DaoAI Story

Feb, 2025. Vancouver

Revolutionizing Industrial Automation

In the era of Industry 4.0, manufacturers are continuously seeking innovative solutions to enhance efficiency, minimize defects, and optimize production workflows. By integrating Workflow Canvas™ with DaoAI’s high-precision Automated Optical Inspection (AOI) system, manufacturers can unlock unprecedented levels of automation and intelligence in their production lines.

Seamless Automation with Workflow Canvas™

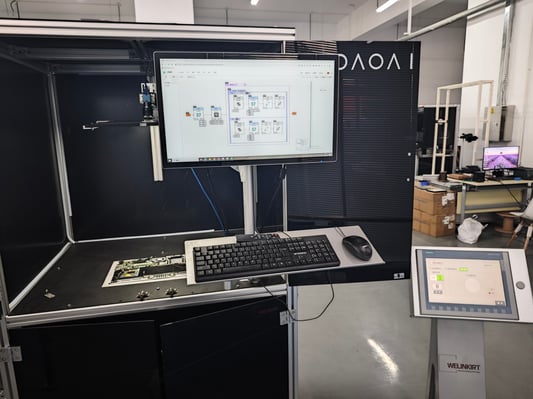

Siemens’ Workflow Canvas™ provides an intuitive graphical workflow design platform, enabling users to drag and drop modular components to create seamless workflows—from inspection to defect resolution.

- PLC Initiates Inspection: The PLC system sends an inspection request to Workflow Canvas™, which then orchestrates the workflow.

- AOI System Execution: Workflow Canvas™ forwards the request to DaoAI’s AOI system, which performs high-precision inspections.

- Inspection Analysis: The AOI system captures images, analyzes the data, and detects anomalies such as assembly misalignment or defects.

- Decision Making: Based on the results, the system determines whether the product is OK or NG (No Good).

- Automated Action & Feedback: The results are relayed to Workflow Canvas™, which then sends corrective actions to PLC or other connected equipment to execute necessary adjustments, completing the automation loop.

Case Study: Fully Automated Laptop Inspection

- Screw height discrepancies

- Connector alignment precision

Once the AOI system completes its inspection, Workflow Canvas™ aggregates the results and automatically triggers corrective actions. For instance, robotic arms are instructed to make real-time adjustments, ensuring a fully automated quality control workflow.

Designed for industrial automation, DaoAI’s AI-driven AOI System revolutionizes defect detection with:

- Ultra-fast detection – Each region is inspected in just 10 milliseconds, leveraging advanced image optimization algorithms to detect microscopic details as small as 4x4 pixels.

- Unmatched accuracy – Initial models achieve up to 99.7% precision, with defect miss rates and false positives both below 1%.

- All Positive Data Training – The AI model requires as few as 1-20 images to learn and can be rapidly deployed in real-world environments.

- Self-learning feedback loop – Mimicking human learning, the system continuously improves by integrating operator feedback into the training process.

- Real-time inference – AI-powered defect detection occurs instantly, ensuring seamless integration with production lines.

- Broad compatibility – Supports PLCs, mainstream industrial control systems, and GigE/USB3 industrial cameras for flexible deployment.

Seamless Integration via Siemens Xcelerator

DaoAI’s AOI System is now available on the Siemens Xcelerator platform, allowing manufacturers to purchase and integrate it effortlessly. Additionally, DaoAI offers custom AI model development services tailored to specific industrial applications, including automotive manufacturing, electronics assembly, and more.

Contact our business and technical team today to build a fully customized vision inspection solution for your production needs.