DaoAI Story

High-Precision Drug Defect Detection with AOI Systems

Background / Pain Points Introduction

Modern medicine is booming, and the demand for medicines is increasing day by day. For drug manufacturers, drug testing is a crucial procedure, which is directly related to the safety, efficacy and health of patients. There are many pain points and challenges that production enterprises must face;

- Frequent mold changes (variety of drug product specifications): Drug products come in a variety of forms, including tablets, capsules, liquids, powders, etc., each with its own specific testing requirements and challenges.

- High-speed production demand: Modern pharmaceutical production lines pursue high efficiency, but conventional visual inspection systems are difficult to handle such a large amount of concurrent data. If the drug inspection speed lags the speed of the production line, it will produce untimely feedback, resulting in a large number of ineffective production and further cost.

- Difficult to obtain defective samples: It is expensive to reproduce defective data samples for pharmaceutical products. How to efficiently use and analyze existing samples has become a major challenge.

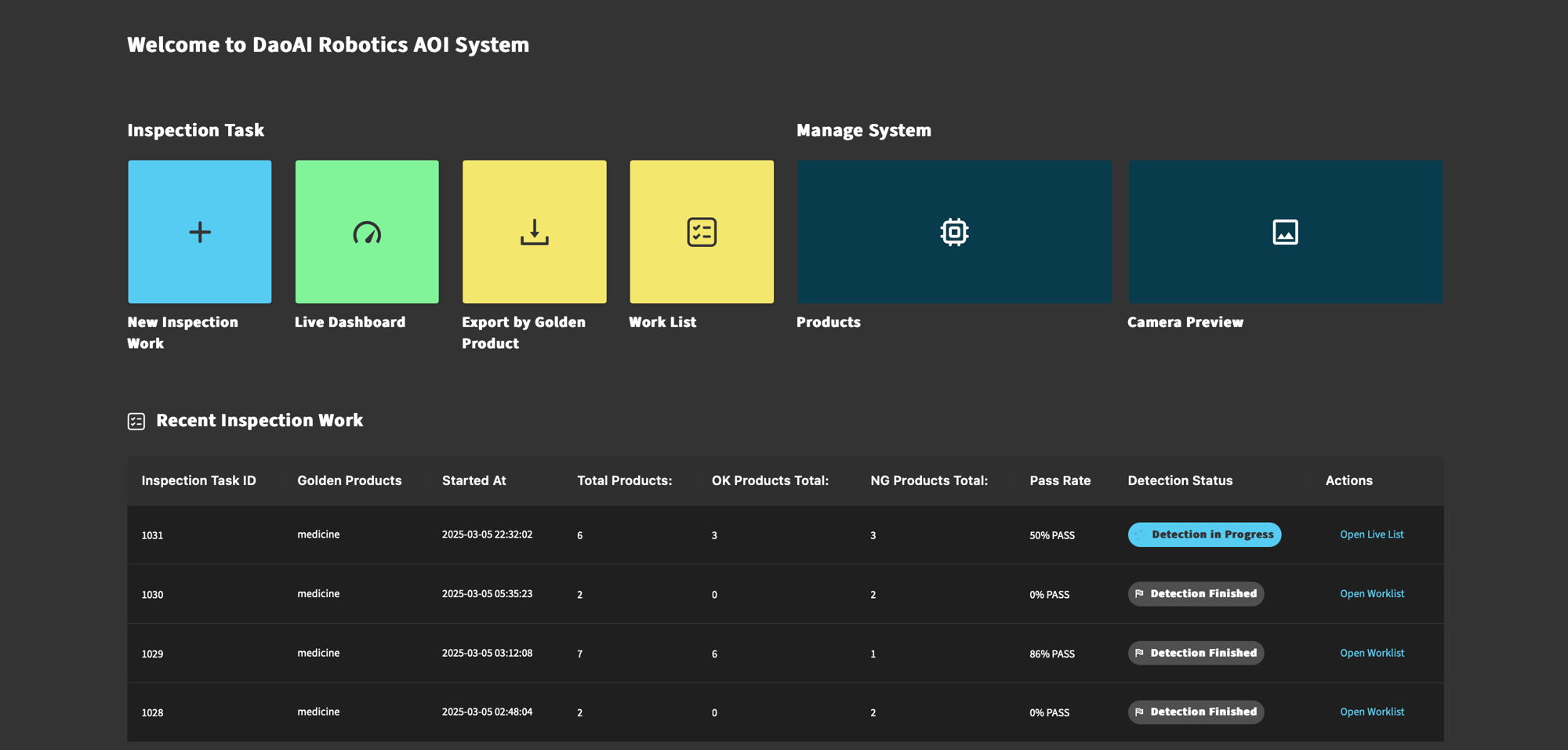

Usage Process

Through this tutorial, you will be familiar with all the steps required to build a DaoAI AOI drug inspection model.

