AI-Powered Assembly Inspection Solutions

Elevate your manufacturing quality with intelligent inspection systems designed for diverse industries.

Rapid Model Training

Create inspection models in just 30 seconds using a single golden sample image—no defect samples required.

User-Friendly Operation

Intuitive interface allows for quick setup and operation without the need for programming skills.

High Detection Accuracy

Achieve over 99.97% accuracy with comprehensive defect coverage and zero missed detections.

Seamless Production Line Integration

Easily integrate with existing production lines without the need for modifications.

Continuous Algorithm Optimization

Our real-time optimization mechanism continuously enhances detection performance.

Web-Based Operation

Manage camera configurations and data through a unified web interface, supporting efficient remote access.

Versatile Detection Capabilities

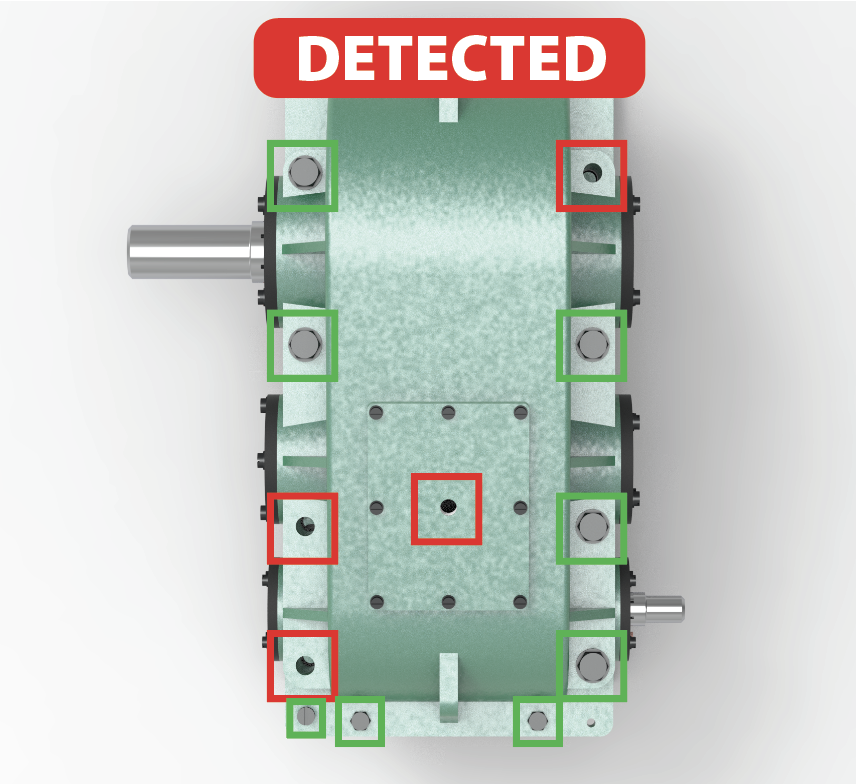

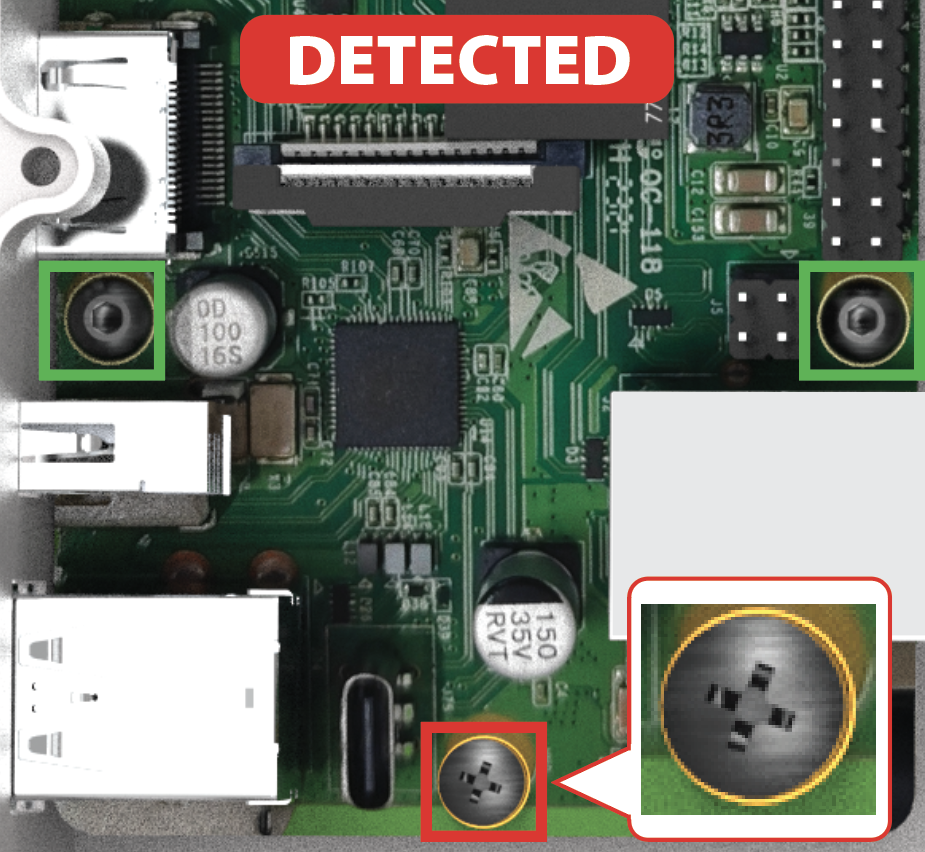

3D Component Tilt Detection

Identify angular deviations in components like screws to ensure assembly precision and stability.

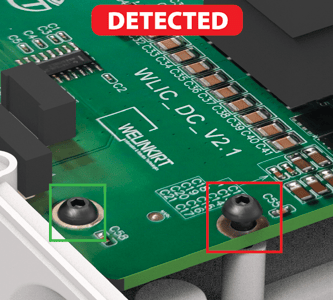

Reflective Object Inspection

Specialized AOI algorithms detect defects on reflective and dark-colored surfaces.

