From 3 Hours to 5 Minutes

The End of Programming Bottlenecks

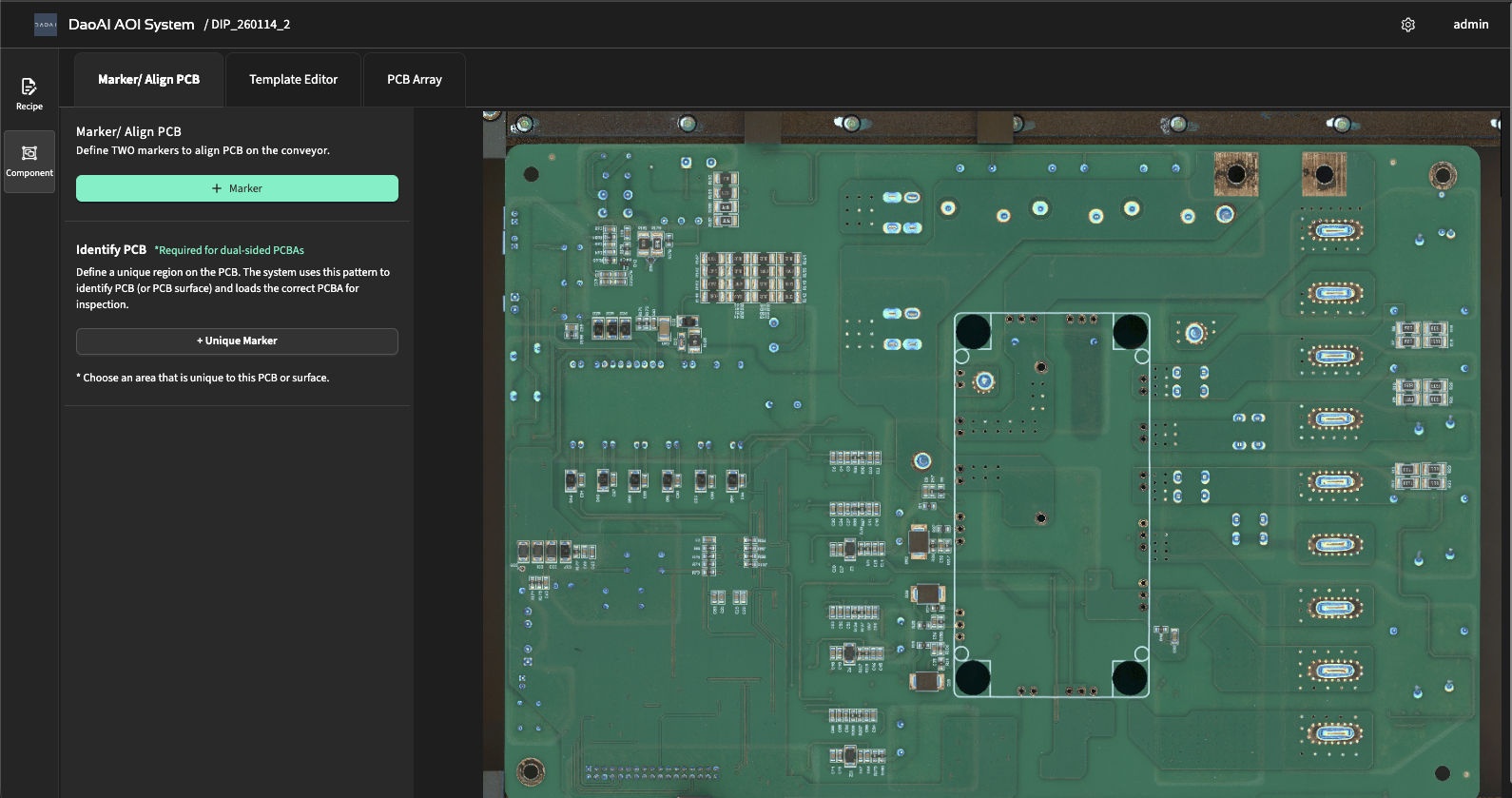

Rapid Scan

Scan one 'Golden Board'. No CAD files or component library required.

AI Mapping

Our proprietary AI auto-locates components, pins, and polarity in seconds. Save time on drawing bounding boxes.

