No need for defect-rich datasets. DaoAI’s proprietary model overcomes lighting and color variation issues, helping clients deploy visual inspection quickly and effectively.

The real challenge in defect detection isn't the model—it's the data.

- Trouble collecting enough defect samples, making model training difficult?

- Once lighting or color conditions change, model performance drops dramatically?

DaoAI’s solution is designed specifically to solve these on-the-ground problems.

Our approach:

Train with just one good image—and still spot defects.

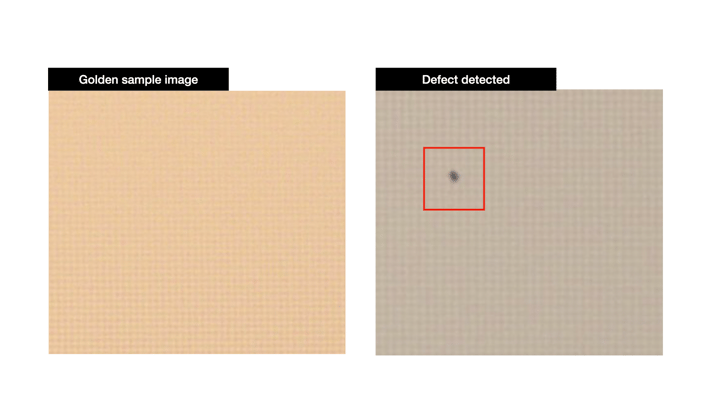

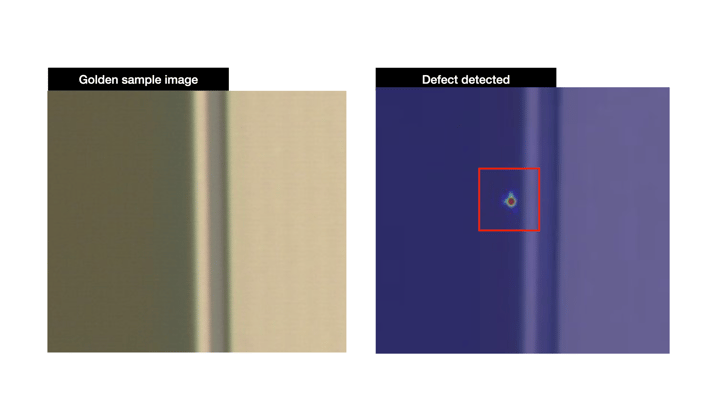

DaoAI's AOI system requires no defect images or manual annotations. By learning from a single "golden" sample image, the system automatically builds a baseline model and flags any area that deviates from the normal pattern—effectively identifying anomalies without prior defect examples.

5 Key Scenarios on Electronic Boards

- Lighting Variation Test In real production lines: Lighting conditions often change due to environmental factors.

Even with minor tone shifts, the model remained stable—key textures were preserved and correctly interpreted.

- Color Feature Variation: changes in PCB or coating colors due to batch differences.

The model demonstrated strong tolerance for color variation, maintaining accuracy without mistaking color shifts for defects.

- Key Region Defect Test (e.g., busbar areas) We targeted critical functional zones to see if the model could focus on relevant anomalies without interference.

The unsupervised model successfully highlighted abnormal areas, aligning well with actual defect locations.

- Electrode Area :Test Electrode regions often have low contrast and subtle variations.

- Position Shift: Would minor shifts in component position affect detection?

Yes—location deviation did reduce accuracy. However, with proper preprocessing, the model's performance could be significantly enhanced.

DaoAI’s AOI System performs reliably even without defect images and under highly variable field conditions. It’s a practical solution built for electronics assembly, PCB inspection, and modular production lines, enabling fast deployment with minimal data requirements.

- Rapid technical assessments

- Demo model testing

- Guided trials

- deployment consultation

FAQ

1. What makes DaoAI’s defect detection system different from traditional AI models?

DaoAI’s system eliminates the need for defect-rich datasets and manual annotations. By training on a single “golden” image, it creates a baseline to detect anomalies, saving time and reducing the data burden typically required by traditional AI models.

2. Can DaoAI’s AOI system handle changes in lighting and color conditions?

Yes. DaoAI’s proprietary model is built to be resilient to variations in lighting and color. It maintains high accuracy even when tone or PCB colors shift, which is common in real production environments.

3. How does DaoAI detect defects without any labeled data?

The system uses unsupervised learning, relying on one defect-free image. It then flags any pixel or pattern deviations from this standard image as potential defects, effectively identifying anomalies without needing defect samples or human labeling.

4. Does the model work on key areas like busbars or electrode zones?

Absolutely. DaoAI’s system has been tested on critical zones such as busbars and electrode areas—regions typically challenging due to subtle variations—and has consistently detected fine-grained anomalies in these complex zones.

5. Who is DaoAI’s AOI system best suited for?

This solution is ideal for electronics manufacturers, PCB inspectors, and assembly lines needing fast deployment, minimal training data, and robust performance in dynamic production conditions.