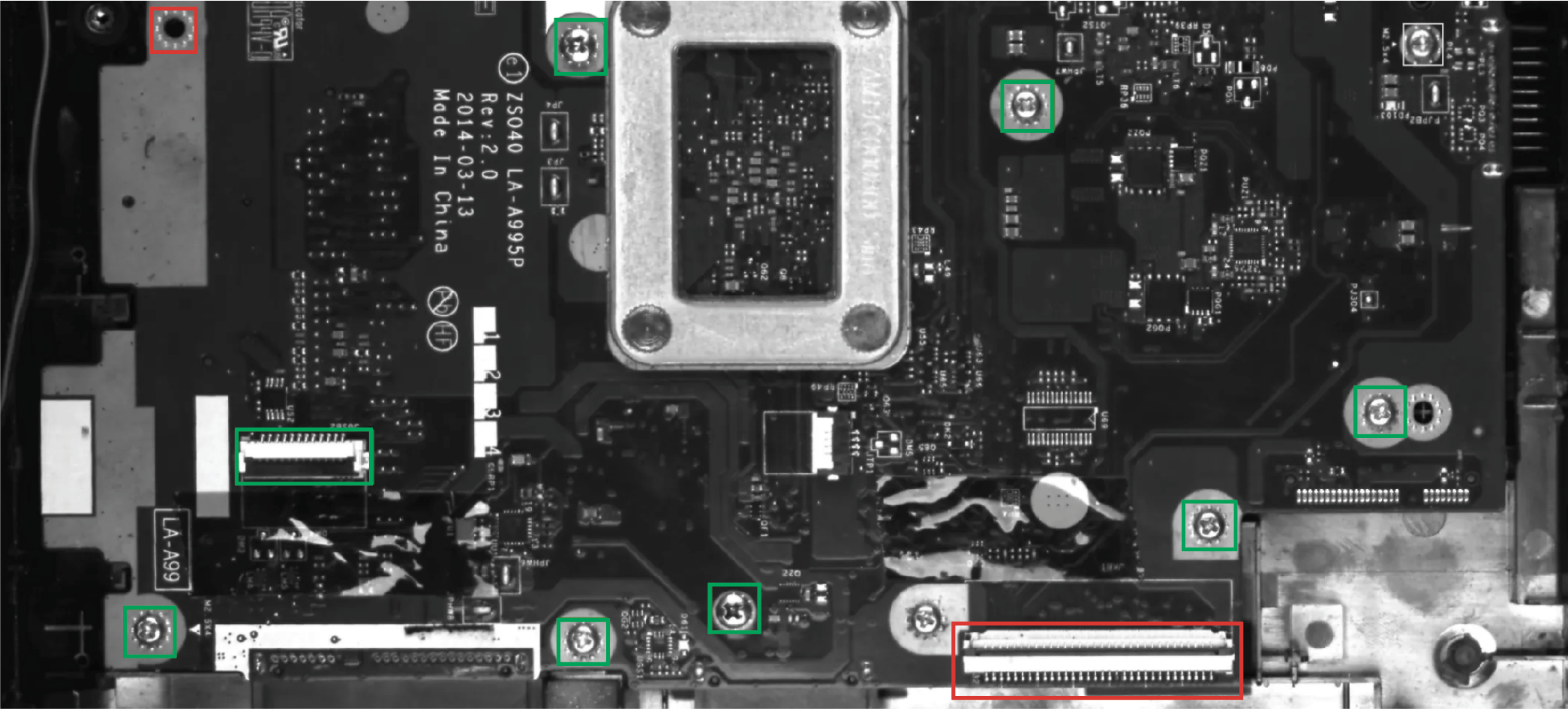

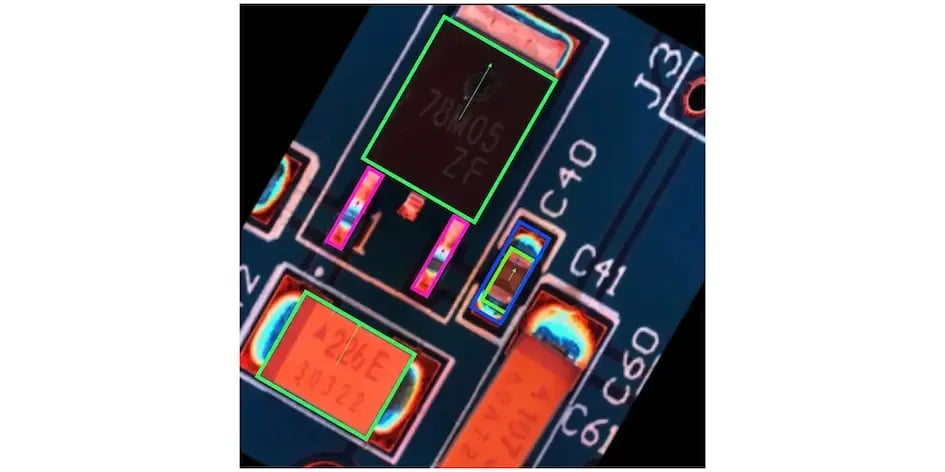

%20(2).png?width=1920&height=960&name=AOI%E7%B6%AD%E4%BF%AE%E7%AB%99%20(1920%20x%20960%20px)%20(2).png)