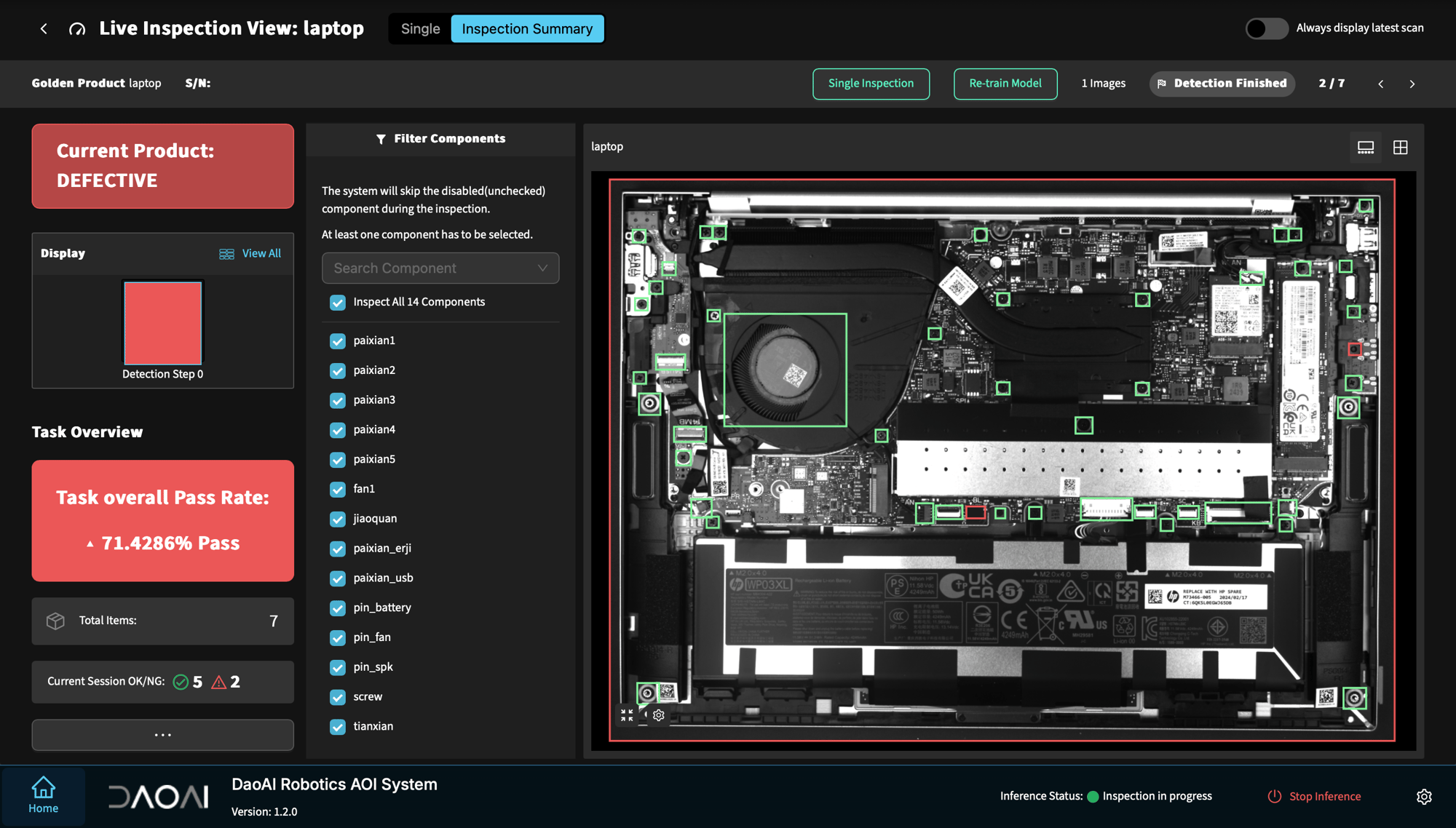

Comprehensive 2D Inspection — From Missing Parts to Misalignments

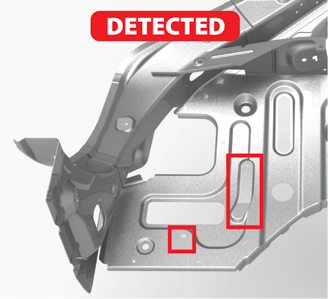

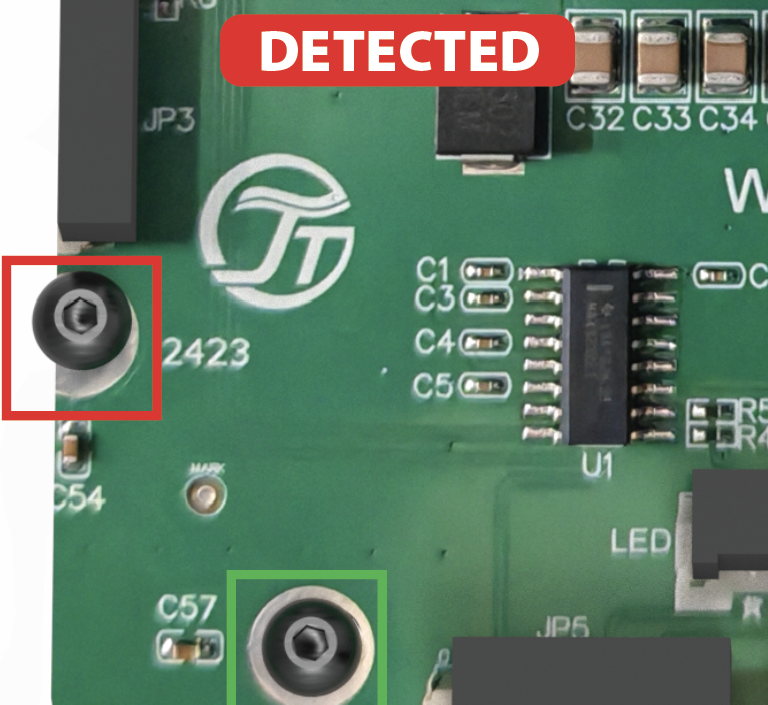

2D Component Absence Detection