Autonomous Rules

AI auto-generates inspection thresholds based on "Golden Sample".

Inspection Ready

Operator training: < 30 mins.

See It in Action

Discover DaoAI's Latest Innovations

March 17 - 19, 2026 | Anaheim Convention Center #2747, USA

Calculate Your ROI Savings

See how much you can save with DaoAI's AI-powered AOI solution

Cut Labor Costs

Save USD 28,000 – 42,000 per line every year.

Empower Operators

Move setup from 'Engineer-only' to 'Operator-ready' in 30 minutes.

Maximize Uptime

Turn hours of idle machine time back into profitable production.

Your Factory Metrics

Your Annual Savings Potential

Based on Your Metrics:

Based on your metrics, you currently spend annually on AOI programming across your SMT lines.

With DaoAI's AI-powered solution, you can save 40–60% of your AOI programming time. This means:

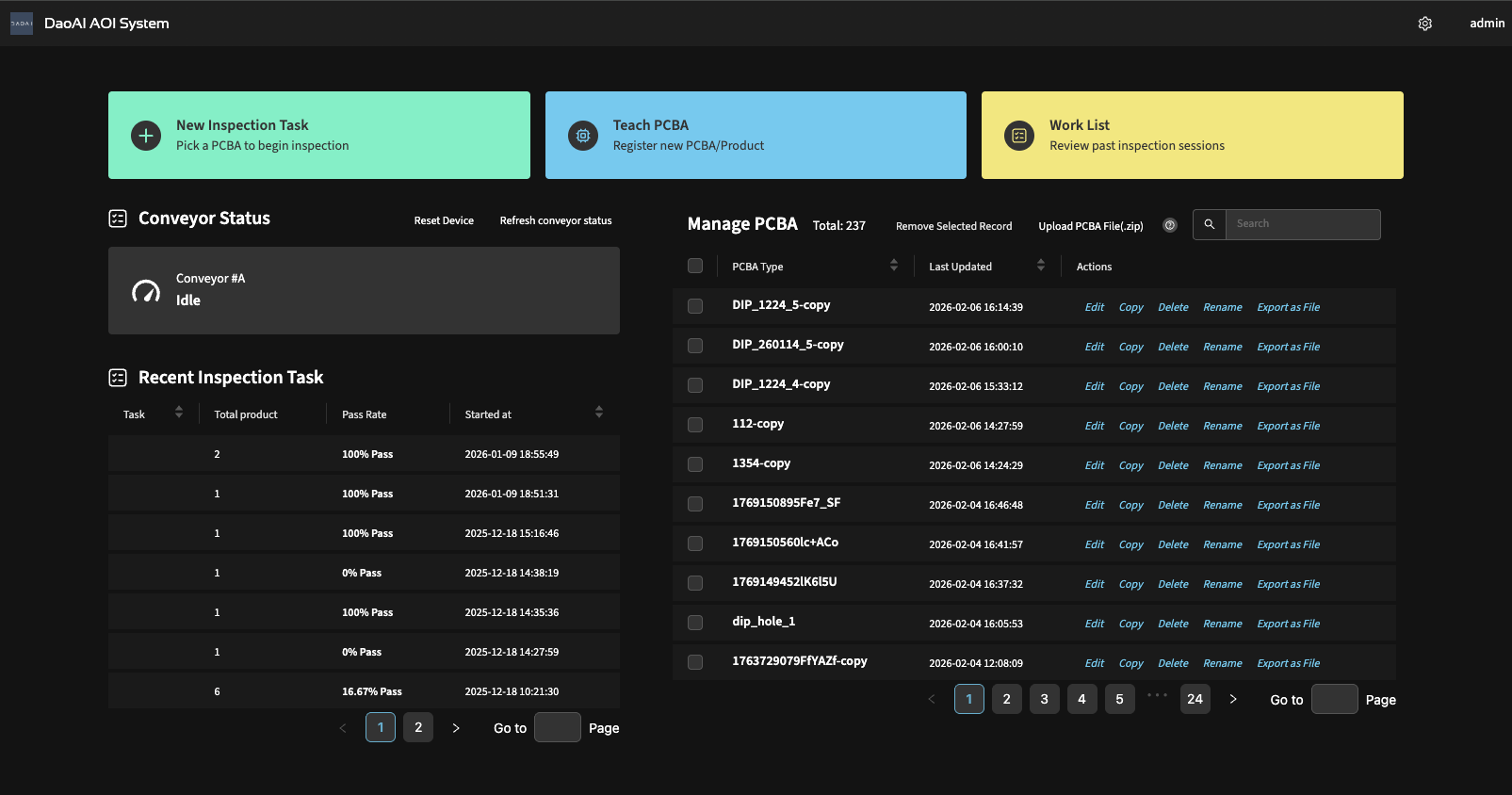

Powered by DaoAI SMT Visual AI

The AI Brain Behind the Machine

Auto BOM Matching

Instantly sync scanned components to your BOM. No manual library creation.

Semantic False Call Filter

Intelligently distinguishes between 'Acceptable Variations' (oxidation, vendor font changes) and real defects.

Real-Time SPC Dashboard

Monitor defect trends, yield rates, and MES integration from a single interface.

One Interface for Everything

- Program new boards in same UI

- Review flagged defects inline

- Export reports to MES

- Multi-language support (EN/CN)

Detects All Component-Level Defects

Missing/Wrong Part

Tombstone

Polarity / Flipped

Solder Bridge

Misalignment

OCR

Foreign Object

Insufficient Solder

Engineered for Synergy. Built for Flexibility.

Uncompromised Throughput Technology

1 ms /component

Millisecond-level Inspection

Instantly detects missing parts, wrong components, and polarity on high-density boards without computing bottlenecks.

45 cm²/s

Throughput

Perfectly matches the rhythm of High-Mix Volume SMT lines, eliminating post-reflow inspection bottlenecks.

