In the modern chemical industry, crystal inspection has a crucial impact on the quality and performance of products. However, traditional manual detection methods are not only inefficient, but also susceptible to subjective judgment, resulting in insufficient accuracy. DaoAI developed an efficient and automated crystal inspection system for a leading German chemical company with a history of 140 years. The company is mainly engaged in the research and development, production and sales of chemical products, which are widely used in plastics, rubber, coatings, medicine and other fields. They have been looking for advanced technologies and solutions to improve product quality and production efficiency.

Challenge: Bottlenecks in Manual Detection

In chemical production, the shape, particle size and distribution of crystals directly affect product performance and quality. However, there are many challenges with traditional manual inspection methods:

- Inefficient: Relying on the human eye to observe and measure, the entire process is insufficient and time-consuming.

- Limited accuracy: Manual interpretation is easily affected by subjective factors, and it is difficult to ensure consistency.

- High cost: The training and input cost of professional and technical personnel is high.

To overcome these problems, DaoAI provides an automated inspection solution based on AI vision technology.

Solution: AI-driven Intelligent Inspection System

The AI crystal inspection system, developed using DaoAI World, utilizes an auto-segmentation model and customized algorithms to accurately analyze crystal characteristics. It focuses on the following key points:

- Crystal coverage detection: Through image analyzing technology, the distribution range of crystals on the surface of the material is automatically calculated to ensure production standards are met.

- Crystallization feature analysis: The AI model can distinguish between three different crystalline morphologies (lumpy, flake, and hybrid) to provide more in-depth material analysis.

- Average particle size calculation: Through high-precision image processing, the crystal size is automatically measured to ensure that the particle size distribution meets the product requirements.

These technologies not only improve the inspection efficiency, but also reduce the rate of defective products in the production process and ensure consistent product quality.

The accuracy of an AI model relies on high-quality data annotation. In order to improve the detection accuracy, we adopted a multi-resolution sample strategy and a high-precision sample strategy

- 500x microscopic image: Mainly used to calculate coverage and crystallization characteristics, ensuring accuracy and efficiency.

- Additional annotation of 1k and 2k resolution samples for auxiliary training and validation: To further improve the accuracy and performance of the model, we additionally annotated 1k and 2k resolution samples as auxiliary training and validation data.

- 2K samples for accurate grain size and size distribution: We prioritize using 2K high-resolution samples. These high-resolution images provide clearer and more detailed crystal structures, enabling the AI model to measure grain size and distribution more accurately.