Detect missing or improperly assembled key components to ensure structural integrity.

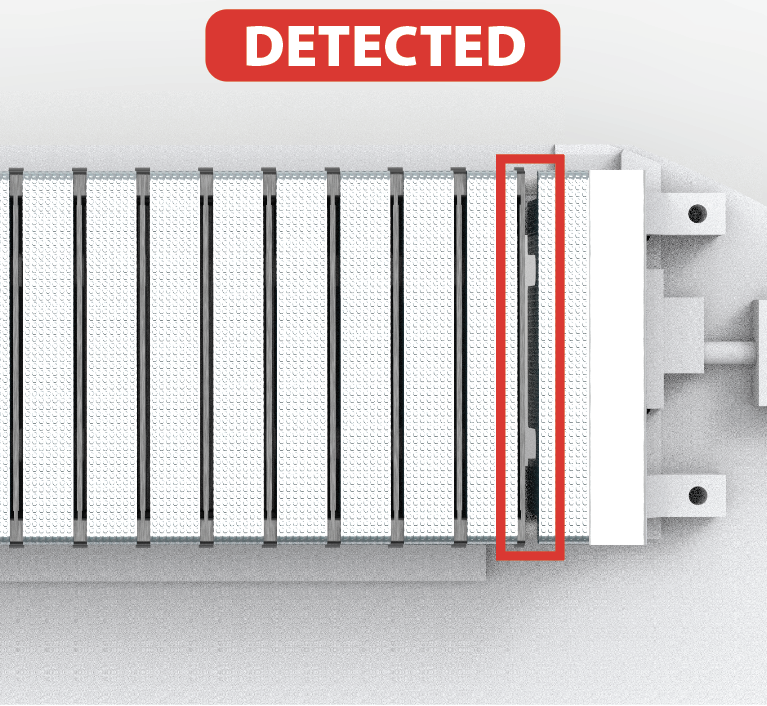

2D Assembly Anomaly Detection

Accurately identify misalignments, missing, or uninstalled components in module arrangements.