CPU/GPU

Parallel Processing Architecture

GPU focuses on processing complex defects and OCR, while the CPU synchronously handles logic operations. True parallel processing ensures tasks do not wait for each other, maximizing hardware efficiency.

| Specification | P1 / P2 (Offline) | P3/P3D (Inline) |

|---|---|---|

| Ideal For | High-Mix Volume | High-Volume SMT Lines |

| Camera / Res | 5MP (15µm) / 12MP (10µm) | 20MP (10µm) |

| Imaging System | Dual Telecentric Lens | 20MP Telecentric Lens |

| Lighting | Multispectral RGB 6-Channel | High-intensity RGB Coaxial + multi-angle ring LED Ring |

| Max PCB Size | 470 × 330 mm | 500 × 325 mm |

| Conveyor | Manual Load / Unload | Single Track (P3) / Dual Track (P3D) |

What is the 'NPI Paradox'?

How does DaoAI SMT Visual AI differ from Traditional AOI?

Do I need a 'Golden Board'?

Can it work with CAD files?

Offline 2D AI AOI Machine

DaoAI P1 & P2

DaoAI P1& P2 leverages advanced visual AI to automate PCBA inspection programming. By learning directly from golden sample, it auto-detects components, generates bounding boxes, and defines defect thresholds — accelerating setup from hours to 5 minutes.

DaoAI P1/P2 Specifications

DaoAI P1

5MP0 Camera /month

DaoAI P2

12MP0 Camera /month

DaoAI P1

DaoAI P2

Optical System

Conveyor & PCB Size

Inspection Capability

Additional Functions

Inspection and Auto-Configuration Capabilities

|

Body |

Polarity | IC Leads |

Text

|

|

|---|---|---|---|---|

|

Capacitor |

|

|

|

|

|

Resistor |

|

|

|

|

|

Multilayer Chip Inductor |

|

|

||

|

Aluminum Electrolytic Capacitor |

|

|

|

|

|

Tantalum Capacitor |

|

|

|

|

|

Resistor Array |

|

|

|

|

|

Power Inductor |

|

|

||

|

LED |

|

|

|

|

|

SOT/SOD |

|

|

|

|

|

SOIC/SOP/TSOP/TSSOP/MSOP |

|

|

|

|

|

QFP |

|

|

|

|

|

QFN |

|

|

||

|

TO-263/TO-252 |

|

|