Step 1: On the Manage Project page, create a new inspection work.

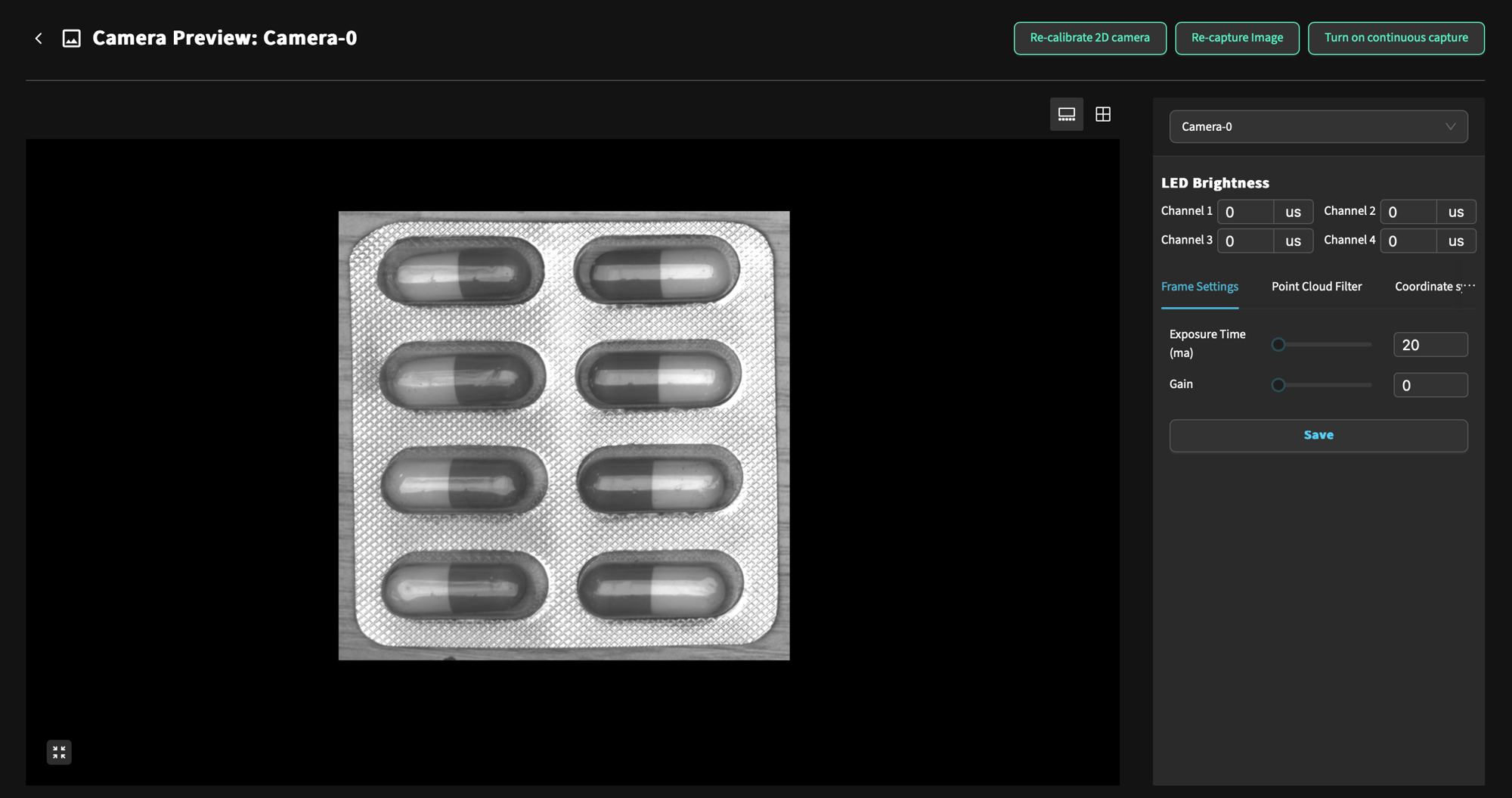

Step 2: Capture an image of the current product sample via the photo button in the upper right corner.