2D Position Verification

Detect dimensional deviations, misalignments, or incorrect angles in components.

Foreign Object/Wrong Material Detection

Surface Defect Detection

Detect scratches, cracks, and other surface imperfections on plastic housings.

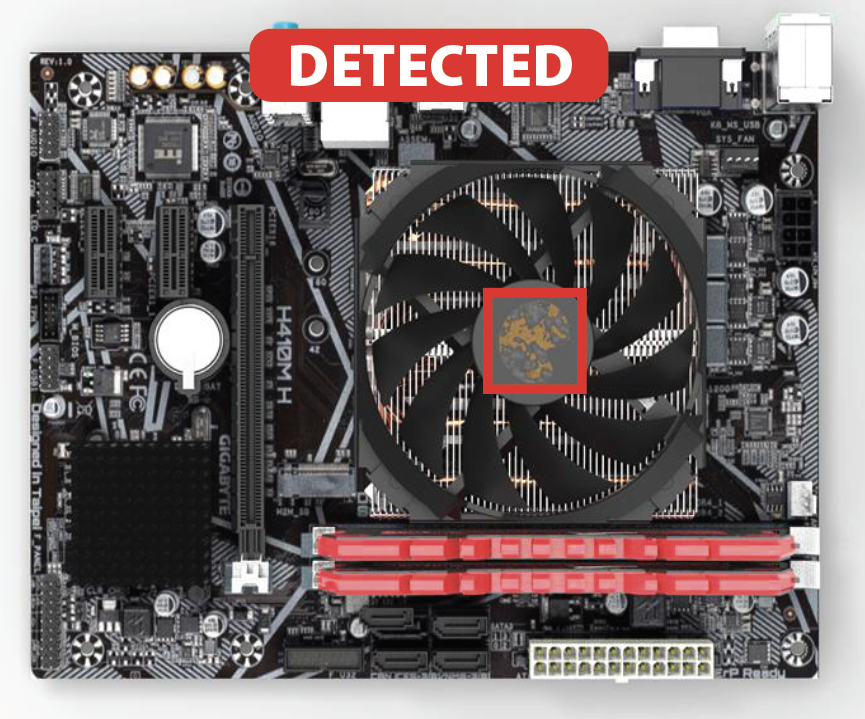

Surface Contamination Detection

Detect oil stains, dust, and other contaminants on component surfaces.

