DaoAI Story

Moreover, issues such as tiny defect sizes and environmental interference make the detection process both complex and time-consuming. DaoAI provides a solution for keyboard manufacturers by identify unknown defects through using only positive samples. Combined with high-precision imaging and image preprocessing, this approach reduces sample collection costs while effectively overcoming challenges like subtle and inconspicuous defects, significantly improving overall detection efficiency.

Detection Challenges

The keyboard market today is highly diverse, ranging from standard keyboards to mechanical keyboards, membrane keyboards, and ergonomic keyboards. Each type of keyboard has different specifications and molds, with variations in the number, layout, shape, and size of keycaps. This makes it extremely difficult to segment and identify individual keycaps. Traditional detection methods struggle to meet such complex and diverse inspection requirements, especially when rapid detection is needed on large-scale production lines.

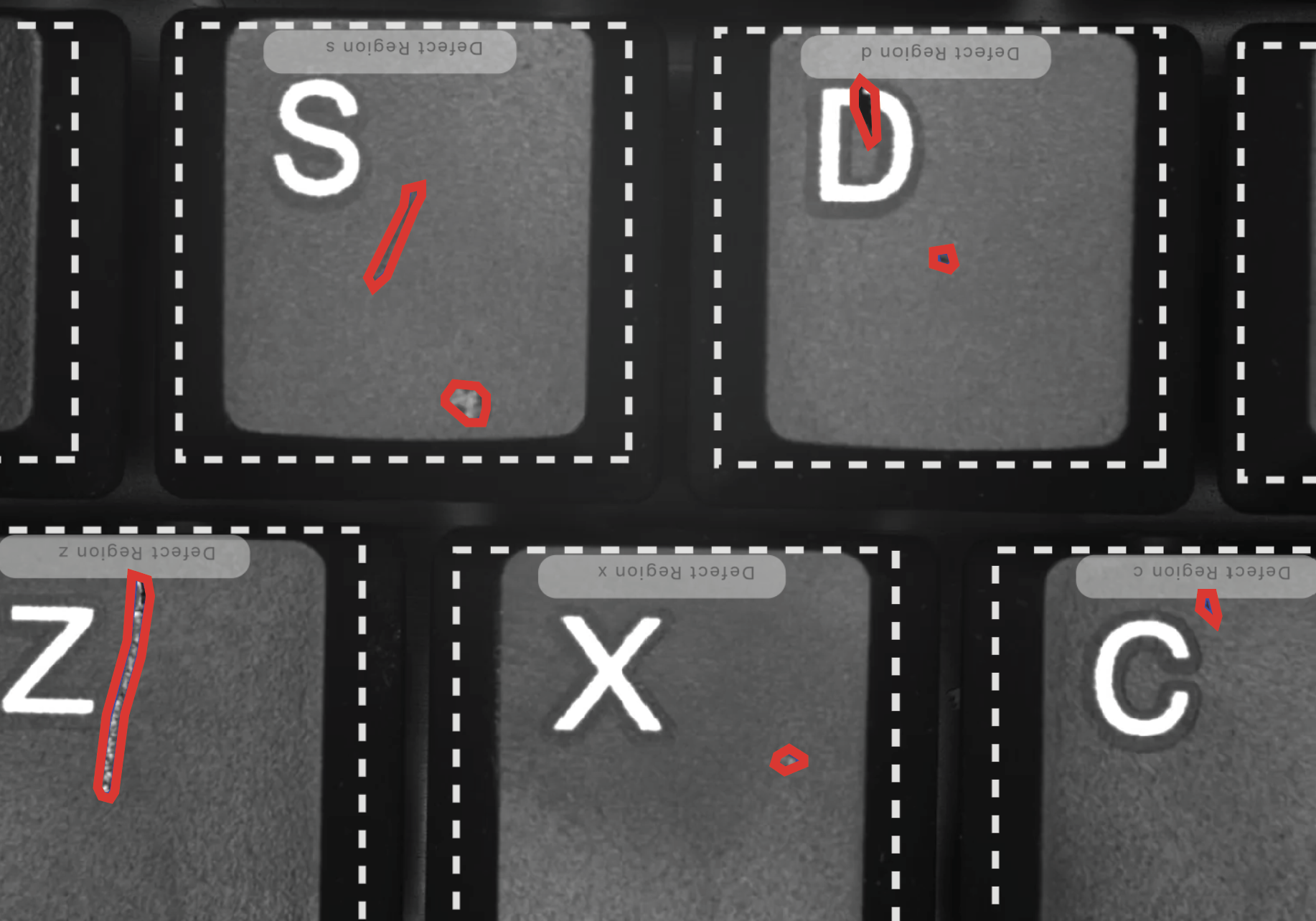

During the manufacturing process, keycaps may develop various tiny defects, such as barely visible scratches, dents, and bubbles. Under an 8K-resolution line-scan camera, the smallest defect may measure as little as 9 pixels on one side. These minuscule defects may not be prominent in images, making them easy to overlook or misjudge. This imposes extremely high demands on the precision and sensitivity of the detection system. Traditional inspection methods often fail to accurately identify these tiny defects, leading to detection inaccuracies.

Despite various measures taken to minimize dust and other contaminants in keyboard production lines, it is impossible to completely eliminate dust. Dust particles may settle on the surface of keycaps, creating white speck-like interference that can be mistaken for actual defects during detection. This increases the complexity and difficulty of the inspection process. Accurately identifying keycap defects while accounting for dust interference remains one of the key challenges in keyboard quality inspection.

DaoAI Solution

In real-world applications, DaoAI AOI system learns only from single positive samples to understand the standard characteristics of a product. During inspections, any detected anomalies are marked as potential defects for operators to review and confirm. If verified as actual defects, the system allows training personnel to highlight the defective area, ensuring future inspections prioritize these features. Similarly, if a false positive occurs, the platform provides a one-click feedback option to classify the anomaly as a normal sample, preventing unnecessary false alarms and optimizing model performance.