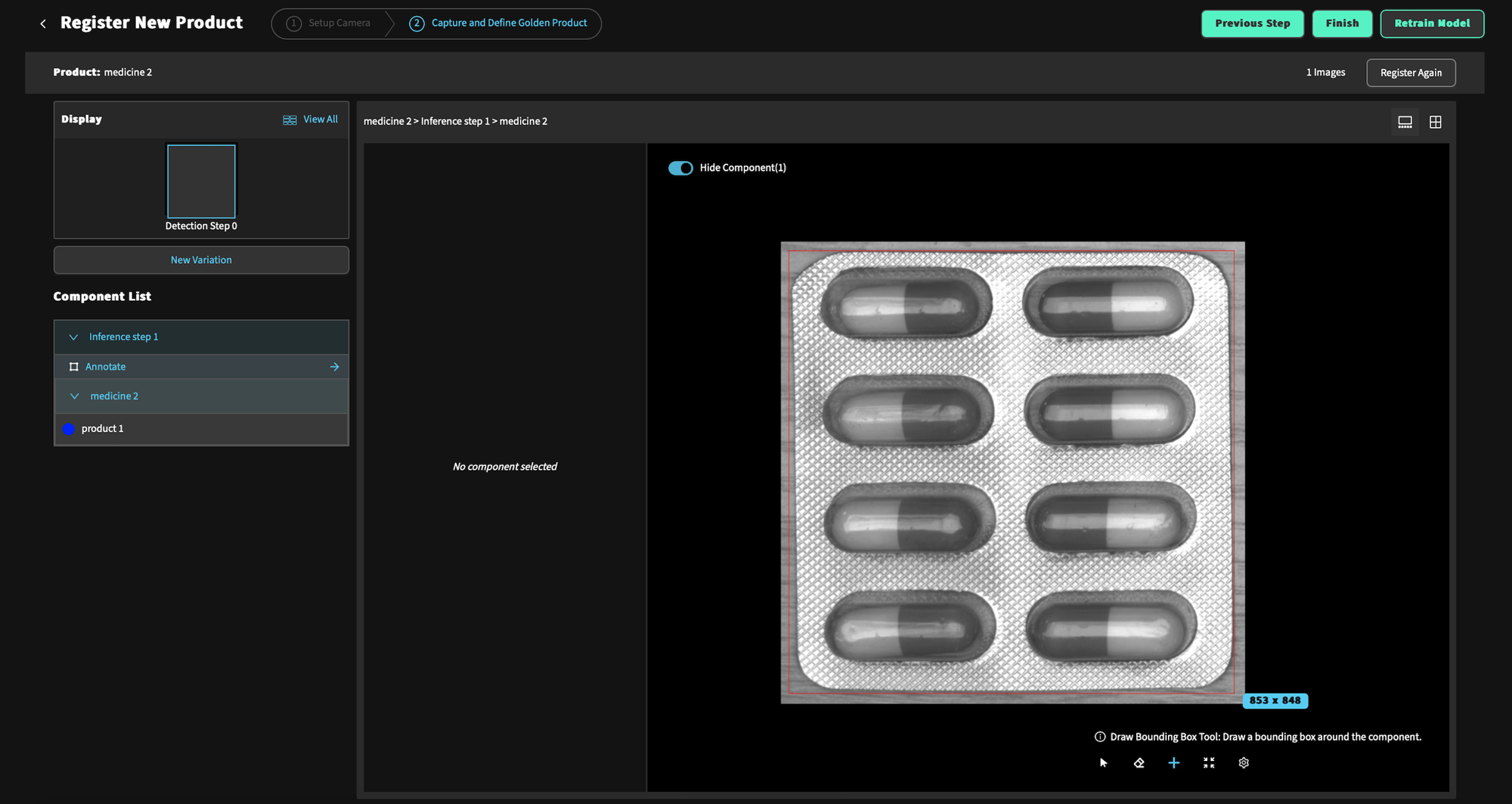

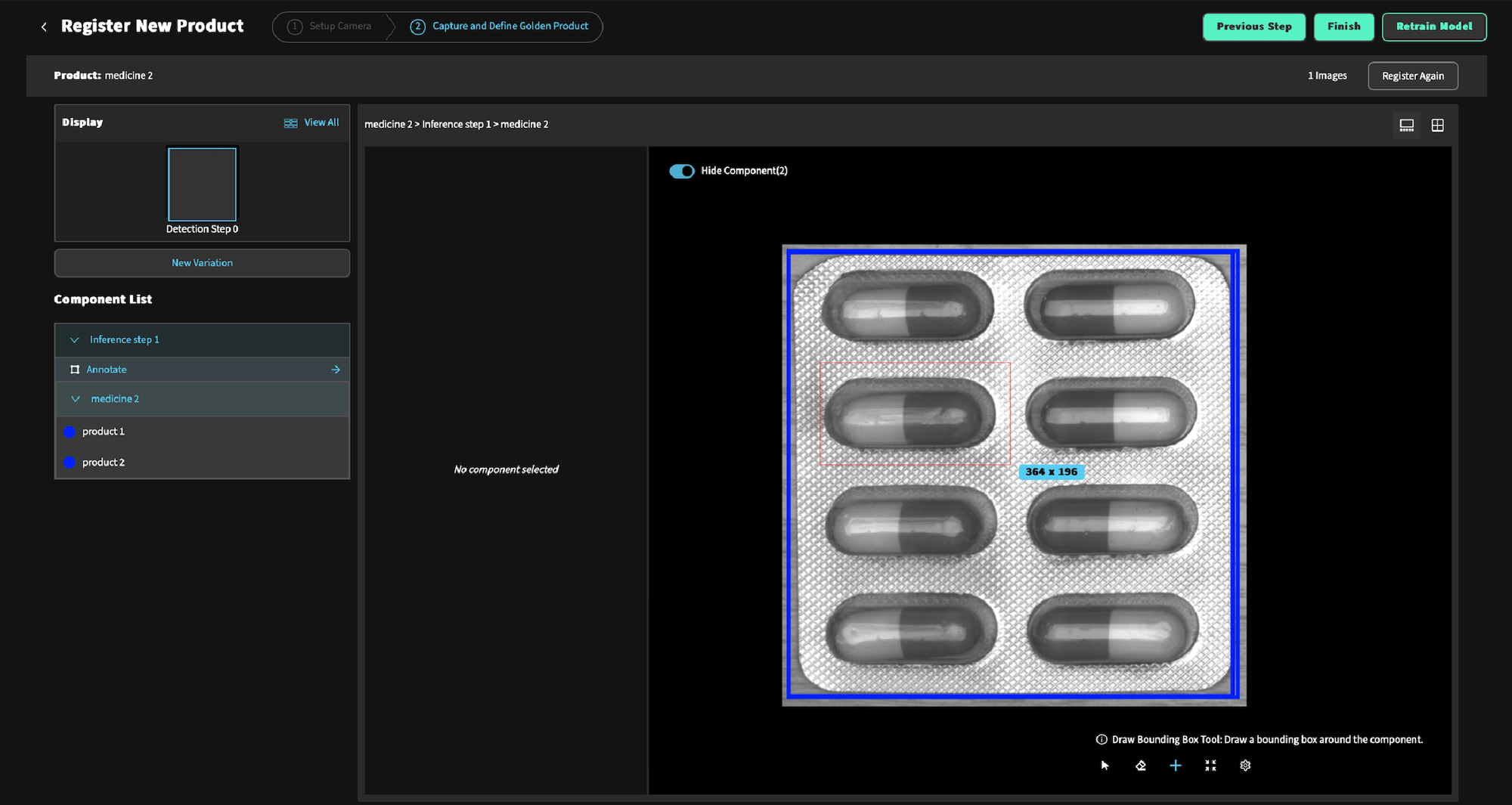

Step 3: Through the toolbar in the lower right corner, click the annotation tool. Select the entire item as a "product", then mark each area that needs to be detected, and add new labels for each of them. (In this case, you can name them pills, cover, etc.)

Repeat the above steps until all the areas you want to detect are labeled, click Start Training, and return to the main page and wait for the model to be trained.