Key Functionalities Driving Intelligent Inspection

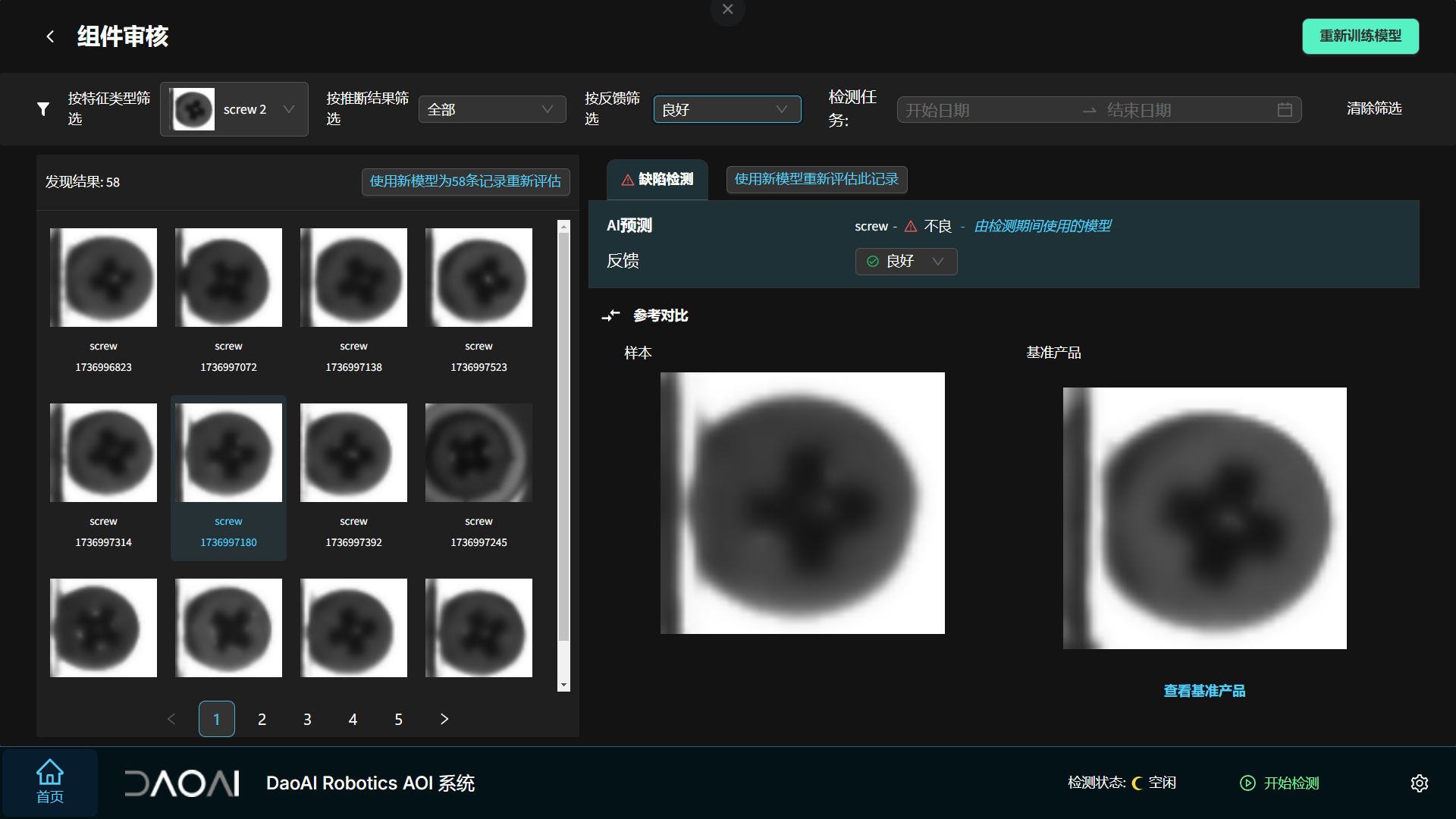

Component Review

Assess overall component quality levels and adjust production lines accordingly, supporting filtering by component features and inference results.