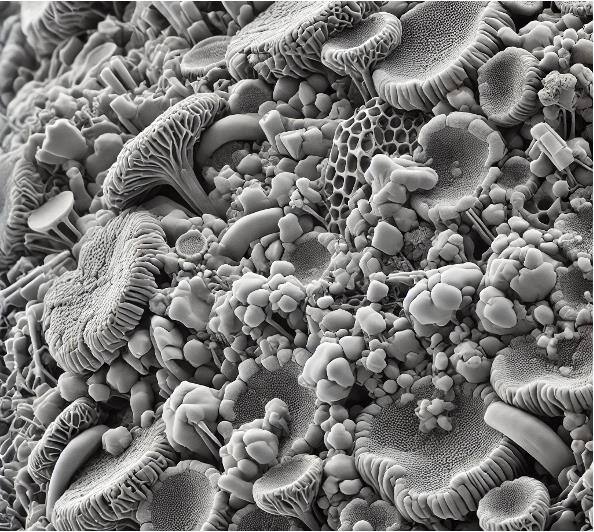

Original Figure

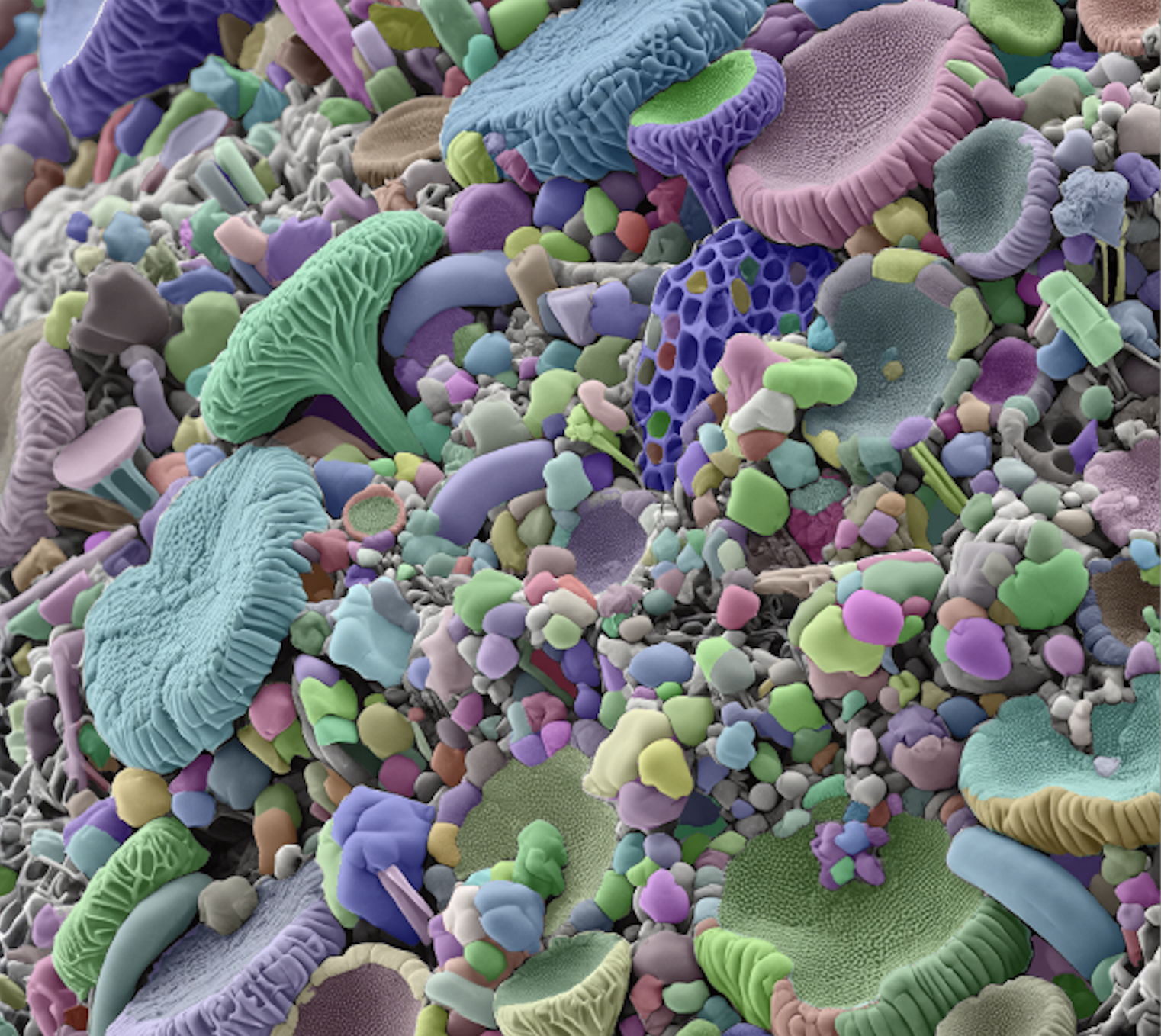

DaoAI World Inference Output

In multiple tests and experiments, the AI crystal inspection system has demonstrated accuracy close to that of manual inspection, while significantly outperforming in efficiency:

- Coverage Testing: While manual inspection can only provide a rough, subjective estimate of coverage, AI offers a quantitative result. Providing accurate data for measurement and analysis.

- Crystal Type Analysis: The model accurately classifies flaky crystals, matching the results of manual inspection.

- Average Grain Size Measurement: Manual inspection cannot provide precise measurements and is time-consuming. AI’s calculated results have minimal error compared to standard samples, meeting production requirements.

In addition, the system can generate detailed statistical reports, helping businesses monitor the production process and optimize operations to achieve higher production quality standards.

DaoAI’s AI vision technology is continuously driving the intelligent transformation of the chemical industry, enabling companies to improve inspection efficiency, reduce production costs, and ensure stable product quality. Our AI crystal inspection system has already demonstrated outstanding results in real-world applications, providing reliable solutions for industries such as chemicals, pharmaceuticals, and materials science.

If your business is looking for efficient and accurate automated inspection technology, now is the best time! Contact DaoAI to learn more about our AI inspection solutions and how we can make your production process smarter and more efficient.

Get in touch with the DaoAI team today to explore how AI can help your business move into the future!

FAQ

1. What challenges do traditional crystal inspection methods present in the chemical industry?

Traditional crystal inspection methods in the chemical industry are often manual, relying on human observation and measurement. This approach is:

-

Inefficient: Manual inspections are time-consuming and labor-intensive.

-

Subjective: Results can vary between inspectors, leading to inconsistencies.

-

Costly: Training skilled personnel and maintaining manual inspection processes incur high costs.

These challenges can lead to errors and reduced product quality, especially in processes requiring high precision.

2. How does DaoAI's AI-driven crystal inspection system address these challenges?

DaoAI's AI-powered inspection system automates the crystal analysis process, offering:

-

High Accuracy: Utilizes advanced image processing to detect and analyze crystal structures precisely.

-

Efficiency: Automates tasks that were previously manual, reducing inspection time.

-

Consistency: Eliminates human subjectivity, ensuring uniform results across inspections.

This system enhances product quality and reduces operational costs by streamlining the inspection process.

3. What specific features does the AI inspection system analyze?

The AI system focuses on several critical aspects of crystal inspection:

-

Crystal Coverage Detection: Calculates the distribution range of crystals on material surfaces.

-

Crystallization Feature Analysis: Differentiates between various crystalline morphologies, such as lumpy, flake, and hybrid forms.

-

Average Particle Size Calculation: Measures crystal sizes to ensure they meet product specifications.

These analyses help maintain high-quality standards in chemical products.

4. How does high-resolution imaging enhance the AI model's accuracy?

High-resolution imaging provides detailed visual data, which is crucial for accurate analysis.

-

500x Microscopic Images: Used for calculating coverage and crystallization characteristics.

-

1K and 2K Resolution Samples: Serve as auxiliary training and validation data to improve model performance.

-

2K High-Resolution Samples: Prioritized for measuring grain size and distribution with greater precision.

These high-quality images enable the AI model to detect subtle differences in crystal structures, enhancing inspection accuracy.

5. What benefits does the AI inspection system offer to chemical manufacturers?

Implementing DaoAI's AI inspection system provides several advantages:

-

Improved Product Quality: Ensures consistent and accurate inspections, leading to higher-quality products.

-

Operational Efficiency: Reduces inspection times and labor costs through automation.

-

Scalability: Easily integrates into existing production lines, accommodating various scales of operation.

-

Data-Driven Insights: Provides detailed analytics for continuous process improvement.

These benefits contribute to enhanced competitiveness and profitability in the chemical industry.