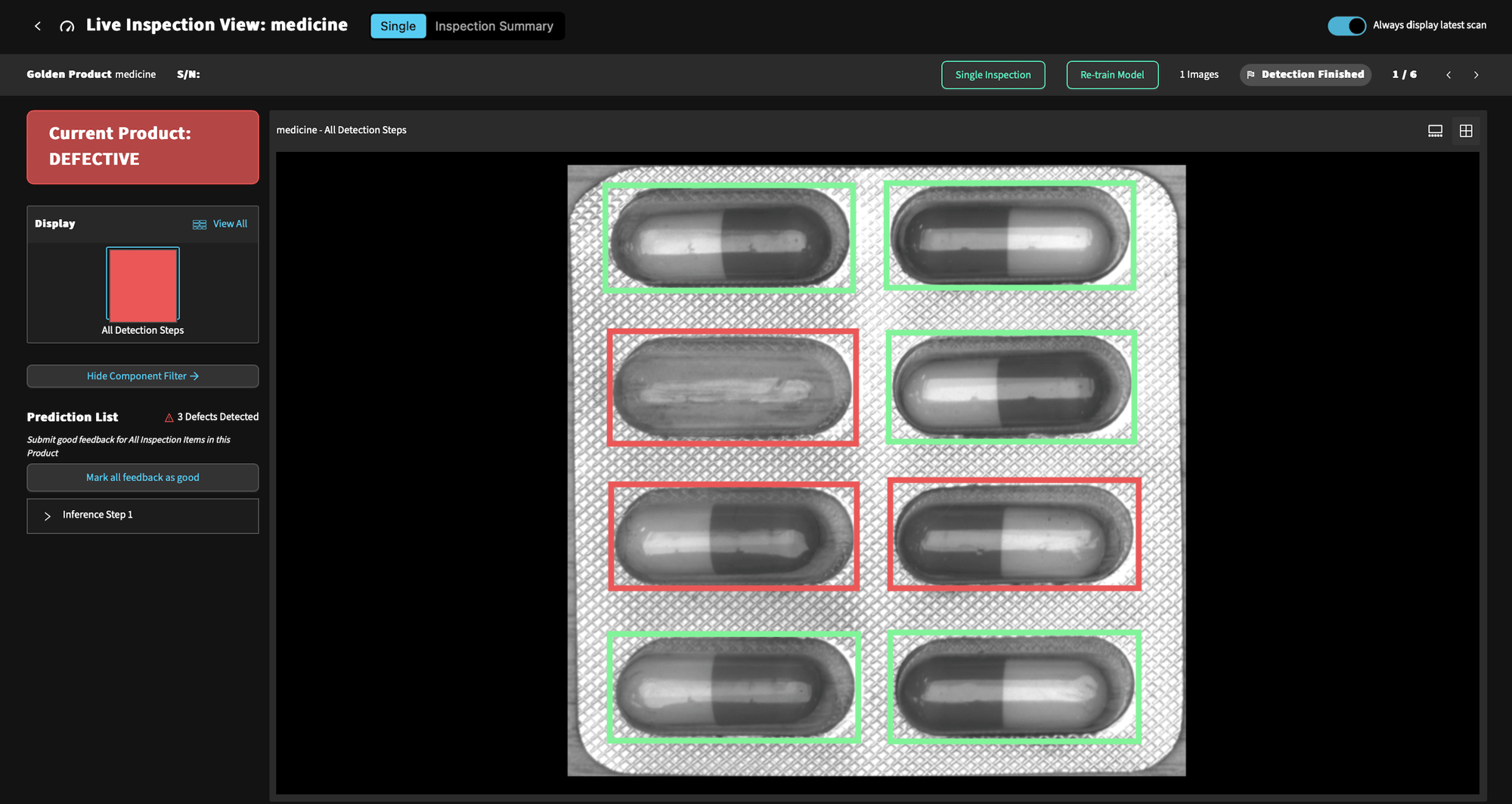

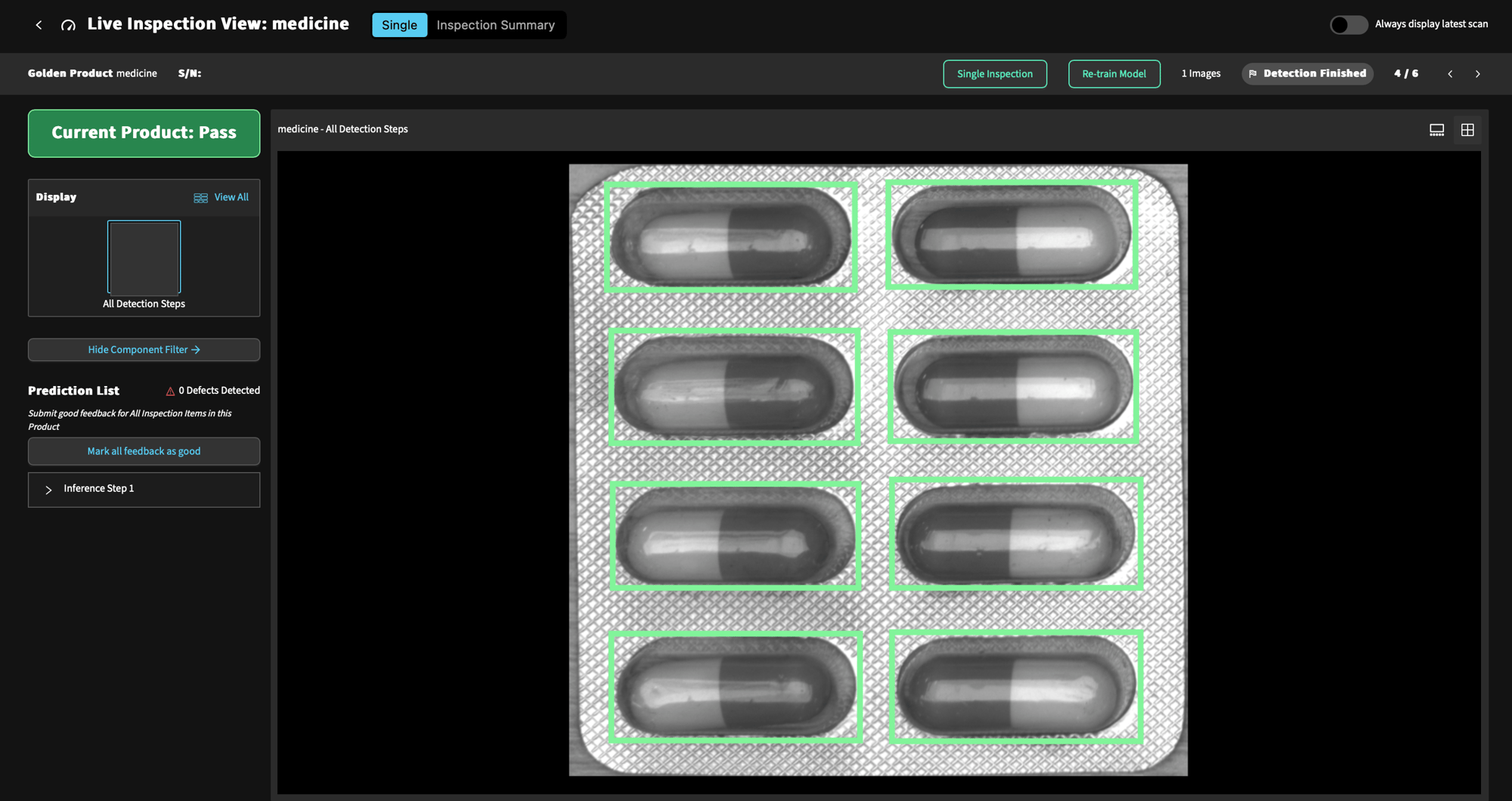

Step 4: Use the trained model to create a detection task. As shown in the figure, any anomalies can be accurately identified (including defects such as wrong placement, missing installation, broken capsule body, etc.)