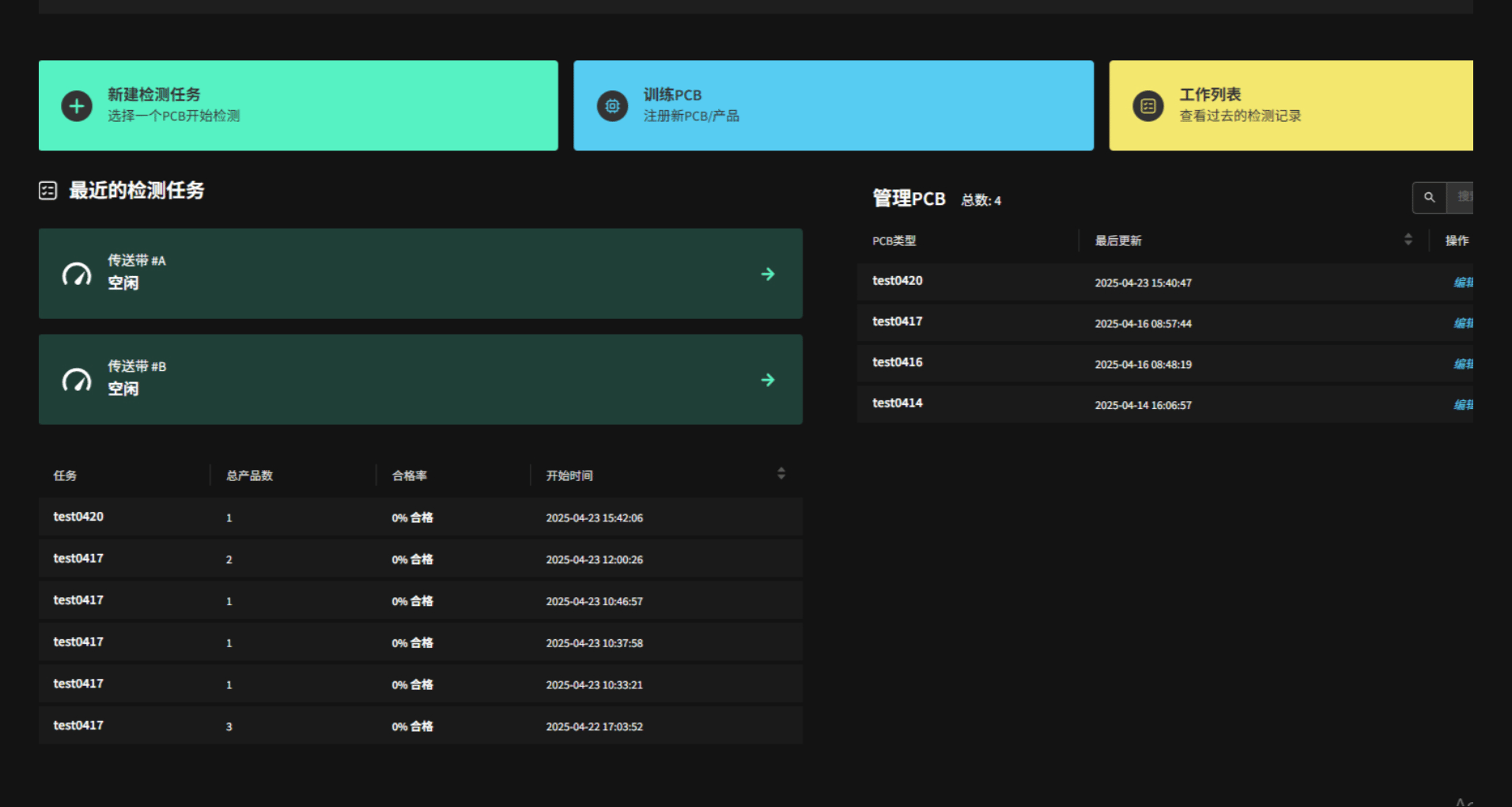

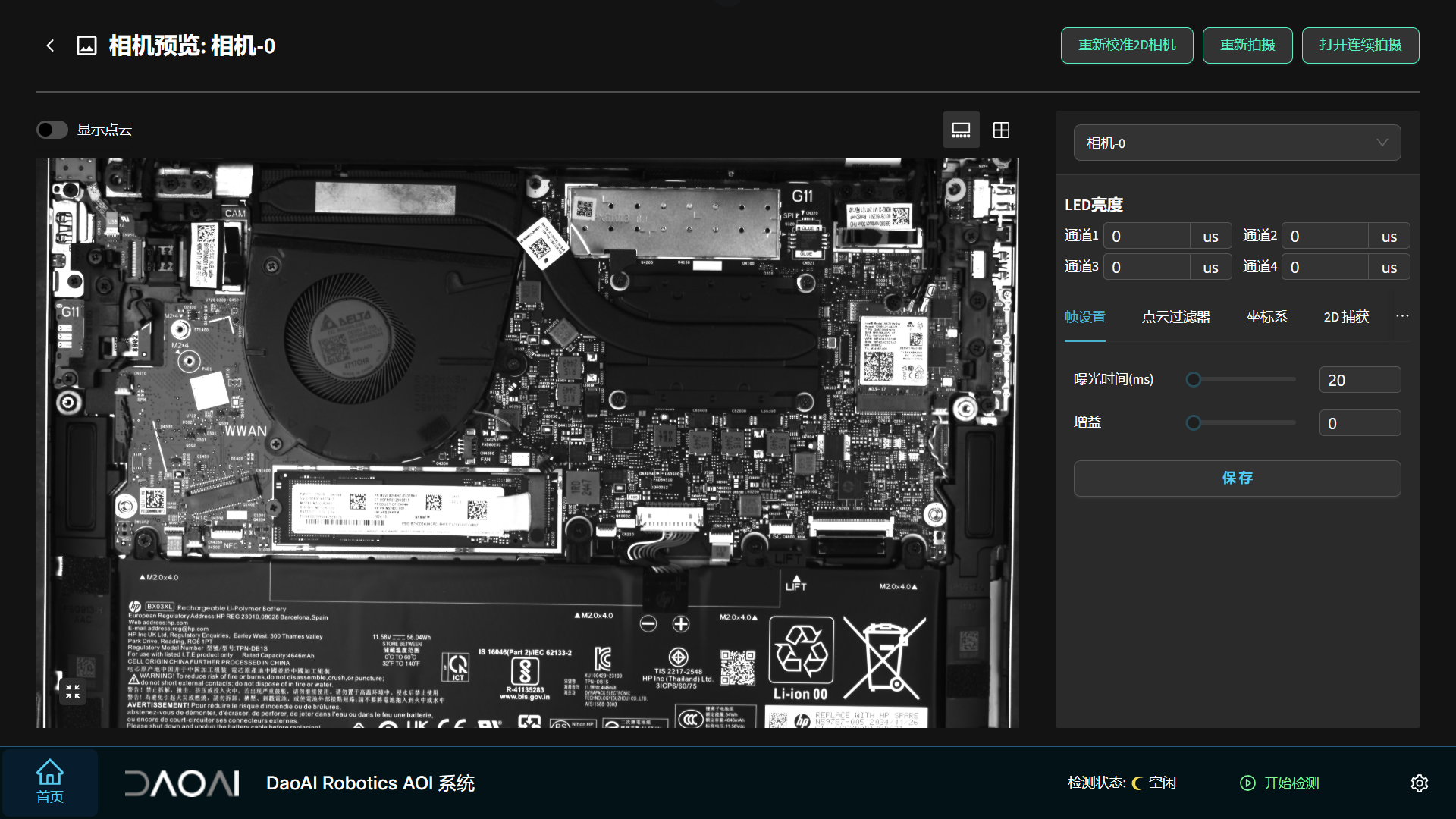

Browser-Based Operation

Camera configuration and data management are integrated into a web interface, eliminating the need for multiple software tools and supporting efficient remote access.

Inspection Result Overview