Hybrid model

Rotated Object Detection

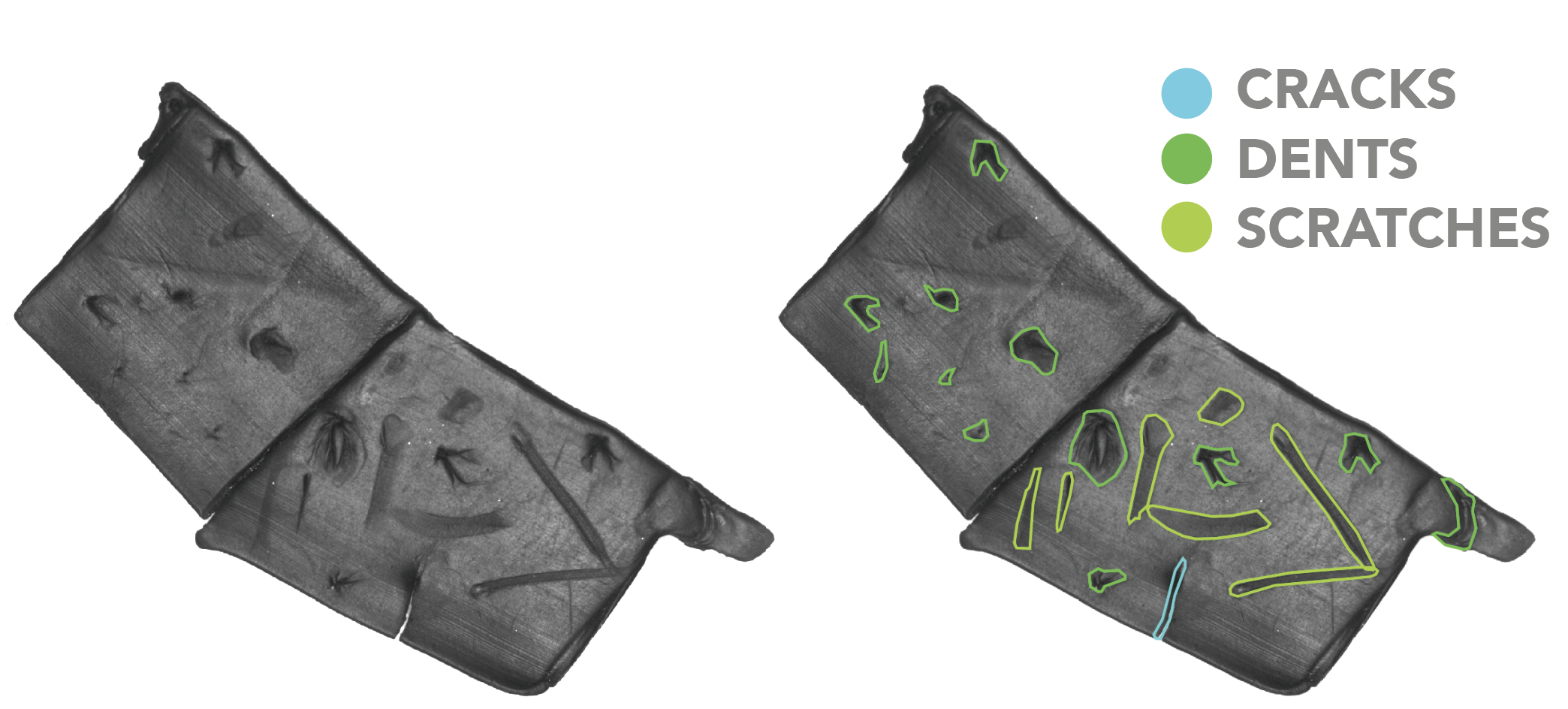

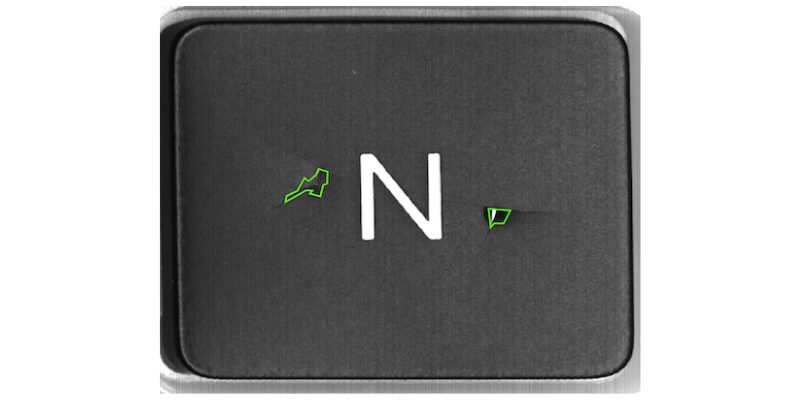

%20(3).webp?width=945&height=472&name=AOI%E7%B6%AD%E4%BF%AE%E7%AB%99%20(1920%20x%20960%20px)%20(3).webp)