Step 5: DaoAI AOI's unique feedback loop mechanism

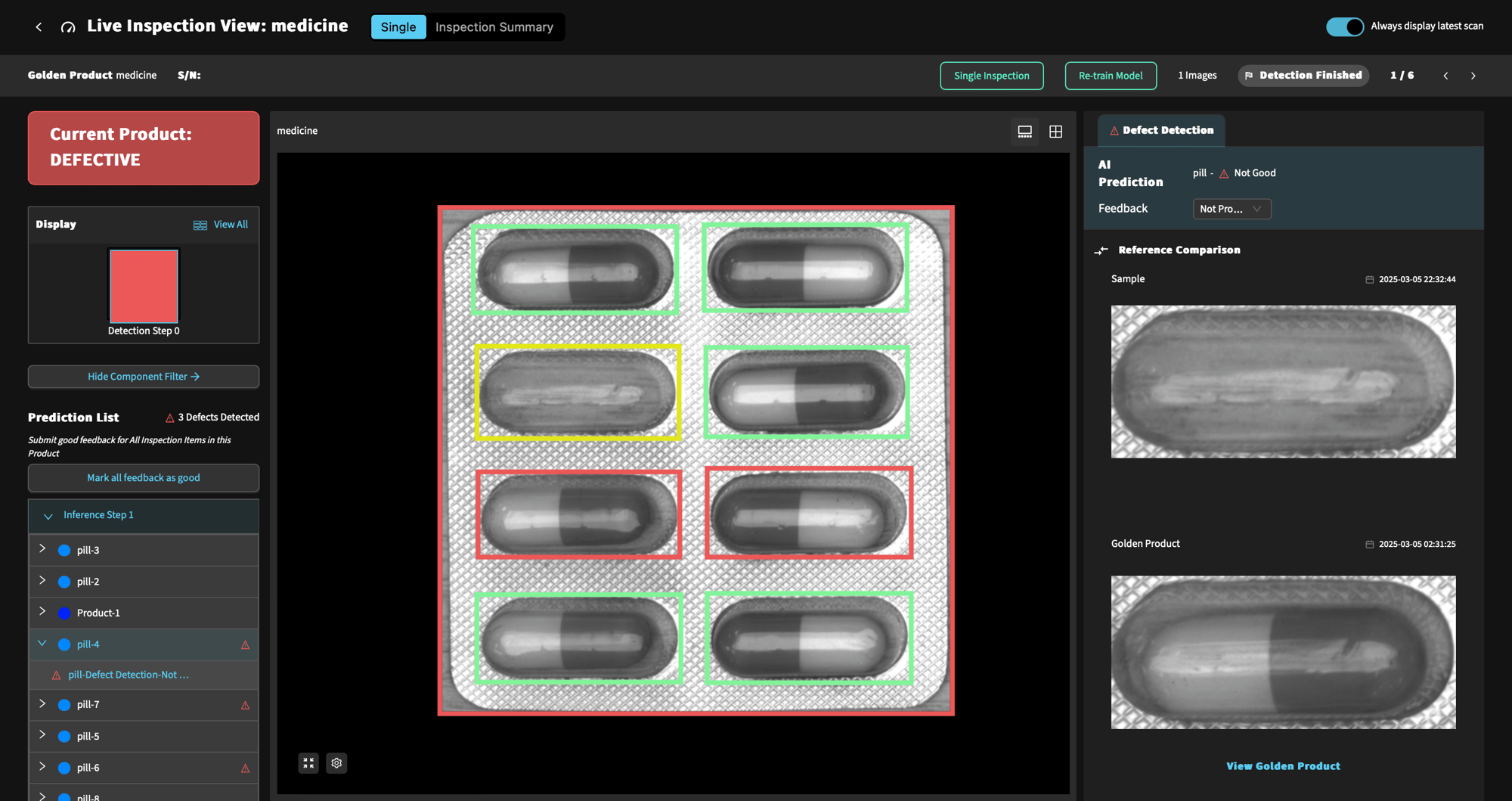

In rare cases, if there is an overkill/false detection, user can manually mark the selected area/part as the correct state.

As shown in the figure, if there is an overkill situation, simply mark the specified area as Good. You can also use the one-click function on the left to mark all selected areas as Good at once.

If there is an error or omission (as shown in the figure), mark that specified area as NG. Then, use the tool to highlight the errors, such as capsule breakage, packaging damage, or incorrect orientation.

Upon completion, you can click to retrain the model. We recommend that if there are special circumstances, the above review steps can be repeated multiple times to ensure maximum performance.

Just as humans learn from mistakes, the DaoAI AOI system can seamlessly integrate human feedback and retrain the model at high speed, so that the model can be continuously updated throughout inspection. This mechanism ensures that the accuracy of the system continues to improve over time.

Summaries

- Zero-defect sample dependence: Only 1-20 high-quality non-defective samples are needed to complete the construction of an AI models, solving the core pain points of the pharmaceutical industry, such as the high cost of defect data reproduction and the inconvenient collection and labeling process.

- Ultra-high-speed and accurate detection: a single detection area only needs 10 milliseconds of detection speed, with an initial accuracy of 99.7% (far exceeding the traditional AOI). The evolving feedback loop learning mechanism meets the needs of high-quality and efficient detection.

- Unknown Defect Capture: Excellent performance against potential unknown defects such as abrasion, scratches, foreign body contamination, etc., through unsupervised anomaly detection algorithms.

Upload your product sample or communicate with our technical team. We will provide you with intelligent test reports, and AOI will revolutionize drug packaging inspection for your company.