Identify defects in specific products with AOI providing search functionality by product name or serial number.

Customizable Camera Parameters

Users can adjust camera parameters based on different environments to achieve optimal results.

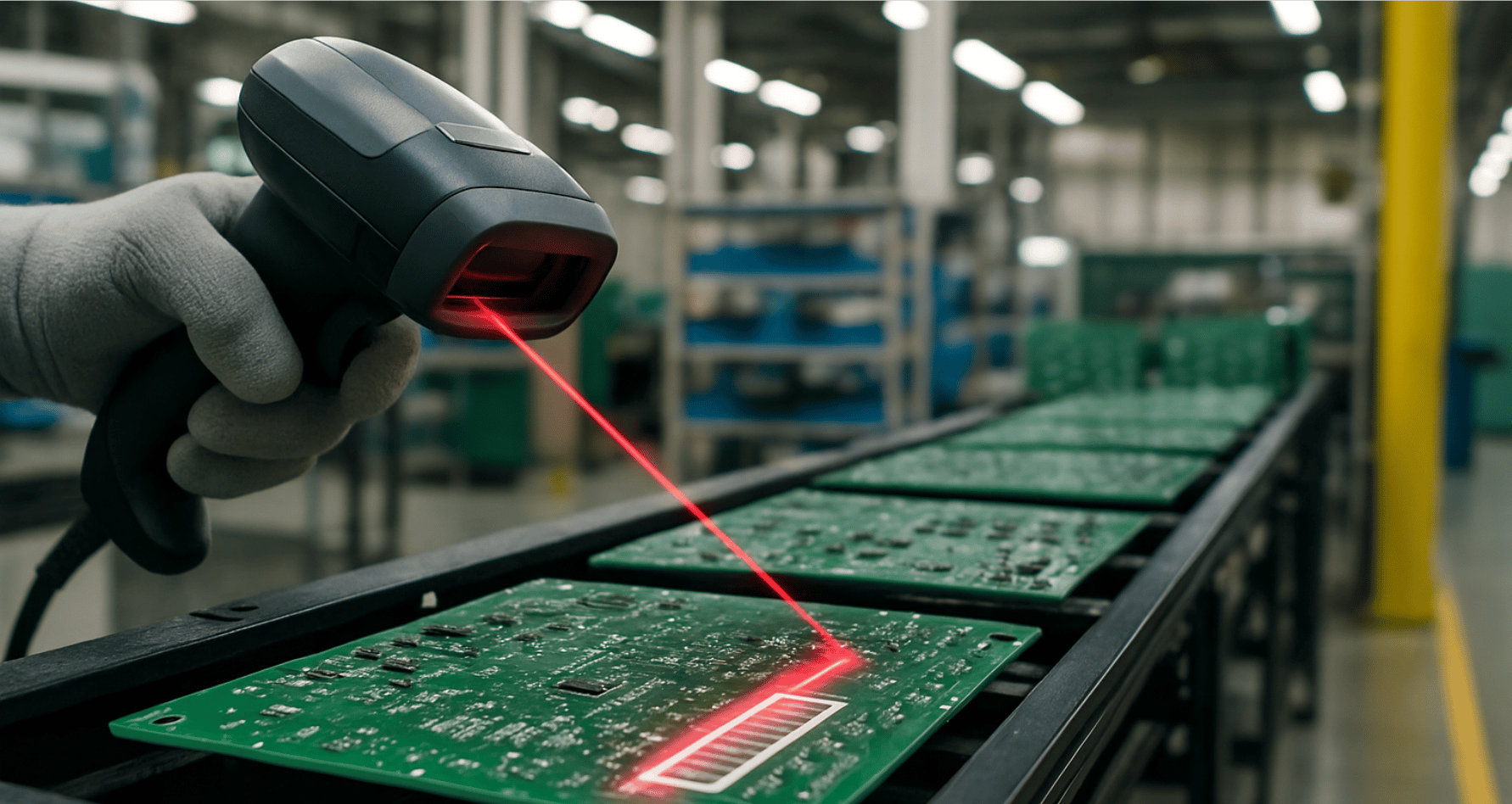

QR Code Reading

Supports communication with external barcode scanners for scanning QR codes to obtain information.