Paired with DaoAI’s specialized high-resolution cameras, the system captures the finest details of keycaps, ensuring that even the smallest defects are accurately detected. Also enhancing detection accuracy and reliability by highlighting keycap’s structural and defect features, segmenting key areas, reducing background interference, and improving image contrast.

The DaoAI AOI system is designed to handle the complexity of detecting large volumes of keycaps across various keyboard types. It can automatically classify and inspect different keyboard models, significantly boosting detection efficiency. To further optimize performance, the system builds a diverse keyboard model database, covering various keyboard types, keycap shapes, and sizes to meet different inspection needs.

The DaoAI AOI system delivers ultra-fast, precise detection, completing inspections within milliseconds per keycap with an initial model accuracy exceeding 99%. Its unique feedback learning mechanism allows AI to learn from mistakes, updating anomaly data in real time and rapidly iterating the model to keep pace with high-speed production lines.

On actual production lines, DaoAI AOI integrates with automated control systems (e.g., Siemens EasyCube) to synchronize assembly and inspection processes. During fast-paced production, the system enables seamless defect detection, rechecking, and correction, ensuring that every keycap is inspected before advancing to the next stage. As an all-in-one platform, it centralizes data management and provides visualized quality monitoring charts, allowing manufacturers to trace defects, adjust production parameters, and maintain stable operations on the production line.

The DaoAI AOI system offers an efficient solution for keyboard inspection through its self-developed AI model, combined with high-precision imaging and a feedback mechanism. It effectively addresses challenges such as the wide variety of keyboards, tiny defects, and complex production environments, ensuring accuracy, performance, and reliability in defect detection.

By implementing the DaoAI AOI system, keyboard manufacturers can enhance production efficiency, improve product quality, and reduce manufacturing costs—ultimately delivering higher-quality, more reliable keyboards to users.

Contact us now to create a tailored AI visual inspection solution for you!