Unsupervised defect segmentation

Electronics

Unsupervised Defect Segmentation

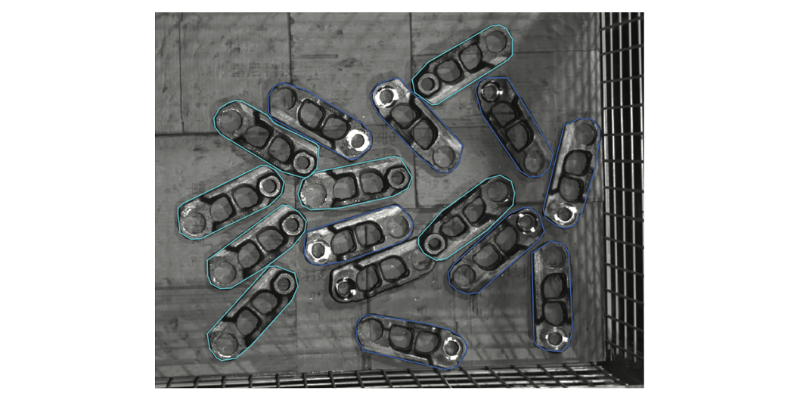

Machinery Manufacturing

Instance Segmentation

Object Detection

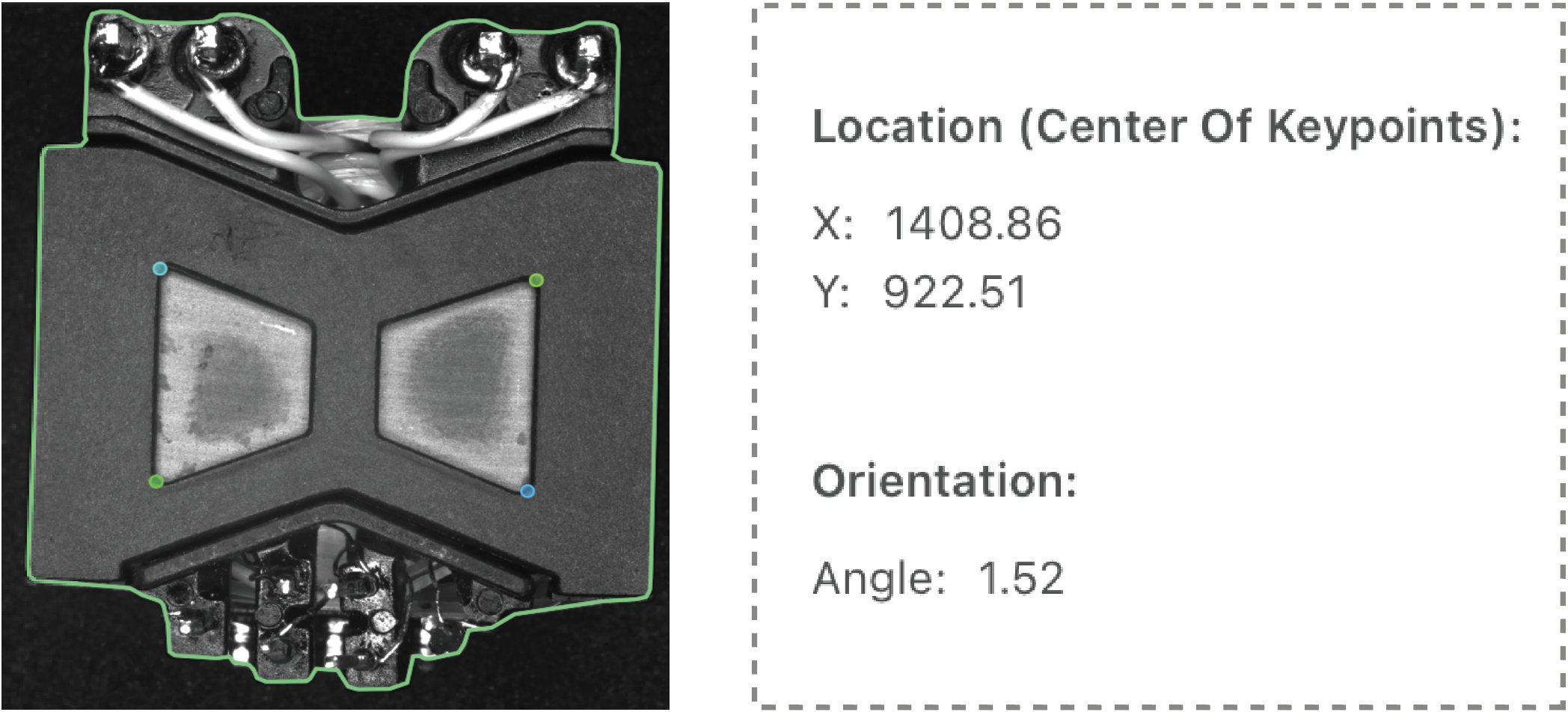

Robotic Automation

Keypoint Detection

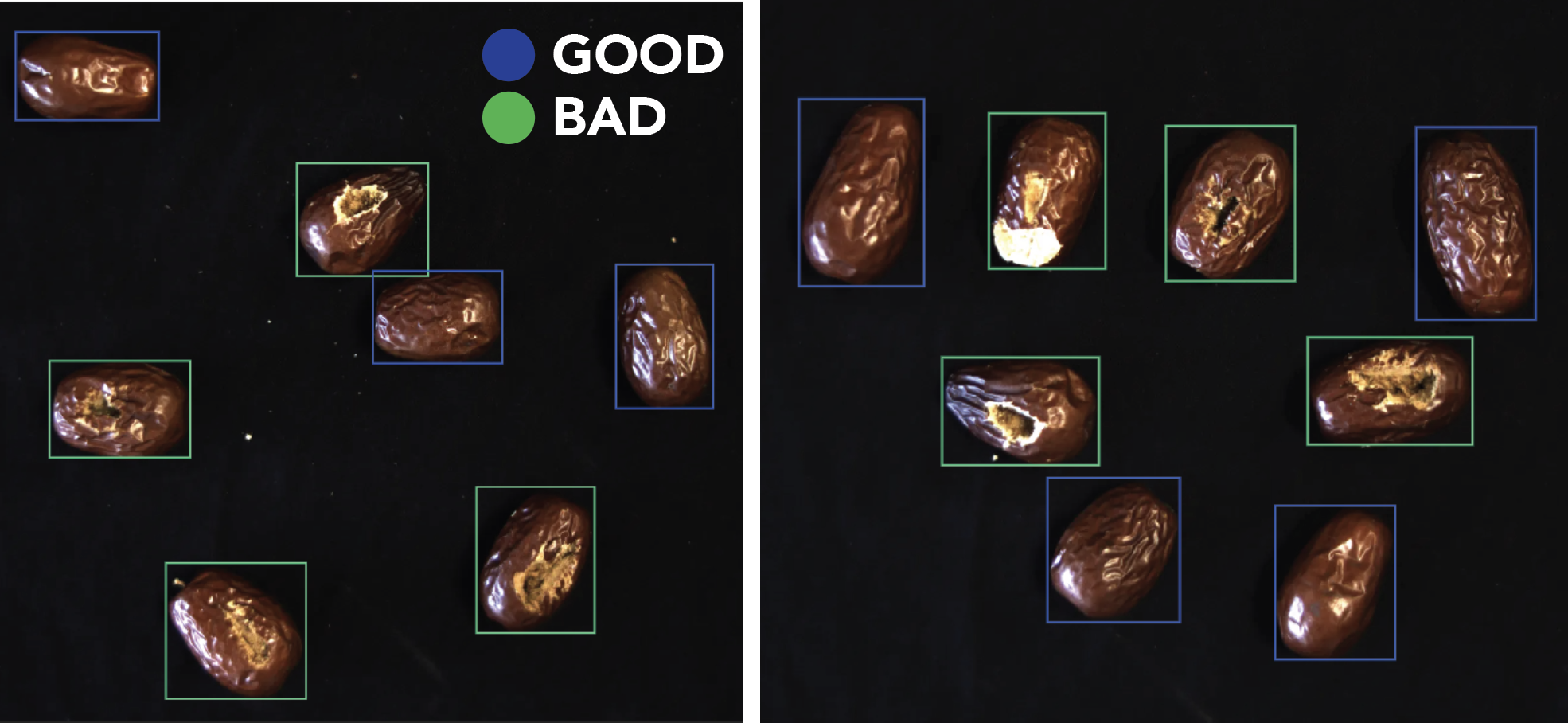

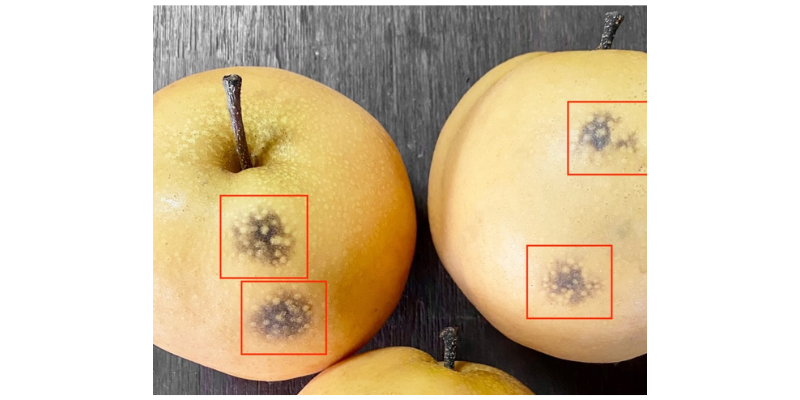

Packaging Industry

Instance Segmentation

Supervised Defect Segmentation

Automotive Assembly Inspection

Presence Detection

Machinery Manufacturing

Positioning

Classification