Modbus Communication Support

Connect devices via the Modbus protocol to ensure stable data transmission, strong compatibility, and ease of industrial system integration.

Efficient AI Training and Continuous Improvement

Our proprietary training mechanism eliminates the need for extensive defect image datasets. By using flawless samples, we can train high-precision detection models, accelerating deployment and facilitating seamless production line integration.

-

No defect samples required.

-

No need for defect annotation in training models.

-

Zero missed detections with 100% comprehensive defect coverage.

When anomalies are identified, on-site personnel can confirm and provide corrective feedback, optimizing the model for increased accuracy over time.

- Model optimization training completed within 1 minute.

- Closed-loop optimization achieves over 99.97% accuracy

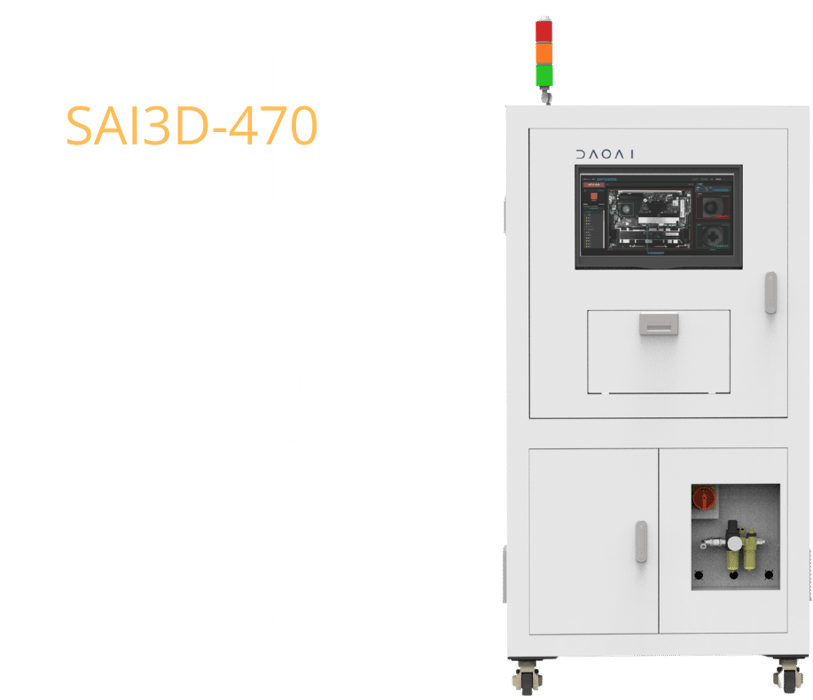

SAI3D-470 Technical Spec

| SAI3D-470 | |

|

Conveyor Height |

750±20mm |

|

Conveyor Width |

400mm |

|

Drive System |

Z-axis with 100mm stroke screw manual adjustment |

|

Track Direction |

Left to right, right to left (customizable) |

|

Positioning Device |

Equipped with XY direction, bidirectional positioning device; Z direction manually adjustable |

|

Power Supply |

220V±10%,50/60Hz |

|

Dimensions |

850*900*1655 mm (excluding three-color alarm light) |

|

Display |

21.5nches |

|

Status Indicator Light |

Three-color light + buzzer |

SAI2D-500 Technical Spec

| SAI2D-500 | |

|

Conveyor Height |

750±20mm |

|

Conveyor Width |

400mm |

|

Drive System |

Z-axis with 100mm stroke screw manual adjustment |

|

Track Direction |

Left to right, right to left (customizable) |

|

Power Supply |

220V±10%,50/60Hz |

|

Dimensions |

850*850*1650 mm (excluding three-color alarm light) |

|

Display |

21.5inches |

|

Status Indicator Light |

Two-color light + buzzer |

Camera Spec

| SAI3D-470 | SAI2D-500 | |

|

Camera |

18MP High-speed Camera(DaoAI AD-470) |

20MP high-speed camera |

|

FOV |

477 x 435 mm |

500 x 400 mm |

|

Optical Resolution |

0.11mm |

0.1mm |

|

Working Distance |

510 +- 50mm |

400-500mm |

|

3D Technology |

Dual-direction structured light projection |

Central hole surface light |